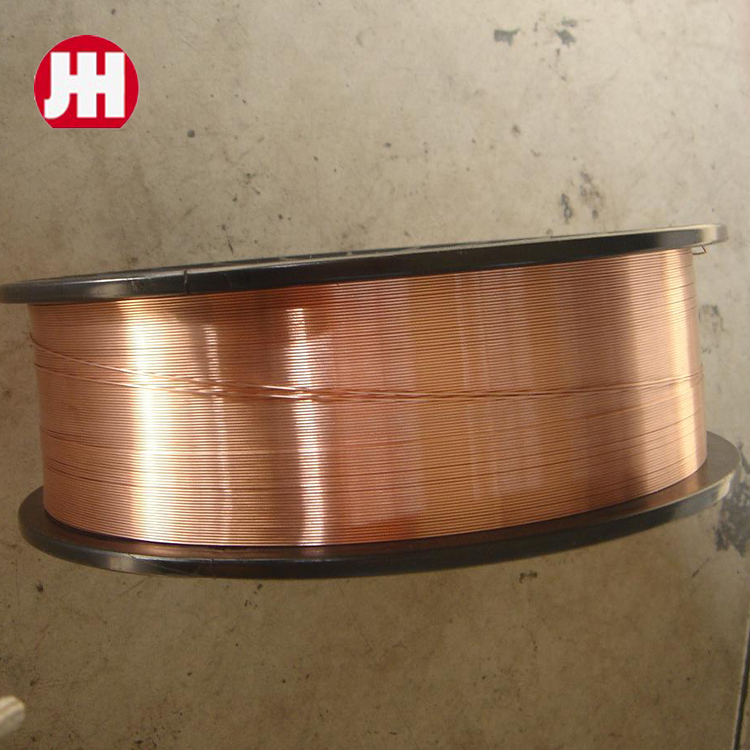

Wholesale 1.0mm MIG Welding Wire from Top Manufacturers for Quality Welding Solutions

Understanding Wholesale MIG Welding Wire A Comprehensive Guide

MIG welding, or Metal Inert Gas welding, is a versatile and widely used welding process that relies on a continuous wire feed, combined with a shielding gas, to create robust welds. The quality of the weld largely depends on the welding wire used, making the choice of purchasing from wholesale MIG welding wire factories an important consideration for both professional welders and hobbyists alike. In this article, we will explore the benefits of buying wholesale MIG welding wire, key factors to consider, and tips for selecting the right supplier.

The Benefits of Wholesale MIG Welding Wire

1. Cost Efficiency One of the primary advantages of purchasing MIG welding wire wholesale is cost savings. Wholesale suppliers often offer better rates compared to retail outlets, allowing businesses and individuals to buy in bulk at reduced prices. This is particularly beneficial for industries that require large volumes of welding wire.

2. Consistent Quality When sourcing from reputable wholesale factories, buyers can expect a consistent level of quality. Established manufacturers adhere to strict production standards, ensuring that every spool of welding wire meets specified criteria for chemical composition and mechanical properties. This consistency results in better welding performance and reduced defects.

3. Variety of Options Wholesale MIG welding wire suppliers typically offer a wide range of options, including different diameters, materials (such as stainless steel, mild steel, and aluminum), and coatings. This variety allows welders to choose the most suitable wire for their specific application, whether for automotive repairs or construction projects.

Key Factors to Consider When Buying MIG Welding Wire

1. Wire Composition The material composition of the welding wire significantly affects the quality of the weld. Depending on the project requirements, welders may need to select wires that are designed to work with specific metals or alloys. Common types include ER70S-6 for mild steel and ER308L for stainless steel.

wholesale mig welding wire 1.0 factories

2. Wire Diameter The diameter of the welding wire influences the heat input and penetration of the weld. Thicker wires (e.g., 1.0 mm) are ideal for larger gaps and thicker materials, while thinner wires are better for detailed work and thin sheets. It’s essential to choose a wire diameter that complements the welding machine and the materials being welded.

3. Shielding Gas Compatibility The type of shielding gas used can impact the wild's quality. Common shielding gases include Argon, Carbon Dioxide (CO2), and helium mixtures. Different wires may require specific gas combinations to achieve optimal results. Understanding the gas compatibility with the welding wire is crucial for achieving strength and durability in the weld.

Tips for Selecting the Right Wholesale Supplier

1. Reputation and Reviews Before committing to a supplier, it is important to research their reputation in the industry. Look for customer reviews, testimonials, and ratings that can provide insight into their reliability and the quality of their products.

2. Certification and Standards Ensure that the supplier adheres to relevant industry standards and certifications. This can include ISO certifications or other quality assurance processes that demonstrate a commitment to producing high-quality welding wire.

3. Sample Testing When possible, request samples of the welding wire before making a bulk purchase. Testing the wire's performance on a small scale can give you confidence in its suitability for your specific applications.

4. Customer Support A good wholesale supplier should offer excellent customer support. This includes answering any technical questions, providing guidance on product selection, and assistance in case of any issues with the orders.

In conclusion, purchasing wholesale MIG welding wire from reputable factories offers numerous advantages, including cost efficiency, consistent quality, and a diverse selection. By considering factors such as wire composition, diameter, and shielding gas compatibility, as well as choosing a reliable supplier with a proven track record, welders can ensure they have the best materials for their projects. Investing time in selecting the right MIG welding wire will ultimately lead to superior welding results and enhanced project success.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025