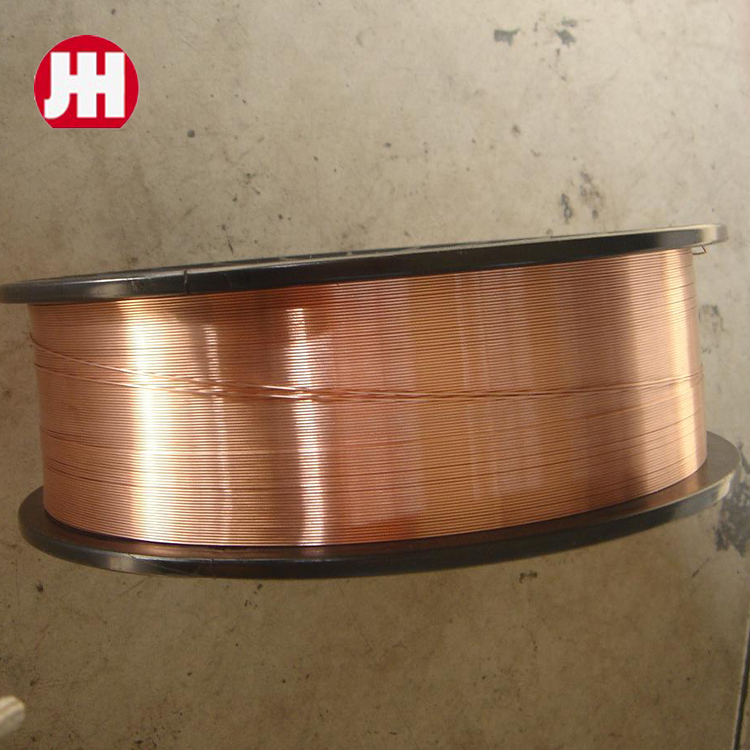

Supplier for 0.8mm MIG Wire for Welding Applications and Projects

Understanding MIG Welding and the Importance of Choosing the Right 0.8mm Wire Supplier

MIG (Metal Inert Gas) welding is one of the most popular welding processes used in various industries today. It is valued for its efficiency, speed, and versatility. At the heart of this process is the welding wire, and for many applications, 0.8mm MIG wire is the preferred choice. The selection of a reliable 0.8mm MIG wire supplier can significantly impact the quality of your welding projects.

What is MIG Welding?

MIG welding, also known as Gas Metal Arc Welding (GMAW), involves feeding a continuous solid wire electrode through a welding gun. This wire melts as it contacts the workpiece, forming a weld pool that cools and solidifies to create a strong joint. The process uses an inert gas, typically argon or carbon dioxide, to shield the weld from atmospheric contamination, ensuring the integrity of the weld.

The Role of 0.8mm MIG Wire

The diameter of the MIG welding wire is a crucial factor in determining the welder's compatibility with the materials being joined, as well as the overall effectiveness of the weld. A 0.8mm wire is commonly used for welding thinner materials, making it ideal for sheet metal applications in automotive repair and fabrication. The fine diameter allows for greater control and precision, enabling the welder to make intricate joints without risking burn-through.

Why Choosing the Right Supplier Matters

When it comes to MIG welding, the quality of the wire can significantly influence the final results. A reputable supplier will provide consistent, high-quality wire that meets industry standards. Poor quality wire can lead to a range of issues, including

1. Inconsistent Weld Quality Low-grade wire may lead to weak welds, causing structural failures and safety hazards. 2. Increased Spattering Inferior welding wire can produce excessive spatter, requiring additional cleanup and decreasing overall productivity. 3. Feed Problems If the wire is not manufactured with precision, it can lead to feed issues, resulting in downtime and inefficiency. 4. Higher Costs While cheap wire may seem like a bargain, the long-term costs associated with repairs and poor-quality work can be significant.

mig wire 0.8mm supplier

Key Features to Look for in a Supplier

When searching for a 0.8mm MIG wire supplier, consider the following criteria to ensure you’re making the best choice

1. Quality Assurance Look for suppliers who adhere to industry standards and perform rigorous testing on their products. Certifications such as ISO can be indicators of a reputable supplier. 2. Product Range A good supplier will offer a variety of wire types, such as solid, flux-cored, and specialty wires. This variety allows you to select the right wire for your specific application.

3. Customer Support Suppliers that provide excellent customer service, technical support, and trouble-shooting assistance can be invaluable. Knowledgeable staff can help you choose the right products for your needs.

4. Competitive Pricing While price shouldn't be the only factor, you want to find a supplier that offers reasonable pricing for high-quality products. Compare prices among different suppliers to ensure you’re getting the best deal.

5. Timely Delivery Reliability in shipping is crucial for maintaining the flow of your projects. A supplier that can assure timely delivery will help you minimize downtime.

Conclusion

In summary, the selection of a suitable 0.8mm MIG wire supplier is fundamental to achieving high-quality welding results. The right wire combined with proper welding techniques can lead to strong, durable welds that withstand the test of time. As the industry continues to evolve, keeping an eye on new suppliers and advancements in wire technology can give your projects a competitive edge. Ensuring that you invest in quality materials will not only enhance the efficiency of your welding processes but also guarantee the safety and longevity of your welded structures. Whether you are involved in automotive manufacturing, construction, or metal fabrication, choosing the right MIG wire supplier should be a top priority in your operations.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025