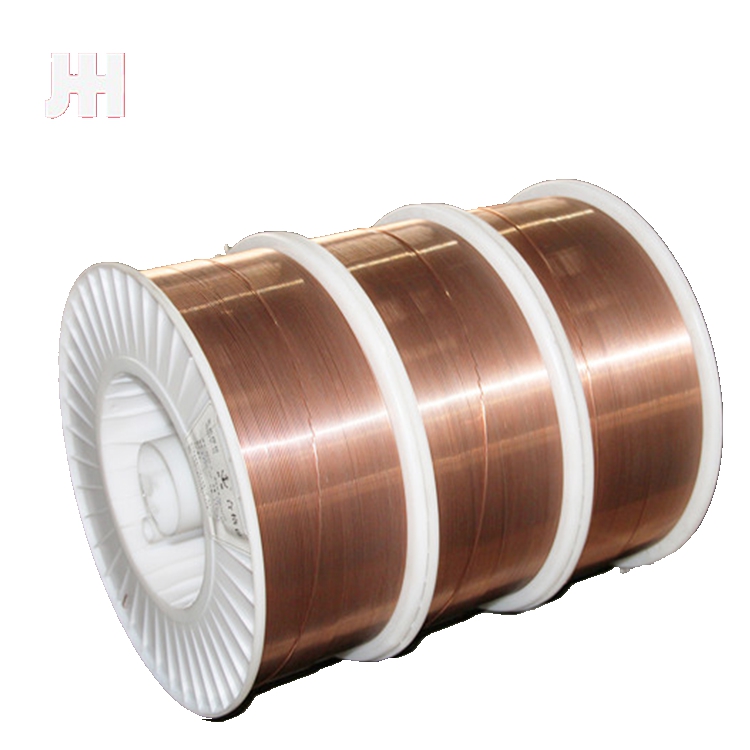

wholesale arc welding electrodes factory

The Rise of Wholesale Arc Welding Electrodes Factories

In recent years, the demand for arc welding has soared across various industries, ranging from construction and automotive to shipbuilding and manufacturing. Arc welding, a process that involves using electricity to create an arc between an electrode and the workpiece, requires high-quality electrodes to ensure reliability and efficiency. Consequently, the emergence of wholesale arc welding electrodes factories has become a critical component of the welding supply chain, providing businesses with essential materials at competitive prices.

What Are Arc Welding Electrodes?

Arc welding electrodes are crucial tools in the arc welding process. They serve as a filler material that melts during welding to create a strong bond between two metal pieces. There are primarily two types of electrodes used in arc welding consumable and non-consumable electrodes. Consumable electrodes, such as those made of coated metal, melt away during the process, while non-consumable electrodes, like tungsten, remain intact. The choice of electrode is determined by the specific welding process being used and the materials being joined.

The Role of Wholesale Factories

Wholesale arc welding electrodes factories play a pivotal role in streamlining the supply of welding materials. By producing electrodes in bulk, these factories can pass on significant cost savings to manufacturers and contractors. The benefits of purchasing welding electrodes from wholesale factories include

1. Cost Efficiency Buying in bulk reduces the per-unit price, allowing companies to maintain lower operational costs. This is particularly beneficial for businesses that rely on a steady supply of welding materials for ongoing projects.

2. Quality Assurance Reputable wholesale factories often adhere to stringent quality control processes, ensuring that their electrodes meet international standards. This reliability is crucial, as inferior electrodes can lead to project delays and increased costs due to rework and safety risks.

wholesale arc welding electrodes factory

3. Variety and Customization Wholesale manufacturers can cater to various industry needs by providing a diverse range of electrodes. This includes different sizes, coatings, and materials tailored for specific welding applications. Custom orders can also be accommodated, allowing businesses to get exactly what they need for their unique projects.

4. Accessibility Wholesale factories can typically ship products directly to clients, reducing the time and effort involved in sourcing materials. This ease of access is vital, particularly for large projects that require an immediate supply of electrodes.

5. Support and Expertise Many wholesale factories offer technical assistance, advising clients on the best electrode choices based on their specific welding applications. This support can prove invaluable, particularly for less experienced welders or companies entering new markets.

Conclusion

The advent of wholesale arc welding electrodes factories has transformed the way industries source their welding materials. As the demand for welding continues to grow, these factories will remain integral to providing high-quality, cost-effective solutions that meet various industry requirements.

Moreover, as technology evolves, the manufacturing processes for arc welding electrodes are becoming increasingly sophisticated. Innovations such as automated production lines and advanced materials are paving the way for even greater efficiency and reliability.

Companies looking to enhance their welding operations should consider establishing relationships with reputable wholesale electrode manufacturers. The right partnership can facilitate a steady supply of top-notch electrodes, ultimately contributing to successful projects and long-term business growth.

In summary, the wholesale arc welding electrodes factory is not just a provider of materials; it is a fundamental partner in industry innovation and efficiency. With the right electrodes, welding projects can achieve the quality and durability needed to withstand the trials of time and usage, reinforcing the importance of these factories in the modern industrial landscape.

-

J506 Welding Rod: High-Strength, Crack-Resistant ElectrodeNewsAug.23,2025

-

E71T-1 Shielding Gas for Superior Welding Quality & EfficiencyNewsAug.22,2025

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025