Leading Supplier of China Welding Electrode 7018 for High-Quality Welds

China Welding Electrode 7018 Supplier A Comprehensive Overview

Welding is an essential process in various industries, including construction, manufacturing, and automotive. Among the myriad of welding electrodes available, the 7018 electrode stands out due to its versatility and effectiveness. This article will delve into the importance of 7018 welding electrodes, the characteristics that make them desirable, and an overview of suppliers, particularly from China.

What is a 7018 Welding Electrode?

The 7018 welding electrode is a low hydrogen iron powder electrode primarily used in arc welding. It is classified under the American Welding Society (AWS) standards, where the numbers represent specific properties of the electrode. The 70 indicates that the electrode can produce a tensile strength of 70,000 psi, and the 18 signifies that it contains about 0.08 - 0.12% carbon, alongside a balanced composition of manganese and silicon. The designation also implies that it is suitable for welding low alloy steels, which are common in structural projects.

Key Characteristics of 7018 Electrodes

1. Low Hydrogen Content One of the most significant features of the 7018 electrode is its low hydrogen content, which minimizes the risk of hydrogen-induced cracking in welded joints. This property makes it ideal for critical applications such as pressure vessels and bridges.

2. High Strength With a tensile strength of 70,000 psi, 7018 electrodes are designed to withstand heavy loads and high-stress conditions. This makes them a preferred choice for construction involving structural steel.

3. Good Arc Stability The design of the 7018 electrode ensures smooth arc stability and minimization of spatter during the welding process. This feature results in a cleaner finish and reduces the time spent on post-weld cleanup.

4. Versatile Use Suitable for both AC and DC currents, 7018 electrodes can be used in various welding positions, making them adaptable to different job requirements.

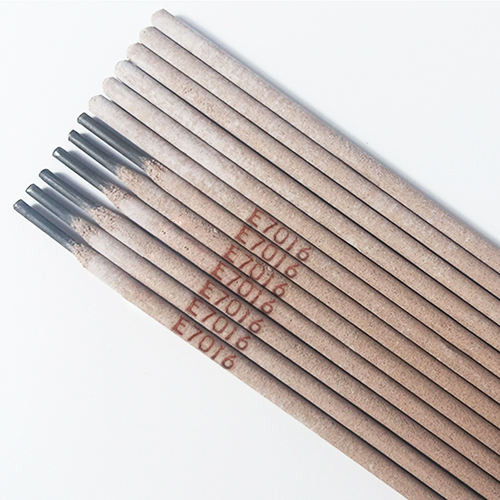

china welding electrode 7018 supplier

5. Excellent Toughness The toughness ensures that welds can perform under extreme conditions, which is essential for structural integrity in demanding environments such as offshore constructions or heavy machinery manufacturing.

The Role of Chinese Suppliers

China has established itself as a leading supplier of welding consumables, including 7018 welding electrodes. The country's manufacturing capabilities allow for mass production of high-quality electrodes that meet international standards. Many Chinese suppliers utilize advanced welding technology and stringent quality control measures to ensure that their products consistently deliver the desired performance.

1. Cost-Effectiveness Chinese suppliers often offer competitive pricing, making the 7018 electrodes accessible to various businesses, from small workshops to large construction and manufacturing firms. This affordability, combined with quality, makes China an attractive source for welders globally.

2. Diverse Product Range Many suppliers in China provide a range of welding electrodes, including different diameters and coating types. This variety allows customers to choose the right product tailored to their specific welding tasks.

3. Export Capabilities Equipped with robust logistics and export frameworks, Chinese suppliers successfully meet the demands of international markets. Their ability to ship products quickly and efficiently enhances reliability for far-flung buyers.

4. Innovation and Technology Continuous investment in research and development has allowed Chinese manufacturers to innovate and improve electrode designs to enhance performance and usability.

Conclusion

Choosing the right welding electrode is crucial for achieving strong and durable welds. The 7018 welding electrode is a popular choice due to its superior characteristics, such as low hydrogen content, high tensile strength, and versatility. Chinese suppliers play a crucial role in this market by providing a cost-effective, high-quality solution to meet the increasing global demand for welding consumables. As industries continue to grow and evolve, the significance of reliable suppliers like those in China will remain paramount in supporting welding professionals worldwide.

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025

-

Arc Welding Electrodes AWS E7024 – High Deposition, Smooth FinishNewsJul.30,2025