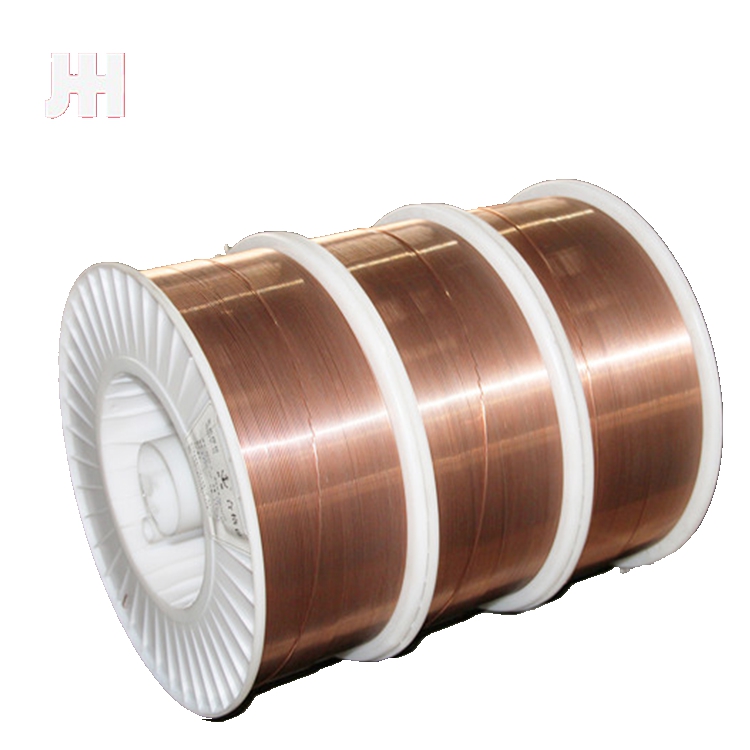

gasless mig wire manufacturers

The Rise of Gasless MIG Wire Manufacturers A New Era in Welding

In the ever-evolving world of welding, the quest for efficiency, quality, and innovation continues to shape the industry. One of the most significant advancements in recent years has been the development of gasless MIG welding, especially through the proliferation of gasless MIG wire manufacturers. These manufacturers are transforming the traditional welding landscape, providing welders with more versatile and convenient solutions.

Understanding Gasless MIG Welding

Gasless MIG welding, also known as flux-cored arc welding (FCAW), eliminates the need for a shielding gas during the welding process. Instead, the wire itself is coated with a flux that generates a shielding gas when it melts. This innovation is especially beneficial for outdoor applications or in windy environments where traditional MIG welding would be less effective.

The use of gasless MIG wire has several advantages. It not only simplifies the setup process by removing the requirement for gas tanks and regulators but also makes it more portable. Welders can easily transport their equipment without worrying about securing or transporting gas cylinders, making it ideal for on-site jobs.

The Role of Gasless MIG Wire Manufacturers

With the increasing demand for gasless solutions, manufacturers specializing in gasless MIG wires have emerged as key players in the welding industry. These companies invest in research and development to create high-quality welding wires that meet industry standards while offering excellent performance across various applications.

One of the primary focuses of these manufacturers is to ensure that their gasless MIG wires deliver strong, clean welds with minimal spatter. By perfecting the formulation of the flux material and the wire composition, they are capable of producing wires that work effectively on different metals and in diverse conditions. This versatility is a significant factor in the growing popularity of gasless MIG welding among professionals and hobbyists alike.

The Benefits of Choosing Gasless MIG Wires

gasless mig wire manufacturers

1. Versatility Gasless MIG wires are suitable for a wide range of materials, including carbon steel, stainless steel, and aluminum. This adaptability is crucial for welders who work on various projects and need reliable performance across different substrates.

2. Ease of Use For beginners and experienced welders, gasless MIG welding is easier to master. The absence of external gas means there's less setup time and fewer variables to manage, allowing for a more straightforward welding experience.

3. Cost-Effective While the initial investment in a MIG welding machine may be substantial, opting for gasless MIG wire eliminates ongoing costs associated with gas supplies and refills. This aspect makes it a cost-effective option for both small businesses and individual welders.

4. Outdoor Capability As mentioned earlier, gasless MIG welding excels in outdoor environments. It remains effective irrespective of wind conditions, making it the preferred choice for construction sites or outdoor repairs.

Challenges and Considerations

Despite the many advantages, gasless MIG wire is not without its challenges. Welders may notice a slightly different bead profile compared to traditional MIG welding, and there can be more slag produced, which requires additional cleanup. Additionally, the learning curve for adjusting settings such as wire speed and voltage may be steeper for those accustomed to conventional MIG welding.

Conclusion Embracing the Future of Welding

The rise of gasless MIG wire manufacturers embodies the ongoing innovation that characterizes the welding industry. By providing advanced solutions that meet the needs of today’s welders, these manufacturers are not only enhancing performance but are also paving the way for greater flexibility and accessibility in welding practices.

As the market continues to evolve, the collaboration between manufacturers and users will likely lead to further advancements. For welders looking to enhance their skill set and elevate their projects, embracing gasless MIG welding could be the key to unlocking new possibilities in this dynamic field. As the technology develops and becomes more widespread, the future looks bright for gasless MIG wire and its manufacturers, promising a new era of efficiency and productivity in welding.

-

Premium AC Stainless Steel Welding Rods - Durable & Corrosion-ResistantNewsAug.05,2025

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025