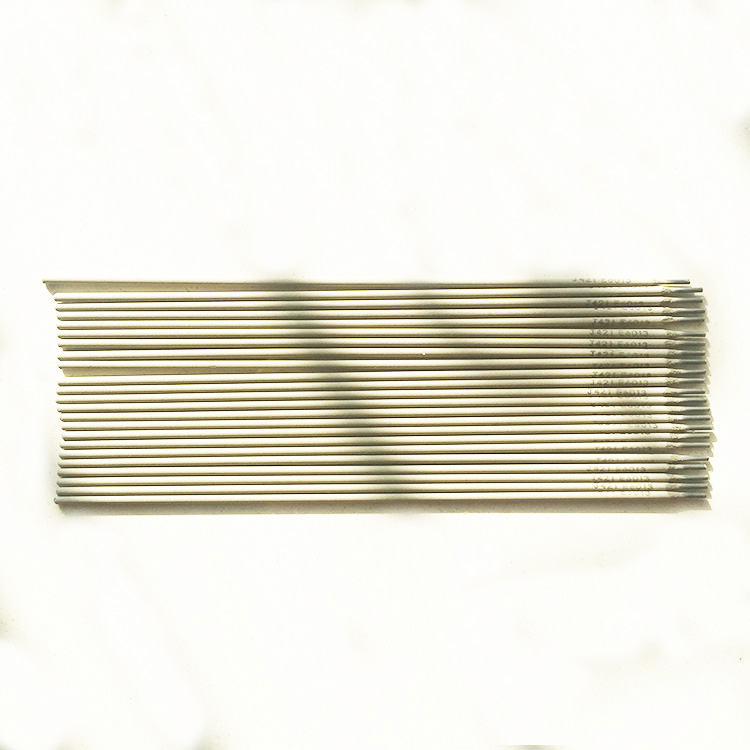

solder wire 0.8mm

Exploring the Importance of 0.8mm Solder Wire in Electronics

Soldering is a critical process in the world of electronics, serving as the backbone for joining electrical components together. Among the various soldering materials available, 0.8mm solder wire has gained prominence for its versatility and effectiveness. This article delves into the significance of 0.8mm solder wire, its applications, advantages, and tips for optimal use.

Exploring the Importance of 0

.8mm Solder Wire in ElectronicsOne of the key advantages of 0.8mm solder wire is its adaptability. It is thin enough to be controlled easily, allowing for intricate soldering in tight spaces, which is often required in densely packed circuit boards. This diameter provides sufficient material to ensure a strong connection without excessive buildup, which could potentially lead to shorts or other electrical failures. Furthermore, the 0.8mm size is compatible with various soldering techniques, be it through-hole soldering, surface-mount technology, or even rework processes.

solder wire 0.8mm

Another significant aspect of 0.8mm solder wire is its composition. While traditional solder often contains lead, there is a growing trend towards lead-free alternatives due to health and environmental concerns. Lead-free solder typically consists of tin mixed with copper, silver, or other metals, creating a safe yet effective alternative for soldering electronics. Many manufacturers offer 0.8mm solder wire in lead-free variants, allowing for compliance with international standards such as RoHS (Restriction of Hazardous Substances).

When using 0.8mm solder wire, several best practices can enhance the quality of your solder joints. First and foremost, ensuring that your soldering iron is properly heated is essential. A temperature range of 350°C (662°F) is generally suitable for most soldering tasks involving 0.8mm wire. Additionally, maintaining a clean iron tip can prevent oxidation, ensuring optimal heat transfer and allowing for smoother solder application.

Proper technique also matters when working with solder wire. It's advisable to heat both the component lead and the PCB pad simultaneously while feeding the solder into the joint. This process promotes a uniform flow of solder and ensures a reliable connection. It's also important to apply the solder sparingly, as too much solder can create joints that are prone to accidental shorts.

In conclusion, 0.8mm solder wire is an indispensable tool in electronics soldering, offering a perfect balance of functionality and ease of use. Its versatility makes it suitable for a wide range of applications, from DIY projects to professional manufacturing. By understanding its properties and adhering to best practices, hobbyists and professionals alike can achieve high-quality results, ensuring their electronic devices function reliably. Whether you're assembling a new gadget or repairing an old one, having a spool of 0.8mm solder wire on hand is essential for any electronic enthusiast.

-

Premium 7018 Welding Rods Electrodes for Strong WeldsNewsJul.23,2025

-

E71T-1 Shielding Gas for Gas Shielded Cored Wire Welding SolutionsNewsJul.22,2025

-

Premium Submerged Arc Welding Wire | Efficient Quality SolutionNewsJul.21,2025

-

Premium Solid MIG Welding Wire - Strong, Low-Spatter WeldsNewsJul.21,2025

-

E71T-GS Self-Shielding Welding Wire | Gasless Outdoor UseNewsJul.20,2025

-

E312 Welding Electrode - High Corrosion Resistance & All-Purpose UseNewsJul.20,2025