Top Manufacturers of Welding Electrodes in China for Quality Solutions

The Landscape of Electrode Welding Manufacturing in China

China has emerged as a global powerhouse in various manufacturing sectors, and the field of electrode welding is no exception. As industrial applications continue to grow, the demand for high-quality welding electrodes has surged. This article delves into the manufacturing landscape of electrode welding in China, exploring key players, innovations, and market trends.

Electrode welding, commonly employed in construction, automotive, and aerospace industries, is a critical process that ensures the integrity and strength of welds. In this regard, China boasts numerous manufacturers catering to both domestic and international markets. Companies specializing in electrode production have adopted state-of-the-art technologies and rigorous quality control measures to meet the increasing demand for reliable and efficient welding solutions.

The Landscape of Electrode Welding Manufacturing in China

Similarly, Hunan Xianggang Electric Welding Machine Co., Ltd. has carved out a significant niche in the electrode welding market. By leveraging advanced manufacturing techniques and focusing on sustainable practices, Hunan Xianggang has not only fulfilled the needs of domestic clients but has also established a strong presence in export markets. Their dedication to producing high-quality electrodes reflects the broader trend among Chinese manufacturers to emphasize quality over mere quantity.

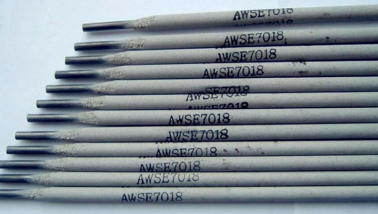

china electrodo soldadura manufacturers

The rapid growth of the welding machine market has also influenced electrode manufacturing. The integration of automation and smart technology in welding processes has necessitated the production of electrodes that can withstand demanding conditions. Chinese manufacturers are investing heavily in research to develop electrodes that feature superior performance, such as enhanced arc stability, reduced spatter, and improved mechanical properties.

Moreover, China's manufacturing capabilities extend beyond just producing electrodes; the nation is increasingly recognized for its ability to innovate. Many manufacturers are prioritizing eco-friendly materials and processes, responding to global trends towards sustainability. This shift not only helps in reducing the carbon footprint but also positions Chinese manufacturers favorably in the international market where environmental regulations are becoming more stringent.

As the construction and automotive industries continue to expand, particularly with the rise of infrastructure projects and electric vehicle production, the demand for high-quality welding electrodes is projected to grow further. Chinese manufacturers are poised to meet this demand by continuing to enhance their production techniques and investing in new technologies, ensuring that they remain competitive on a global scale.

In conclusion, the electrode welding manufacturing industry in China is characterized by a blend of traditional craftsmanship and modern technological innovations. With a strong commitment to quality, sustainability, and research and development, Chinese manufacturers are not only catering to their domestic markets but are also setting the stage for a significant presence in global supply chains. As the industry evolves, China’s role as a leading player in electrode welding manufacturing will likely continue to solidify, shaping the future of welding technology worldwide.

-

High Quality E71T-11 Welding Wire from China – Flux Cored, Easy to UseNewsJul.28,2025

-

High-Quality SG2 Welding Wire for Superior PerformanceNewsJul.27,2025

-

E6011 Welding Rod for Arc Welding – High Performance & VersatilityNewsJul.26,2025

-

Welding Rod 2.0 mm for Structural Welding - High Strength & PrecisionNewsJul.25,2025

-

Factory Supply Cast Iron Welding Rods AWS ENi-CI High StrengthNewsJul.24,2025

-

Premium 7018 Welding Rods Electrodes for Strong WeldsNewsJul.23,2025