Supplier of 3.2mm Welding Stick Electrodes in China for Quality Welding Solutions

Quality Welding Stick Electrodes A Look at Leading Suppliers in China

When it comes to welding, the choice of electrode is critical to ensuring strong, reliable welds. For both amateur and professional welders, the welding stick, often referred to as a welding electrode, plays a vital role in determining the quality of the finished product. In recent years, China has emerged as a key player in the global welding supply market, effectively catering to the increasing demand for high-quality welding stick electrodes.

The Importance of Choosing the Right Electrode

Welding electrodes come in various types, compatible with different welding processes such as Shielded Metal Arc Welding (SMAW), Gas Metal Arc Welding (GMAW), and Flux-Cored Arc Welding (FCAW). The core composition and coating of the electrode can affect the mechanical and chemical properties of the weld. Therefore, selecting the right supplier, especially in a polycentric market like China, is paramount for obtaining the best welding electrodes suited to specific applications.

Chinese Suppliers Leading the Market

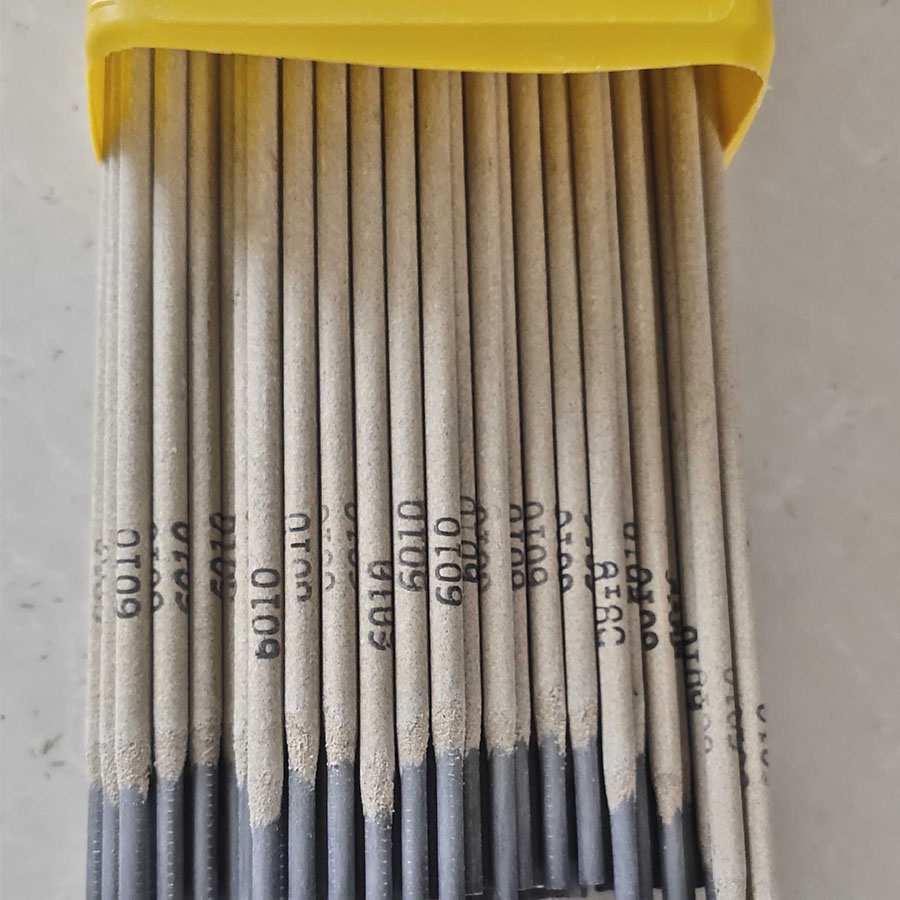

Chinese suppliers have gained a reputation for providing a wide range of welding stick electrodes, including popular sizes like 3.2 mm. This specific size is favored for its versatility in multiple welding applications, making it a staple in workshops and factories alike. Suppliers in China utilize advanced manufacturing technologies and stringent quality control measures to ensure their products meet international standards.

Several renowned Chinese manufacturers specialize in producing high-quality electrodes. Companies such as Jinan Jinchang Welding Materials Co., Ltd., and Jining Xunda Pipe Fittings Co., Ltd., have established themselves as reputable sources. These suppliers focus on innovation and quality control, offering a variety of products including low hydrogen electrodes, stainless steel electrodes, and alloy electrodes. Their commitment to excellence ensures that customers receive electrodes that deliver reliable performance and durability.

Factors to Consider When Choosing a Supplier

china welding stick electrode 3.2 supplier

When looking for a welding stick electrode supplier in China, several factors should be taken into account

1. Quality Assurance It is essential to verify that the supplier adheres to international quality standards, such as ISO certification. A reliable supplier will provide information about their quality assurance processes and testing methods.

2. Product Range Depending on specific welding requirements, it’s important to select a supplier that offers a broad range of electrode types and sizes. This flexibility can be a significant advantage, especially for businesses dealing with various materials and applications.

3. Price Competitiveness While price should not be the sole consideration, it is crucial to compare pricing between different suppliers. Finding a cost-effective supplier that doesn’t compromise on quality can significantly influence overall project budgets.

4. Customer Support An efficient supplier should offer excellent customer service, including timely responses to inquiries and reliable support for any issues that may arise post-purchase.

The Future of Welding Electrodes in China

As industry demands evolve, Chinese suppliers are continually looking to improve their product offerings. The introduction of smart manufacturing techniques and eco-friendly practices in electrode production is becoming more prevalent. These advancements not only enhance the quality of the electrodes but also address sustainability concerns, making the production process more environmentally friendly.

In conclusion, the Chinese market for welding stick electrodes, particularly the 3.2 mm size, is robust and filled with competitive suppliers. By focusing on quality, variety, and customer service, these suppliers are positioned to meet both current and future welding needs. For welders around the globe, the right sourcing decision can lead to improved results in their projects, driving home the importance of choosing a reliable supplier in this ever-evolving industry.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025