china 4043 aluminum welding wire manufacturers

China 4043 Aluminum Welding Wire Manufacturers A Key Player in the Global Market

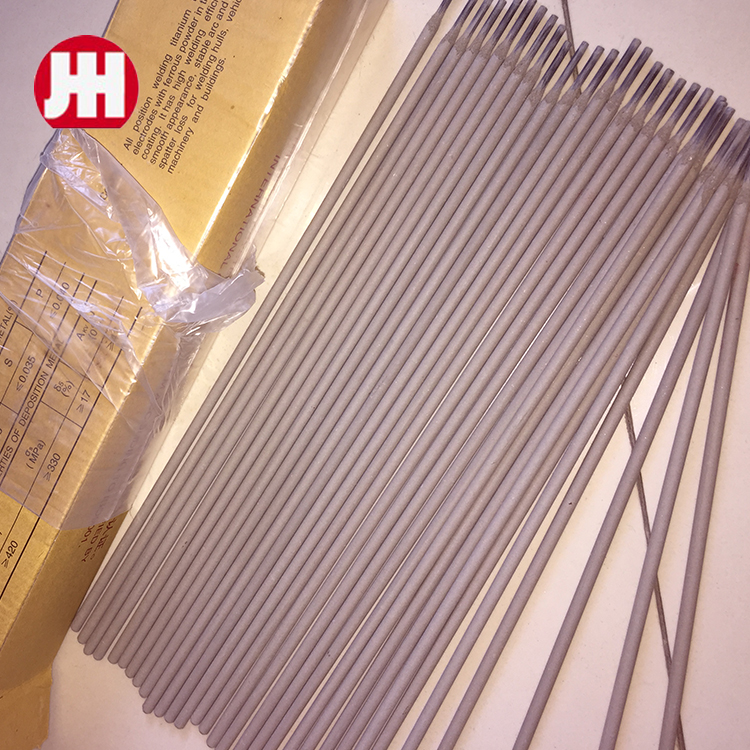

In recent years, the aluminum welding industry has experienced significant growth, with China's 4043 aluminum welding wire manufacturers emerging as a vital component of this evolution. Aluminum welding wires are essential materials widely used in various applications, including automotive, aerospace, and construction industries. Due to the unique properties of aluminum, such as its lightweight and corrosion resistance, these wires have become increasingly popular for fabricating components that require strong and durable joints.

4043 aluminum welding wire is particularly renowned for its versatility, most commonly composed of aluminum-silicon alloy. This composition allows for excellent fluidity, minimizing the occurrence of porosity during the welding process. Additionally, it boasts low shrinkage, which results in reduced cracking and distortion of the welded joint. The high anti-corrosive properties of 4043 wires make them a preferred choice for projects exposed to severe environmental conditions. This wire is suitable for welding various types of aluminum, making it a desirable option for many manufacturers and fabricators.

China, being one of the largest producers of aluminum in the world, has positioned itself as a leading manufacturer of 4043 aluminum welding wires. With an extensive network of suppliers and advanced production techniques, Chinese manufacturers have been able to produce high-quality welding wires that meet international standards. This competitive advantage allows them to cater to both domestic and global markets efficiently.

china 4043 aluminum welding wire manufacturers

Moreover, the rapid advancement in manufacturing technologies and quality control processes in China has further enhanced the quality and reliability of 4043 aluminum welding wires. Many Chinese manufacturers have invested heavily in research and development to innovate and improve the performance of their products. This commitment to quality has led to increased trust among international customers, resulting in a rising demand for Chinese-made welding wires.

The market for aluminum welding wire is not without its challenges. Manufacturers in China face stiff competition from companies in other countries, particularly those in Europe and North America. To maintain their edge in the global market, Chinese manufacturers must focus on innovation and adhere to the highest quality standards. Furthermore, navigating international trade regulations and tariffs is crucial to ensure competitiveness while expanding their footprint abroad.

In addition, sustainability practices are becoming increasingly important. Many manufacturers are adopting environmentally-friendly production methods to reduce their carbon footprint. This trend aligns with global efforts to combat climate change and caters to the growing consumer demand for sustainable products.

In conclusion, Chinese 4043 aluminum welding wire manufacturers are pivotal to the global aluminum welding industry. Their ability to provide high-quality products, combined with competitive pricing and innovative practices, positions them as leaders in this field. As the demand for aluminum solutions continues to rise, these manufacturers are well-prepared to meet evolving market needs while contributing to a sustainable future. The landscape of aluminum welding is undoubtedly changing, and China's role will be crucial in shaping its trajectory.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025