china flux cored mig wire

Understanding China Flux Cored MIG Wire A Comprehensive Overview

In the realm of welding, choosing the right materials can significantly impact the quality and efficiency of the process. One of the prominent options is flux cored MIG wire, particularly those produced in China, which have gained recognition for their affordability and performance.

Understanding China Flux Cored MIG Wire A Comprehensive Overview

One of the primary advantages of China-made flux cored MIG wire is its cost-effectiveness. With a streamlined manufacturing process and lower labor costs, these products often come at a price point that appeals to welders and contractors looking to minimize expenses. However, it is crucial to balance cost with quality. Many Chinese manufacturers have invested in modern technology and rigorous quality control processes to ensure their products meet international standards.

china flux cored mig wire

Moreover, the performance of flux cored MIG wire is highly regarded in various sectors, from automotive to construction. The flux core allows for deeper penetration compared to solid wires, which is beneficial for thicker materials. This characteristic not only enhances joint strength but also reduces the likelihood of defects, such as porosity. Furthermore, the slag produced during welding can often be easily removed, resulting in a cleaner finish.

Nevertheless, not all flux cored MIG wires are created equal. Welders must consider factors like the specific type of flux cored wire needed for their projects—whether it requires all-position capability, high tensile strength, or low-temperature toughness. Choosing the right wire involves assessing the base materials, the intended application, and the desired mechanical properties of the weld.

In conclusion, China produces a wide range of flux cored MIG wires that cater to various welding needs, offering a balance of performance and cost. As the demand for efficient and reliable welding solutions continues to grow, the importance of understanding and selecting the appropriate flux cored wire cannot be overstated. Proper research and consideration will ensure that welders can achieve optimal results, making informed choices that enhance the overall quality of their work. With the right materials, the possibilities for successful welding projects are endless.

-

Premium AC Stainless Steel Welding Rods - Durable & Corrosion-ResistantNewsAug.05,2025

-

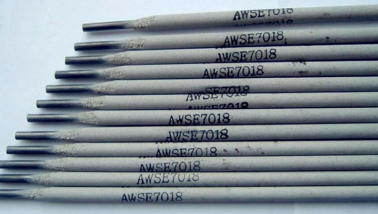

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025