china er316l welding rod factories

Exploring the Landscape of China ER316L Welding Rod Factories

China has established itself as a global powerhouse in manufacturing across various sectors, and the welding industry is no exception. Among the many products produced, ER316L welding rods stand out due to their specific applications and robust properties. Widely used in stainless steel welding, ER316L rods are renowned for their excellent corrosion resistance and superior weldability, making them ideal for industries such as food processing, chemical, and marine engineering. This article delves into the landscape of ER316L welding rod factories in China, highlighting their significance, manufacturing processes, and the contribution to global markets.

Understanding ER316L Welding Rods

ER316L is a low-carbon version of the standard ER316 welding rod, designed to minimize carbide precipitation during welding processes. This characteristic is particularly crucial when working with stainless steel components exposed to high temperatures. The primary alloying elements in ER316L rods include chromium, nickel, and molybdenum, which collectively enhance resistance to pitting and crevice corrosion. As industries increasingly adopt stainless steel products, the demand for ER316L welding rods has surged, prompting local manufacturers in China to enhance their production capabilities.

The Role of Chinese Factories in Production

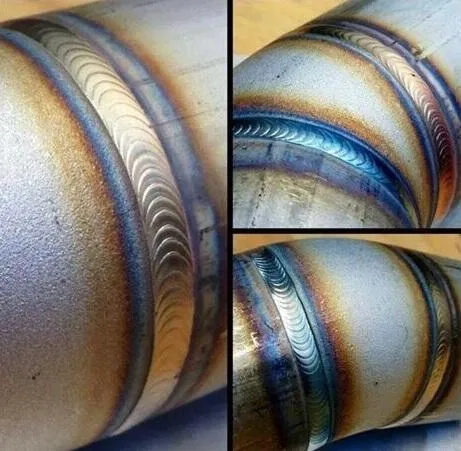

China's extensive industrial ecosystem provides a fertile ground for the production of ER316L welding rods. Numerous factories specialize in the manufacturing of these rods, benefiting from a combination of advanced technology, skilled labor, and abundant raw materials. The production process typically begins with the preparation of the alloying materials. Stainless steel wires are drawn to the appropriate diameter, followed by a series of treatments to ensure desired mechanical properties.

Chinese factories often employ state-of-the-art machinery and automated processes, enabling them to produce high-quality ER316L rods at competitive prices. Moreover, stringent quality control measures are implemented throughout the production stages, ensuring that the rods meet international standards and specifications. This commitment to quality has earned Chinese manufacturers a strong reputation in the global market.

Export Dynamics and Global Reach

china er316l welding rod factories

The demand for ER316L welding rods transcends national borders, positioning Chinese manufacturers as key players in the international welding market. Countries around the world rely on China for these essential welding materials, attracted by the combination of quality and affordability. In recent years, the government has actively promoted initiatives to strengthen export capabilities, facilitating smoother logistics and fostering international partnerships.

As a result, Chinese factories have established expansive distribution networks, reaching far beyond regional markets. They often participate in international trade shows, showcasing their products and innovations, thus enhancing their visibility and relationships with potential clients worldwide. This globalization of the Chinese welding rod industry reflects the country's strategic positioning as a manufacturing leader.

Challenges and Future Prospects

Despite the promising landscape, ER316L welding rod manufacturers in China face several challenges. These include fluctuations in raw material prices, environmental regulations, and increasing competition from other manufacturing nations. To maintain their competitive edge, Chinese factories are investing in research and development, focusing on improving production efficiency and product innovation.

Moreover, as global markets increasingly emphasize sustainability, manufacturers are exploring eco-friendly practices in their operations. This includes reducing waste and energy consumption during the production process and considering alternative materials that minimize environmental impact. The shift towards sustainable manufacturing is not only essential for compliance but also appeals to a growing base of environmentally-conscious consumers.

Conclusion

In conclusion, China’s ER316L welding rod factories play an indispensable role in the global welding market, characterized by a rich landscape of innovation, quality production, and responsive supply chains. As they navigate challenges and embrace sustainability, these factories are poised to continue their trajectory of growth and prominence. With the rising demand for high-quality welding materials, China's role in supplying ER316L welding rods will remain critical in meeting the needs of diverse industries worldwide. The ongoing evolution of these manufacturers will undoubtedly shape the future of welding technologies and practices, reinforcing China's status as a global manufacturing leader.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025