Vijesti

-

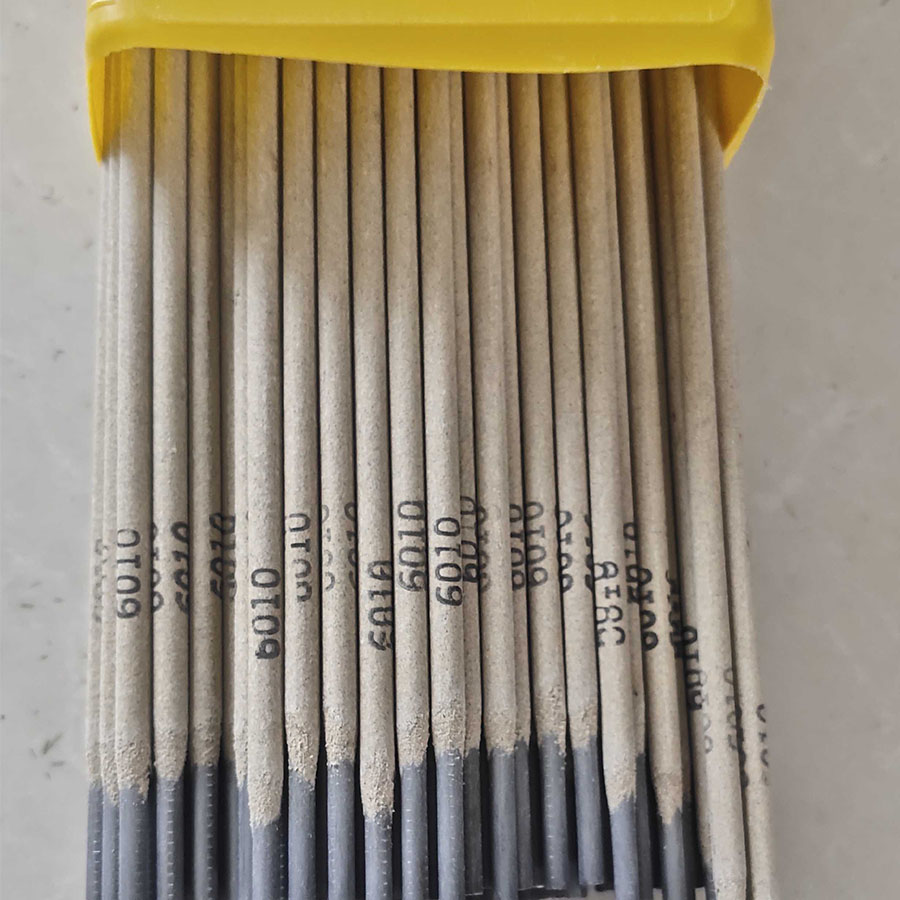

Stick welding, while not the hardest form of welding to learn, can still be difficult at times. Getting an arc to ignite on the first try is absolutely a skill, and not everyone can do it. Starting an arc isn’t the only tricky part of stick welding, so if you’re looking to improve your welding, give these tips and tricks a try.Čitaj više

Stick welding, while not the hardest form of welding to learn, can still be difficult at times. Getting an arc to ignite on the first try is absolutely a skill, and not everyone can do it. Starting an arc isn’t the only tricky part of stick welding, so if you’re looking to improve your welding, give these tips and tricks a try.Čitaj više -

I'm putting together a grant application on advanced FSAW-type piezoelectric resonators coupled to a transmon qubit. To my points: Can you supply 4 inch or 6 inch wafers with thin films of Niobium deposited? >If so, what substrates are possible and what layer thicknesses, and do you have any characterisation of the layer morphology, properties, etc.? Is Niobium on Lithium Niobate possible? >Would it be possible to give me a quote, or an indicative non-binding ballpark price, to assist me with preparation of the grant? Thanks for taking the time to read my message. I'm really excited about this project, so if this is work you are interested in then I'd be very keen to pursue this. In any case, if you can let me know, I'd appreciate it. Best regards, have a good day.Čitaj više

I'm putting together a grant application on advanced FSAW-type piezoelectric resonators coupled to a transmon qubit. To my points: Can you supply 4 inch or 6 inch wafers with thin films of Niobium deposited? >If so, what substrates are possible and what layer thicknesses, and do you have any characterisation of the layer morphology, properties, etc.? Is Niobium on Lithium Niobate possible? >Would it be possible to give me a quote, or an indicative non-binding ballpark price, to assist me with preparation of the grant? Thanks for taking the time to read my message. I'm really excited about this project, so if this is work you are interested in then I'd be very keen to pursue this. In any case, if you can let me know, I'd appreciate it. Best regards, have a good day.Čitaj više -

The word piezoelectricity comes from the Greek word piezein, which means squeeze or press and electron, which means “amber” and is an ancient source of electric charge.The French physicists Jacques and Pierre Curie discovered in 1880 that electric charges could accumulate in certain solid materials in response to an applied mechanical stress.Piezoelectric materials allow conversion of energy from the mechanical domain to the electrical domain and vice versa. They can be used to create various sensors or actuators: applied periodic electrical signal can result in the generation of ultrasonic waves for imaging purposes.Čitaj više

The word piezoelectricity comes from the Greek word piezein, which means squeeze or press and electron, which means “amber” and is an ancient source of electric charge.The French physicists Jacques and Pierre Curie discovered in 1880 that electric charges could accumulate in certain solid materials in response to an applied mechanical stress.Piezoelectric materials allow conversion of energy from the mechanical domain to the electrical domain and vice versa. They can be used to create various sensors or actuators: applied periodic electrical signal can result in the generation of ultrasonic waves for imaging purposes.Čitaj više -

Piezoelectric actuators and other piezoelectric components feature a compact size and low profile, no electromagnetic noise, and a host of other advantages. For this reason, they are increasingly used for auto-focus actuators in cameras and for other applications. Currently, the only practical piezoelectric materials are lead-based materials, and so lead-based materials are widely used in piezoelectric components.Although the lead contained in piezoelectric components is not subject to the RoHS directive and other environmental regulations, it is preferable that a lead-free alternative be developed for the future. Also, lead-based piezoelectric materials cannot be co-fired with Ni, and so currently, high-cost Ag/Pd (palladium) is used for the inner electrodes when stacking. Lead-free piezoelectric materials, on the other hand, enable the possibility of use of low-cost Ni. This paper presents our work in successfully fabricating lead-free multilayer piezoelectric ceramics with Ni inner electrodes.Čitaj više

Piezoelectric actuators and other piezoelectric components feature a compact size and low profile, no electromagnetic noise, and a host of other advantages. For this reason, they are increasingly used for auto-focus actuators in cameras and for other applications. Currently, the only practical piezoelectric materials are lead-based materials, and so lead-based materials are widely used in piezoelectric components.Although the lead contained in piezoelectric components is not subject to the RoHS directive and other environmental regulations, it is preferable that a lead-free alternative be developed for the future. Also, lead-based piezoelectric materials cannot be co-fired with Ni, and so currently, high-cost Ag/Pd (palladium) is used for the inner electrodes when stacking. Lead-free piezoelectric materials, on the other hand, enable the possibility of use of low-cost Ni. This paper presents our work in successfully fabricating lead-free multilayer piezoelectric ceramics with Ni inner electrodes.Čitaj više -

The wrap-around is another common electrode pattern. The wrap-around electrode pattern is typically used when you need to connect more electrical leads to the same surface of the piezo component. This may be relevant if you want to bond the opposite surface of the component against a flat surface. This specific electrode pattern is often used on “thin” piezo components.Please note, the un-electroded band of the electrode pattern must be as wide as the thickness of the component. Therefore, this pattern is not suited for very thick components with very small electrode surface areas.There can be many variations in wrap-around electrode pattern placement and dimensions. Therefore, it is necessary to have a drawing of the desired electrode pattern. Noliac can provide drawings and specifications in order to get full agreement about the design.Čitaj više

The wrap-around is another common electrode pattern. The wrap-around electrode pattern is typically used when you need to connect more electrical leads to the same surface of the piezo component. This may be relevant if you want to bond the opposite surface of the component against a flat surface. This specific electrode pattern is often used on “thin” piezo components.Please note, the un-electroded band of the electrode pattern must be as wide as the thickness of the component. Therefore, this pattern is not suited for very thick components with very small electrode surface areas.There can be many variations in wrap-around electrode pattern placement and dimensions. Therefore, it is necessary to have a drawing of the desired electrode pattern. Noliac can provide drawings and specifications in order to get full agreement about the design.Čitaj više -

Piezoelectric ceramics must go through electrode application and polarization before they can be used properly. Electrode application is a crucial process that determines how piezoelectric ceramics will be assembled with other components. Furthermore, many of our customers’ requirements are closely related to the electrode application of piezoelectric ceramics. Therefore, through the following article, we would like to introduce the knowledge about electrode application of piezoelectric ceramics.Čitaj više

Piezoelectric ceramics must go through electrode application and polarization before they can be used properly. Electrode application is a crucial process that determines how piezoelectric ceramics will be assembled with other components. Furthermore, many of our customers’ requirements are closely related to the electrode application of piezoelectric ceramics. Therefore, through the following article, we would like to introduce the knowledge about electrode application of piezoelectric ceramics.Čitaj više -

Piezoelectricity is exploited in applications such as the production and detection of sound, generation of high voltages, electronic frequency generation, microbalances, to drive an ultrasonic nozzle, and ultrafine focusing of optical assemblies. It is the basis of a number of scientific instrumental techniques with atomic resolution, the scanning probe microscopies such as STM, AFM, MTA and SNOM, as well as everyday uses, such as acting as the ignition source for cigarette lighters, push-start propane barbecues, and quartz watches.A piezoelectric sensor is a device that uses the piezoelectric effect, to measure changes in pressure, acceleration, temperature, strain, or force by converting them to an electrical charge. Although originally discovered in 1880 by French physicists Jacques and Pierre Curie, it was only in the 1950s that manufacturers begin to use the piezoelectric effect in industrial sensing applications. Since then, this measuring principle has been increasingly used, and has become a mature technology with excellent inherent reliability. It has been successfully used in medical, aerospace, nuclear instrumentation, as a tilt sensor in consumer electronics or a pressure sensor in the touch pads of mobile phones.In the automotive industry, piezoelectric elements are used to monitor combustion when developing internal combustion engines. The sensors are either directly mounted into additional holes into the cylinder head or the spark/glow plug is equipped with a built-in miniature piezoelectric sensor.Čitaj više

Piezoelectricity is exploited in applications such as the production and detection of sound, generation of high voltages, electronic frequency generation, microbalances, to drive an ultrasonic nozzle, and ultrafine focusing of optical assemblies. It is the basis of a number of scientific instrumental techniques with atomic resolution, the scanning probe microscopies such as STM, AFM, MTA and SNOM, as well as everyday uses, such as acting as the ignition source for cigarette lighters, push-start propane barbecues, and quartz watches.A piezoelectric sensor is a device that uses the piezoelectric effect, to measure changes in pressure, acceleration, temperature, strain, or force by converting them to an electrical charge. Although originally discovered in 1880 by French physicists Jacques and Pierre Curie, it was only in the 1950s that manufacturers begin to use the piezoelectric effect in industrial sensing applications. Since then, this measuring principle has been increasingly used, and has become a mature technology with excellent inherent reliability. It has been successfully used in medical, aerospace, nuclear instrumentation, as a tilt sensor in consumer electronics or a pressure sensor in the touch pads of mobile phones.In the automotive industry, piezoelectric elements are used to monitor combustion when developing internal combustion engines. The sensors are either directly mounted into additional holes into the cylinder head or the spark/glow plug is equipped with a built-in miniature piezoelectric sensor.Čitaj više -

The world’s energy crisis and environmental pollution are mainly caused by the increase in the use of fossil fuels for energy, which has led scientists to investigate specific cutting-edge devices that can capture the energy present in the immediate environment for subsequent conversion. The predominant form of energy is mechanical energy; it is the most prevalent energy in the environment and can be harvested for conversion into useful, electrical energy. Compared with electromagnetic, electrostatic, magneto strictive, dielectric elastomer and frictional electric transducers, piezoelectric transducers have higher high electrical and mechanical constants, large electromechanical coupling coefficients, high dielectric numbers and low losses and are currently the most dominant method of mechanical energy acquisition. Therefore, the research of piezoelectric transducers has received great attention from the scientific community. This paper reviews the research progress of piezoelectric energy acquisition technology. The main objective of this paper is to compile, discuss and summarize the recent literature on piezoelectric energy harvesting materials and applications. Piezoelectric catalytic materials, piezoelectric supercapacitors (SCs), piezoelectric self-charging devices and piezoelectric electrochemical energy storage are mainly introduced. This review briefly introduces the recent advances in piezoelectric-based catalysts and electrochemical energy storage, concentrating on the attributes of various piezoelectric materials and their uses.Čitaj više

The world’s energy crisis and environmental pollution are mainly caused by the increase in the use of fossil fuels for energy, which has led scientists to investigate specific cutting-edge devices that can capture the energy present in the immediate environment for subsequent conversion. The predominant form of energy is mechanical energy; it is the most prevalent energy in the environment and can be harvested for conversion into useful, electrical energy. Compared with electromagnetic, electrostatic, magneto strictive, dielectric elastomer and frictional electric transducers, piezoelectric transducers have higher high electrical and mechanical constants, large electromechanical coupling coefficients, high dielectric numbers and low losses and are currently the most dominant method of mechanical energy acquisition. Therefore, the research of piezoelectric transducers has received great attention from the scientific community. This paper reviews the research progress of piezoelectric energy acquisition technology. The main objective of this paper is to compile, discuss and summarize the recent literature on piezoelectric energy harvesting materials and applications. Piezoelectric catalytic materials, piezoelectric supercapacitors (SCs), piezoelectric self-charging devices and piezoelectric electrochemical energy storage are mainly introduced. This review briefly introduces the recent advances in piezoelectric-based catalysts and electrochemical energy storage, concentrating on the attributes of various piezoelectric materials and their uses.Čitaj više -

Rapid advances in sensing technologies are leading to the development of integrated wearable electronics for biomedical applications. Piezoelectric materials have great potential for implantable devices because of their self-powered sensing capacities. The soft and highly deformable surfaces of most tissues in the human body, however, restrict the wide use of piezoelectric materials, which feature low stretchability. Flexible piezoelectric polyvinylidene fluoride films that could conformably integrate with human bodies would have advantages in health monitoring. Here, a Kirigami technique with linear cut patterns has been employed to design a stretchable piezoelectric sensor with enhanced piezoelectricity. A parametric Finite Element Analysis study is first performed to investigate its mechanical behaviour, followed by experiments. An inter-segment electrode connection approach is proposed to further enhance the piezoelectric performance of the sensor. The voltage output shows superior performance with 2.6 times improvement compared to conventionally continuous electrodes. Dynamic tests with a range of frequencies and strains are performed to validate the sensor design. With its high performance in large strain measurements, the Kirigami-based sensing system shows promise in stretchable electronics for biomedical devices.Čitaj više

Rapid advances in sensing technologies are leading to the development of integrated wearable electronics for biomedical applications. Piezoelectric materials have great potential for implantable devices because of their self-powered sensing capacities. The soft and highly deformable surfaces of most tissues in the human body, however, restrict the wide use of piezoelectric materials, which feature low stretchability. Flexible piezoelectric polyvinylidene fluoride films that could conformably integrate with human bodies would have advantages in health monitoring. Here, a Kirigami technique with linear cut patterns has been employed to design a stretchable piezoelectric sensor with enhanced piezoelectricity. A parametric Finite Element Analysis study is first performed to investigate its mechanical behaviour, followed by experiments. An inter-segment electrode connection approach is proposed to further enhance the piezoelectric performance of the sensor. The voltage output shows superior performance with 2.6 times improvement compared to conventionally continuous electrodes. Dynamic tests with a range of frequencies and strains are performed to validate the sensor design. With its high performance in large strain measurements, the Kirigami-based sensing system shows promise in stretchable electronics for biomedical devices.Čitaj više -

This post is also available in: Français (French) Italiano (Italian) Deutsch (German)Learn how piezoelectricity produces an electric charge by applying mechanical stress to a piezoelectric material.Piezo what? Piezoelectricity sounds like a lot to take in, but it’s simple to understand. The word piezoelectric originates from the Greek word piezein, which literally means to squeeze or press. Instead of squeezing grapes to make wine, we’re squeezing crystals to make an electric current! Piezoelectricity is in a ton of everyday electronic devices, from quartz watches to speakers and microphones.Čitaj više

This post is also available in: Français (French) Italiano (Italian) Deutsch (German)Learn how piezoelectricity produces an electric charge by applying mechanical stress to a piezoelectric material.Piezo what? Piezoelectricity sounds like a lot to take in, but it’s simple to understand. The word piezoelectric originates from the Greek word piezein, which literally means to squeeze or press. Instead of squeezing grapes to make wine, we’re squeezing crystals to make an electric current! Piezoelectricity is in a ton of everyday electronic devices, from quartz watches to speakers and microphones.Čitaj više -

The low output current density of piezoelectric nanogenerators (PENGs) severely restricts their application for ambient mechanical energy harvest. This has been a key challenge in the development of PENG. Here, to conquer this, based on a piezoelectric material with high piezoelectric coefficient (Sm-PMN-PT), a new design of PENG with a three-dimensional intercalation electrode (IENG) is proposed. By creating many boundary interfaces inside the piezoelectric material, the total amount of surface polarization charges increased, which contributes to an increased current density. The IENG can output a maximum peak short-circuit current of 320 μA, and the corresponding current density 290 μA cm−2 is 1.93 and 1.61 times the record values of PENG and triboelectric nanogenerator (TENG), respectively. It can also charge a 1 μF capacitor from 0 V to 8 V in 21 cycles, and the equivalent surface charge density 1690 μC m−2 is 1.35 times the record value of TENG.Čitaj više

The low output current density of piezoelectric nanogenerators (PENGs) severely restricts their application for ambient mechanical energy harvest. This has been a key challenge in the development of PENG. Here, to conquer this, based on a piezoelectric material with high piezoelectric coefficient (Sm-PMN-PT), a new design of PENG with a three-dimensional intercalation electrode (IENG) is proposed. By creating many boundary interfaces inside the piezoelectric material, the total amount of surface polarization charges increased, which contributes to an increased current density. The IENG can output a maximum peak short-circuit current of 320 μA, and the corresponding current density 290 μA cm−2 is 1.93 and 1.61 times the record values of PENG and triboelectric nanogenerator (TENG), respectively. It can also charge a 1 μF capacitor from 0 V to 8 V in 21 cycles, and the equivalent surface charge density 1690 μC m−2 is 1.35 times the record value of TENG.Čitaj više -

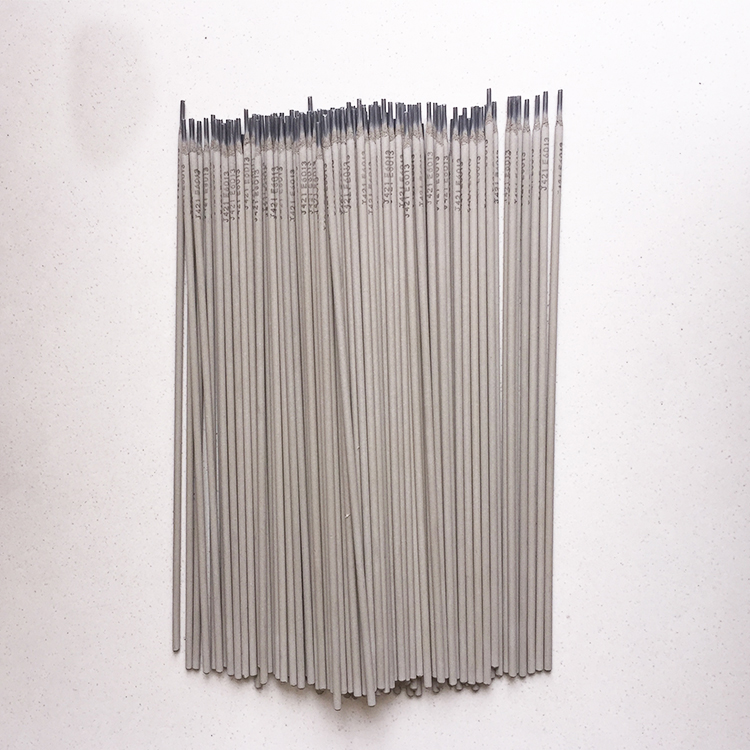

Gas shielded welding wire is an essential component in the welding industry, providing a clean anČitaj više

Gas shielded welding wire is an essential component in the welding industry, providing a clean anČitaj više