china er70s welding wire supplier

China ER70S Welding Wire Supplier A Comprehensive Overview

In the world of welding, the choice of materials plays a pivotal role in determining the quality and integrity of the final product. Among various welding consumables, ER70S welding wire stands out as a popular choice, particularly in the field of MIG (Metal Inert Gas) welding. This article explores the significance of ER70S welding wire, especially focusing on suppliers based in China, which has become a prominent hub for welding materials.

Understanding ER70S Welding Wire

ER70S welding wire is classified as a low-carbon steel filler metal. The designation “ER” stands for “electrode rod,” while “70” indicates the minimum tensile strength in thousands of psi — in this case, 70,000 psi. The “S” signifies that the wire is solid, as opposed to flux-cored or other variations. This welding wire is widely used for welding copper-coated, mild, and low-alloy steels, making it versatile in various industries, including automotive, shipbuilding, and construction.

One of the key advantages of ER70S welding wire is its excellent arc stability, smooth bead appearance, and minimal spatter. It can be used in various welding positions and is compatible with numerous shielding gases, such as argon, CO2, or a mixture of both, enhancing its usability across different applications.

Importance of Sourcing from Chinese Suppliers

China has rapidly developed a robust manufacturing sector, which includes welding materials

. Several factors contribute to the attractiveness of sourcing ER70S welding wire from Chinese suppliers1. Cost-Effectiveness Chinese manufacturers often offer competitive pricing due to lower labor and production costs. This affordability allows companies in different sectors to access high-quality welding materials without exceeding budget constraints.

china er70s welding wire supplier

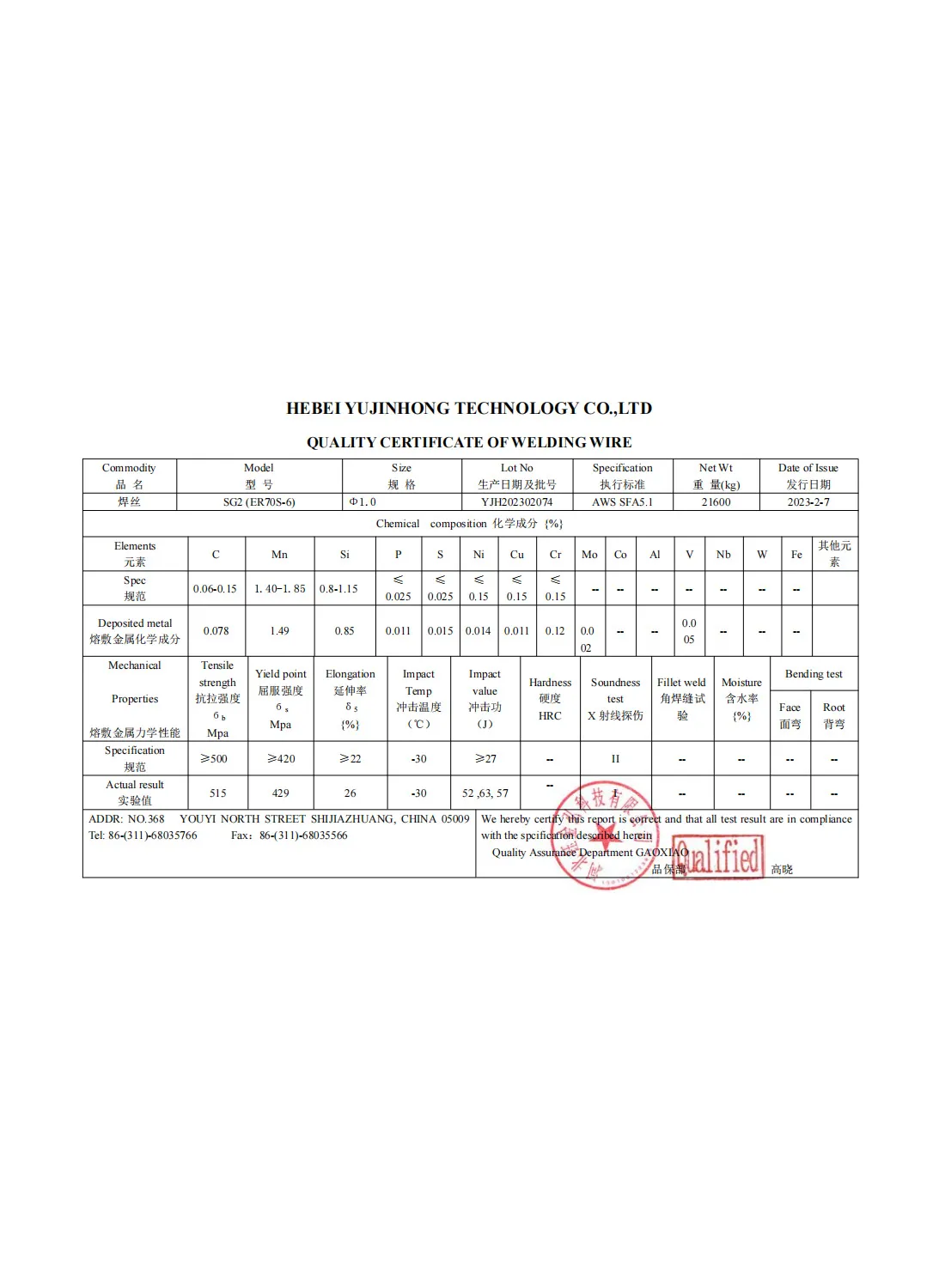

2. Quality Assurance Many Chinese suppliers adhere to international quality standards, including ISO certifications. They utilize advanced manufacturing technologies and quality control processes to ensure their products meet stringent requirements.

3. Diverse Product Range Chinese suppliers generally provide a wide variety of ER70S welding wires, catering to different specifications and customer needs. This diversity allows businesses to select the appropriate wire for their specific applications.

4. Export Capabilities With a well-established export infrastructure, Chinese suppliers can efficiently ship products worldwide. This means that companies abroad can easily access the welding wire they need, regardless of their location.

Choosing the Right Supplier

When selecting a China-based ER70S welding wire supplier, it is crucial to consider several factors, including the supplier's reputation, product quality, and customer service. Thorough research, including customer reviews and testimonials, can provide valuable insight into the reliability of a supplier. Furthermore, requesting samples and certifications can help ensure that the welding wire meets specific industry standards.

Conclusion

In summary, ER70S welding wire is an essential consumable in the welding industry, known for its versatility and reliability. Chinese suppliers have emerged as key players in this market, providing a combination of cost-effectiveness, quality assurance, and a diverse product range. By carefully selecting the right supplier, businesses can enhance their welding operations and achieve superior results.

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025

-

Arc Welding Electrodes AWS E7024 – High Deposition, Smooth FinishNewsJul.30,2025

-

E7016 Welding Rods for Smooth, Low Hydrogen Welding PerformanceNewsJul.29,2025