china 2.5mm welding rod factory

Understanding the 2.5mm Welding Rod Production in China

In the world of manufacturing and construction, welding plays a crucial role in metal joining and fabrication, making welding rods essential components of many industries. Among the various types of welding rods, the 2.5mm welding rod stands out due to its versatility, ease of use, and efficiency in welding applications. In China, one can find a thriving market and numerous factories dedicated to the production of these welding rods, catering to both domestic and international demands.

The Significance of 2.5mm Welding Rods

The 2.5mm welding rod is commonly used in various welding processes including shielded metal arc welding (SMAW), gas tungsten arc welding (GTAW), and many others. Its diameter makes it suitable for a range of tasks, from light fabrication work to heavier industrial applications. The rods are typically made from a combination of materials, which provide them with the strength and durability necessary for high-quality welds.

Producers focus on developing rods that can easily penetrate and fuse different types of metals, including mild steel, stainless steel, and alloy steels. The choice of this diameter rod is often preferred for its balance of heat input and metal deposition, allowing for precise and effective welds without excessive heat distortion.

The Production Process

The manufacturing process of 2.5mm welding rods in China involves several key steps, ensuring that each rod meets stringent quality standards. First, raw materials, including iron powder, alloys, and coatings, are sourced. These materials must be of high quality to guarantee the durability and performance of the welding rods.

Next, the raw materials go through a meticulous blending process where they are mixed in precise ratios. Once the mixture is prepared, it undergoes a shaping process, where it is extruded into the desired diameter of 2.5mm. Following this, the rods are cut to the appropriate lengths and prepared for the next phase, which involves coating. The coating process is vital, as it provides the necessary flux that aids in shielding the weld from atmospheric contamination during the welding process.

china 2.5mm welding rod factory

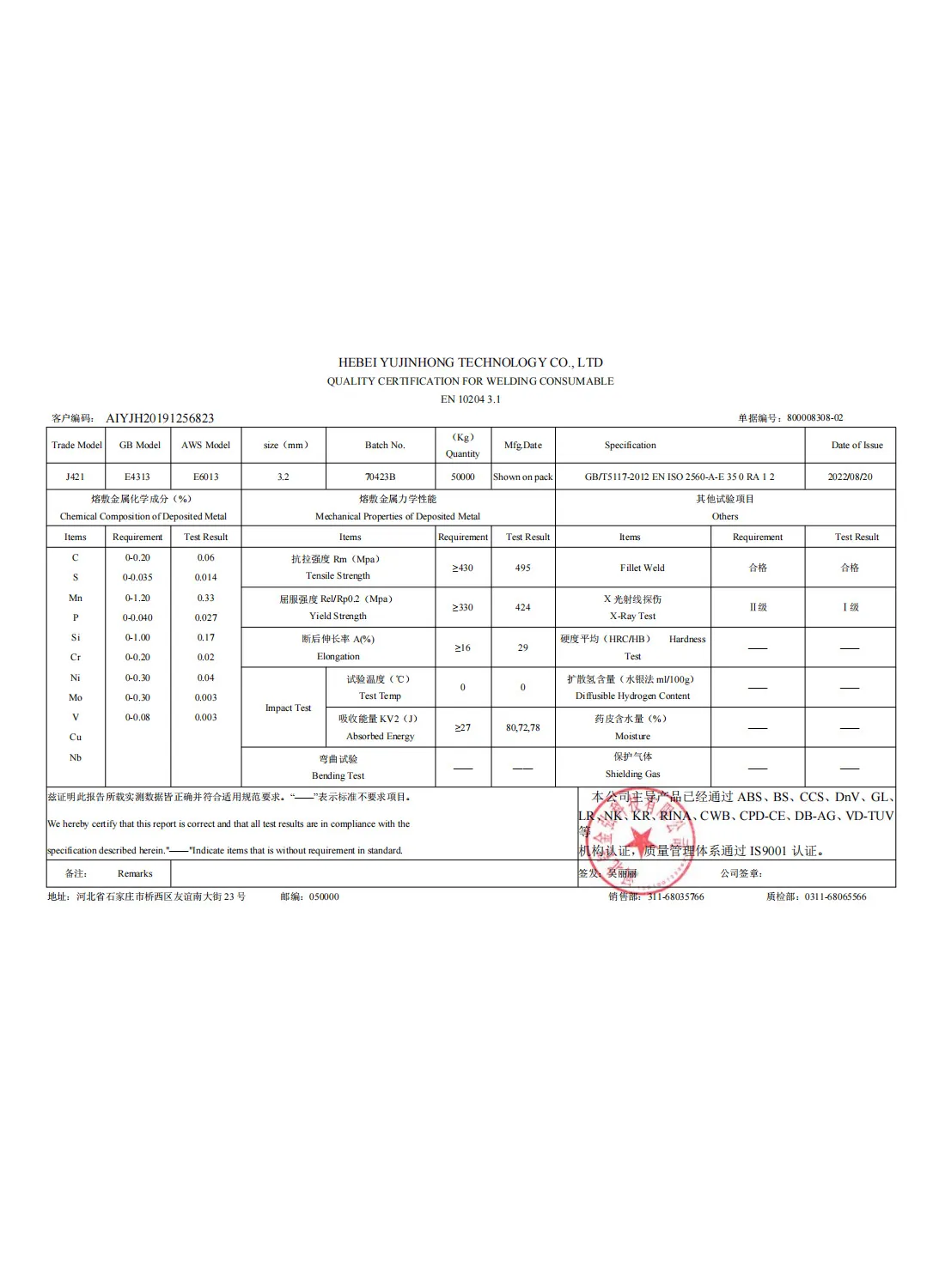

After coating, the rods undergo rigorous quality control checks. These inspections evaluate the physical properties of the rods, ensuring they meet specifications related to tensile strength, elongation, and chemical composition. Manufacturers in China invest in advanced testing technologies to guarantee that their welding rods are reliable and suitable for various applications.

The Role of Technology and Innovation

China's welding rod factories are increasingly adopting modern technologies to enhance production efficiency and product quality. Automation in the manufacturing process has minimized human error while maximizing production outputs. Additionally, factories are investing in research and development to innovate new rod formulations that can cater to specialized welding needs, such as higher strength requirements or enhanced corrosion resistance.

Furthermore, due to China’s robust supply chain and infrastructure, many factories can swiftly adapt to market demands. This responsiveness ensures that businesses, whether large or small, can access the welding rods they need promptly, contributing to a more dynamic industrial environment.

Market Outlook

The global market for welding rods, particularly the 2.5mm variants, is poised for steady growth. As industries such as construction, automotive, and shipbuilding expand, the demand for high-quality welding materials will continue to rise. China, being one of the largest manufacturers of welding consumables, will likely play a pivotal role in meeting this rising demand.

In conclusion, the production of 2.5mm welding rods in China exemplifies the country's industrial capabilities, combining quality, efficiency, and innovation. The welding industry's future, supported by these manufacturing advancements, remains bright as it continues to evolve and adapt to the changing needs of various sectors around the globe.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025