velj . 15, 2025 22:14

Back to list

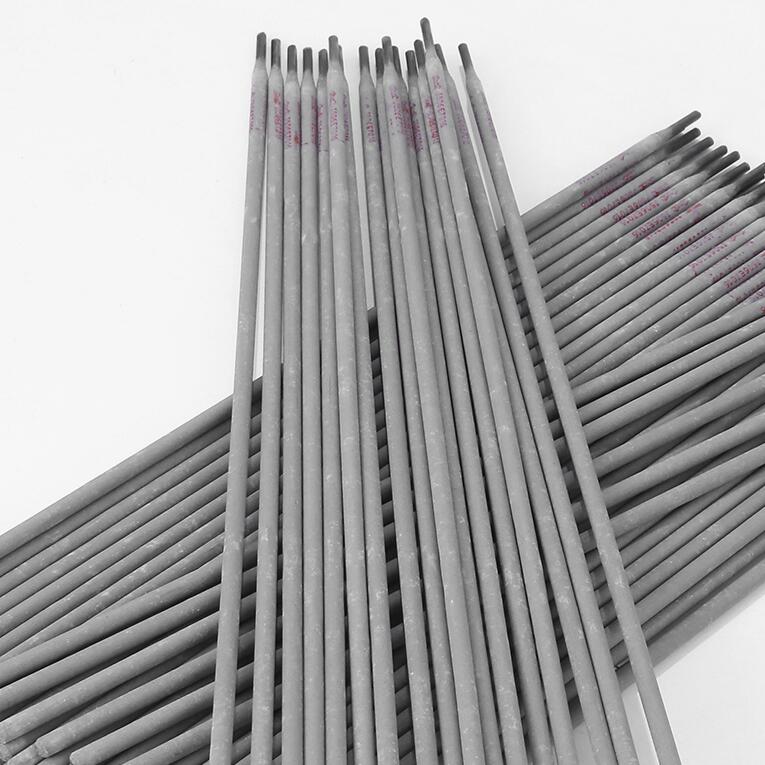

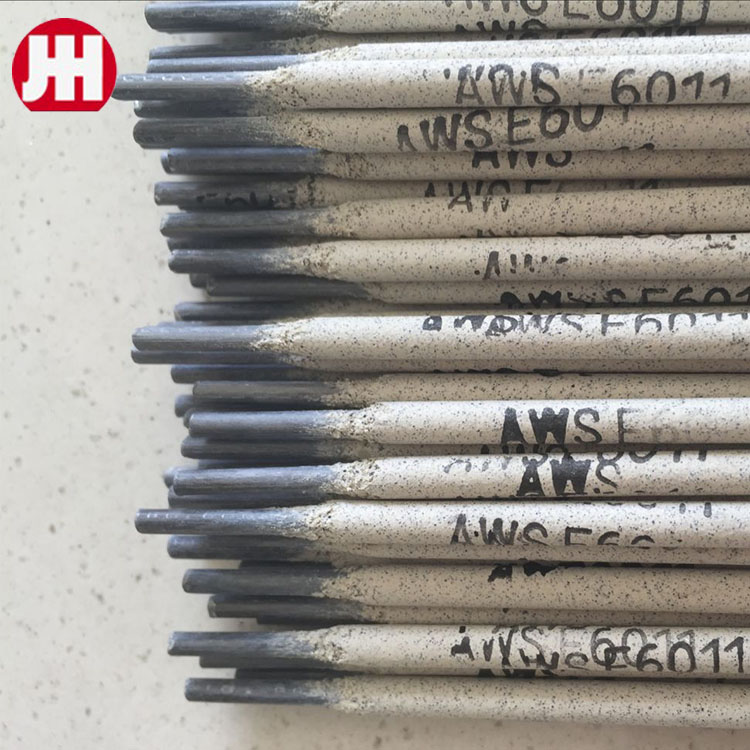

carbon sticks for welding

Wholesale electrode welding sticks are a cornerstone in the industrial and DIY sectors, celebrated for their versatility and efficacy in various welding applications. Their significance cannot be overstated, as they play a critical role in industries ranging from automotive to construction. Let's delve into the intricate details of welding electrodes, their applications, and why they are indispensable in the world of metalwork.

Expertise in welding also highlights the role of proper handling and storage of electrodes, a factor often overlooked but crucial for maintaining their effectiveness. Moisture can compromise the flux coating, leading to weld defects. Thus, implementing best practices for storage, such as using electrode ovens or rod guards to keep them dry, is imperative. Authoritativeness in retailing wholesale electrode welding sticks translates into a comprehensive understanding of customer needs and providing tailored solutions. A retailer with an adept grasp of the products can recommend the ideal electrode, considering factors specific to the customer’s projects and goals. This bespoke approach not only builds trust but also establishes the retailer as a leader in the market. Trustworthiness in this realm is built through transparency and excellent customer service. Offering detailed information about product specifications, accreditation, and compliance with international standards reassures customers of the product’s quality. Moreover, reliable delivery schedules and responsive support fortify customer relationships, essential for long-term business success. In conclusion, wholesale electrode welding sticks epitomize a perfect blend of science and craft, fundamental to the welding industry. Their selection and use demand a nuanced understanding, backed by experience, expertise, authoritativeness, and trustworthiness. Mastery in this domain benefits both the retailer and the end-user, paving the way for successful, safe, and efficient welding applications. As technology evolves, the innovation and adaptability of welding electrodes continue to meet the ever-changing demands of modern industry, affirming their vital role in metal fabrication and repair.

Expertise in welding also highlights the role of proper handling and storage of electrodes, a factor often overlooked but crucial for maintaining their effectiveness. Moisture can compromise the flux coating, leading to weld defects. Thus, implementing best practices for storage, such as using electrode ovens or rod guards to keep them dry, is imperative. Authoritativeness in retailing wholesale electrode welding sticks translates into a comprehensive understanding of customer needs and providing tailored solutions. A retailer with an adept grasp of the products can recommend the ideal electrode, considering factors specific to the customer’s projects and goals. This bespoke approach not only builds trust but also establishes the retailer as a leader in the market. Trustworthiness in this realm is built through transparency and excellent customer service. Offering detailed information about product specifications, accreditation, and compliance with international standards reassures customers of the product’s quality. Moreover, reliable delivery schedules and responsive support fortify customer relationships, essential for long-term business success. In conclusion, wholesale electrode welding sticks epitomize a perfect blend of science and craft, fundamental to the welding industry. Their selection and use demand a nuanced understanding, backed by experience, expertise, authoritativeness, and trustworthiness. Mastery in this domain benefits both the retailer and the end-user, paving the way for successful, safe, and efficient welding applications. As technology evolves, the innovation and adaptability of welding electrodes continue to meet the ever-changing demands of modern industry, affirming their vital role in metal fabrication and repair.

Previous:

Latest news

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025