Top Suppliers for Stick Electrode Welding Products and Equipment

Stick Electrode Welding Suppliers An Overview

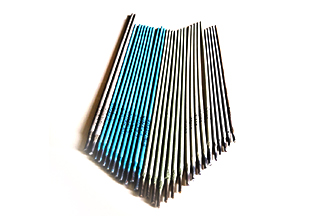

Stick electrode welding, also known as Shielded Metal Arc Welding (SMAW), is a widely used welding process in various industries. This technique employs a consumable electrode coated in flux to join metal pieces. The arc produced between the electrode and the workpiece melts both the electrode and the base metal, creating a strong weld. For manufacturers, construction companies, and DIY enthusiasts alike, sourcing high-quality stick electrodes is crucial for ensuring welding efficiency and durability. This article explores the importance of stick electrode welding suppliers and how to choose the right one for your needs.

Importance of Quality Suppliers

When it comes to stick electrode welding, the quality of the electrodes can significantly affect the outcome of the weld. Poor-quality electrodes can lead to weak joints, slag inclusions, and other defects that compromise the integrity of the work. Therefore, partnering with reliable suppliers is essential. Quality suppliers not only offer products that meet industry standards but also provide valuable support and guidance regarding the type of electrodes suitable for specific applications.

Factors to Consider When Choosing a Supplier

1. Product Range A reputable supplier should offer a comprehensive selection of stick electrodes suitable for various welding applications. This includes different sizes, coatings, and materials that cater to diverse welding needs, from general construction to specialized industries such as pipe welding or structural fabrication.

2. Quality Assurance It is essential to choose suppliers that adhere to industry standards and certifications, such as ISO 9001. This ensures that the products have undergone rigorous testing and meet quality benchmarks. Look for suppliers that provide documentation regarding the welding electrodes they supply, including chemical composition and mechanical properties.

stick electrode welding suppliers

3. Technical Support Good suppliers offer technical support and advice on electrode selection and welding techniques. They should be willing to consult on the best practices and equipment necessary for your specific welding projects. This level of support can save time and reduce errors, enhancing overall productivity.

4. Pricing While it’s important not to compromise quality for cost, competitive pricing is still a significant factor to consider. Evaluate multiple suppliers to ensure you’re getting the best value for your investment. Keep an eye out for bulk purchasing options, as many suppliers offer discounts for larger orders.

5. Delivery and Availability Timely delivery is crucial, especially for large projects with tight deadlines. Suppliers should have a reliable logistics system in place to ensure that the products are delivered on time. Additionally, it’s beneficial to find suppliers that maintain a steady inventory of popular products, reducing wait times for replenishment.

6. Customer Reviews and Reputation Researching customer feedback on suppliers can provide insights into their reliability and service quality. Look for testimonials and online reviews that reflect other customers' experiences. A supplier with a positive reputation can often be a safer choice.

Conclusion

In the world of welding, the choice of stick electrode welding suppliers can significantly impact both the quality of the welds produced and the efficiency of the workflow. By considering factors such as product range, quality assurance, technical support, pricing, delivery, and customer reputation, businesses and individuals can make informed decisions that meet their specific needs. Investing time in finding the right supplier will ultimately lead to better welding outcomes and contribute to the long-term success of projects in various industries. Whether you are a seasoned professional or a beginner in the field of welding, the selection of the right stick electrode supplier is a critical step toward achieving your welding goals.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025