wholesale 035 er70s 6 welding wire manufacturer

The Significance of ER70S-6 Welding Wire in Wholesale Manufacturing

Welding is a critical process in a wide range of industries, including construction, automotive, and manufacturing. One of the most commonly used welding wires is ER70S-6, a filler metal known for its excellent arc stability and versatility. In the realm of wholesale manufacturing, sourcing high-quality ER70S-6 welding wire is essential for companies aiming to deliver durable and reliable products. This article will explore the characteristics of ER70S-6 welding wire, its applications, and the importance of selecting the right manufacturer.

Understanding ER70S-6 Welding Wire

ER70S-6 is a solid copper-coated welding wire designed for use in gas metal arc welding (GMAW) and flux-cored arc welding (FCAW). The 'ER' in the designation stands for 'electrode filler material,' while '70' indicates the minimum tensile strength of 70,000 psi. The 'S' denotes that the wire is solid, and the '-6' specifies the specific composition of silicon and manganese, which enhances the wire's deoxidizing properties.

ER70S-6 is particularly favored for its ability to produce high-quality welds on a variety of materials, including carbon steel, low alloy steel, and some nickel-based alloys. With its excellent wetting action and low spatter levels, this welding wire contributes to clean finishes that require minimal post-weld cleanup. These attributes make ER70S-6 a popular choice in industries where precision and strength are paramount.

Applications of ER70S-6 Welding Wire

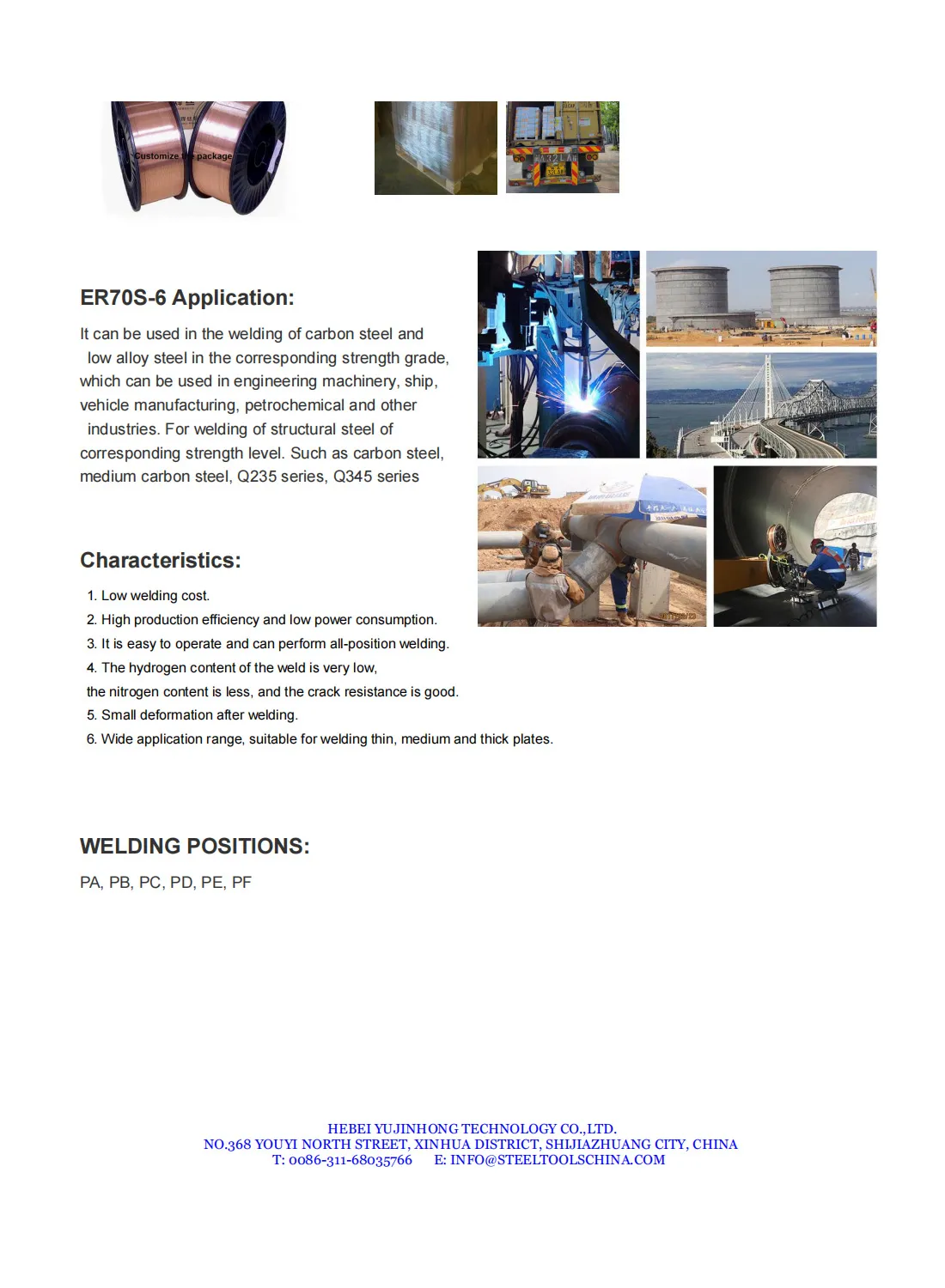

The versatility of ER70S-6 welding wire allows it to be used in a wide array of applications. Primary sectors utilizing this welding wire include

1. Automotive Manufacturing The automotive industry relies heavily on ER70S-6 for assembling vehicle bodies and components. The wire's strength and ductility are crucial for ensuring the welds can withstand the rigors of everyday use.

2. Construction In construction, ER70S-6 is often employed for structural steel fabrication. Its ability to provide strong and reliable joints is vital for building infrastructures that can endure various environmental conditions.

3. Shipping and Marine Applications The marine industry takes advantage of ER70S-6 for shipbuilding and repair. The wire's resistance to corrosion and ability to be welded in different positions make it ideal for underwater and above-water applications.

wholesale 035 er70s 6 welding wire manufacturer

4. General Fabrication Whether for creating custom metal structures or fabricating equipment, ER70S-6 is widely used due to its versatility and compatibility with various welding techniques.

Importance of Choosing the Right Manufacturer

When it comes to wholesale procurement of ER70S-6 welding wire, selecting a reputable manufacturer is crucial. The quality of the welding wire directly impacts the final product's performance and longevity. Companies should consider several factors when choosing a manufacturer

1. Quality Assurance A reliable manufacturer should adhere to strict quality control standards. Certifications such as ISO 9001 indicate a commitment to maintaining high-quality production processes.

2. Material Composition Understanding the chemical composition of the welding wire is essential. Manufacturers should provide detailed specifications to ensure the wire meets the necessary industry standards.

3. Production Capacity A manufacturer with sufficient production capabilities can meet large orders without compromising quality. This reliability is particularly important for wholesale users who depend on consistent supply.

4. Technical Support Manufacturers that offer technical support and guidance can help businesses troubleshoot issues and optimize their welding processes, resulting in better overall results.

5. Competitive Pricing While quality should never be compromised, competitive pricing is also essential for wholesale buyers. Manufacturers that provide a balance of both can help businesses maintain profitability without sacrificing product integrity.

Conclusion

ER70S-6 welding wire plays a vital role in various manufacturing processes, ensuring strong and reliable welds across multiple industries. For companies engaging in wholesale procurement, selecting a reputable manufacturer equipped with high-quality materials and excellent support is essential for achieving successful outcomes. As industries continue to evolve, the demand for high-quality welding wires like ER70S-6 will only grow, emphasizing the need for reliable sources in the market.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025