China Suppliers for CO2 Welding Wire and Related Products in the Industry

An Overview of China CO2 Welding Wire Suppliers

The welding industry has been a critical component of various manufacturing and construction sectors globally. Among the various types of welding processes, CO2 welding, or gas shielded arc welding, is particularly noteworthy due to its efficiency and versatility. As the manufacturing landscape continues to evolve, China has emerged as a significant player in the production of CO2 welding wires. This article explores the key aspects of CO2 welding wire suppliers in China, their offerings, and their importance in the global market.

The Relevance of CO2 Welding Wire

CO2 welding wires are essential consumables used in the process of gas metal arc welding (GMAW). This process offers several advantages, including high welding speed, good penetration, and minimal cleanup due to reduced spatter. These wires are primarily made from steel and are designed to be used with carbon dioxide as a shielding gas. This enables effective protection of the weld pool from atmospheric contamination, thereby producing cleaner and stronger welds.

With the rise of industrial activities and infrastructure development, the demand for CO2 welding wires has significantly increased. Industries such as automotive, construction, shipbuilding, and manufacturing heavily rely on these wires for their welding needs. Thus, suppliers who can provide high-quality CO2 welding wires play a crucial role in supporting these sectors.

China as a Leading Supplier

China has positioned itself as one of the largest producers and exporters of CO2 welding wires globally. The country is home to numerous manufacturers that specialize in steel and welding materials. These suppliers benefit from a robust industrial base and a well-established supply chain, enabling them to produce welding wires at competitive prices.

The quality of CO2 welding wires from China is also notable. Many manufacturers adhere to international standards, ensuring that their products meet the requirements of both domestic and foreign markets. Certifications such as ISO9001 and others are commonly seen among suppliers, enhancing their credibility and trustworthiness. These manufacturers utilize advanced production techniques and technologies, which allow them to maintain consistent quality and meet the varying demands of different industries.

Product Range and Specialization

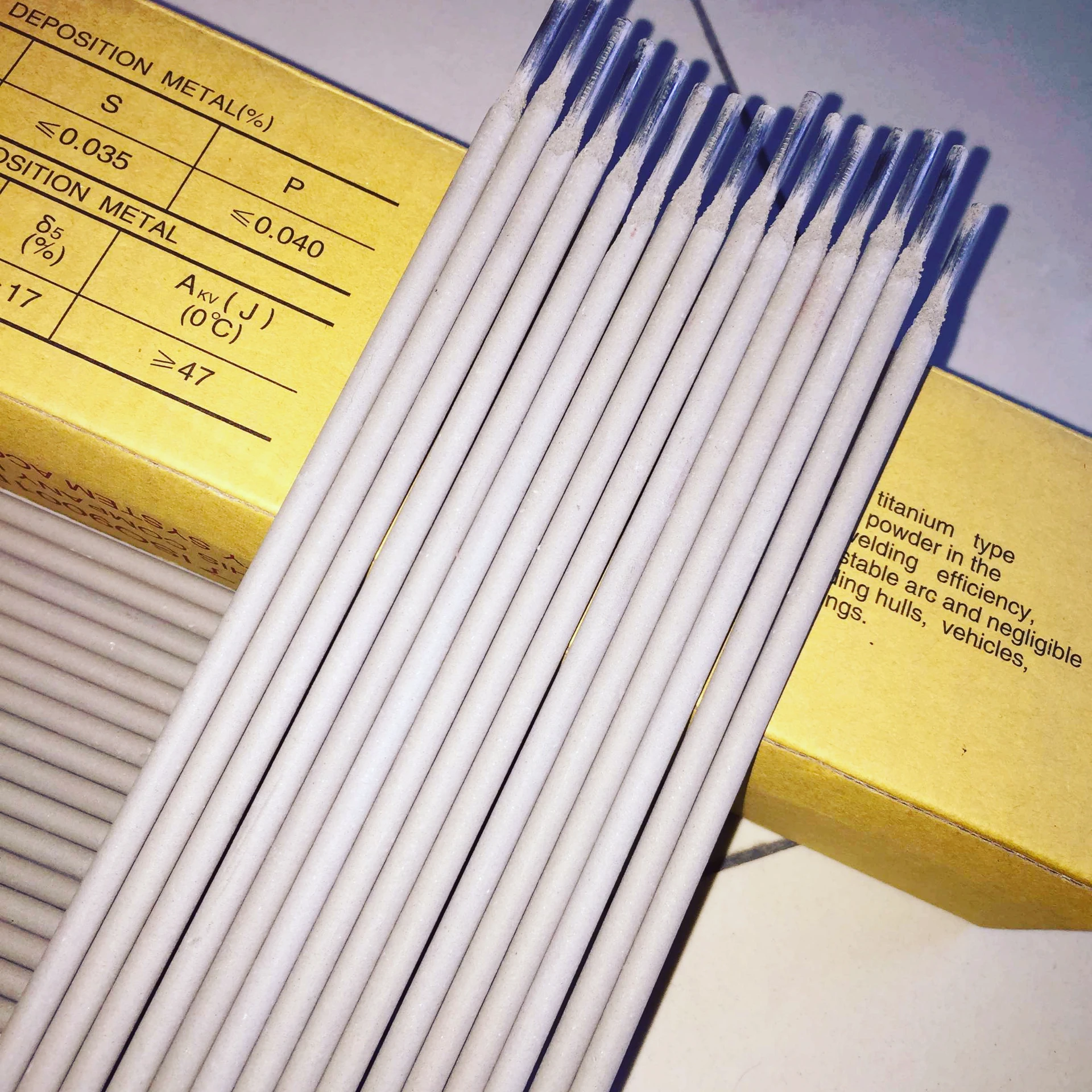

china co2 welding wire suppliers

Chinese suppliers offer a diverse range of CO2 welding wires, catering to various applications and specifications. These include

1. Solid Wire Known for its excellent welding performance, solid wire is suitable for a wide range of applications, from thin sheets to thicker materials. 2. Flux-Cored Wire This type provides exceptional resistance to porosity and is ideal for welding in outdoor environments.

3. Alloyed Wire Special alloys are often used to enhance the properties of the weld, such as increased strength or corrosion resistance.

4. Customized Solutions Many suppliers are willing to work closely with clients to develop customized welding wires that meet specific requirements or standards.

Market Challenges and Opportunities

While the market for CO2 welding wires in China is thriving, it does face several challenges. International competition is fierce, particularly from countries with established welding industries. Additionally, fluctuating raw material prices can impact production costs. To mitigate these challenges, Chinese suppliers are increasingly focusing on innovation, product development, and expanding their global presence.

Furthermore, sustainability has become a focal point in manufacturing. As a response, many suppliers are investing in eco-friendly practices and developing green welding materials that minimize environmental impact. This trend not only aligns with global sustainability goals but also opens new avenues for business.

Conclusion

In summary, China’s role as a leading supplier of CO2 welding wires is significant in today’s global market. With a wide range of products, adherence to quality standards, and competitive pricing, Chinese manufacturers are well-positioned to meet the growing demand for welding supplies. As the industry evolves, ongoing innovation and a commitment to sustainability will be key factors that enhance their competitiveness and appeal in both domestic and international markets. Stakeholders in various sectors must consider these suppliers as viable partners in their welding needs, delivering the quality and reliability necessary for successful operations.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025