wholesale 3.2mm 7018 welding electrode manufacturer

Understanding Wholesale 3.2mm 7018 Welding Electrode Manufacturing

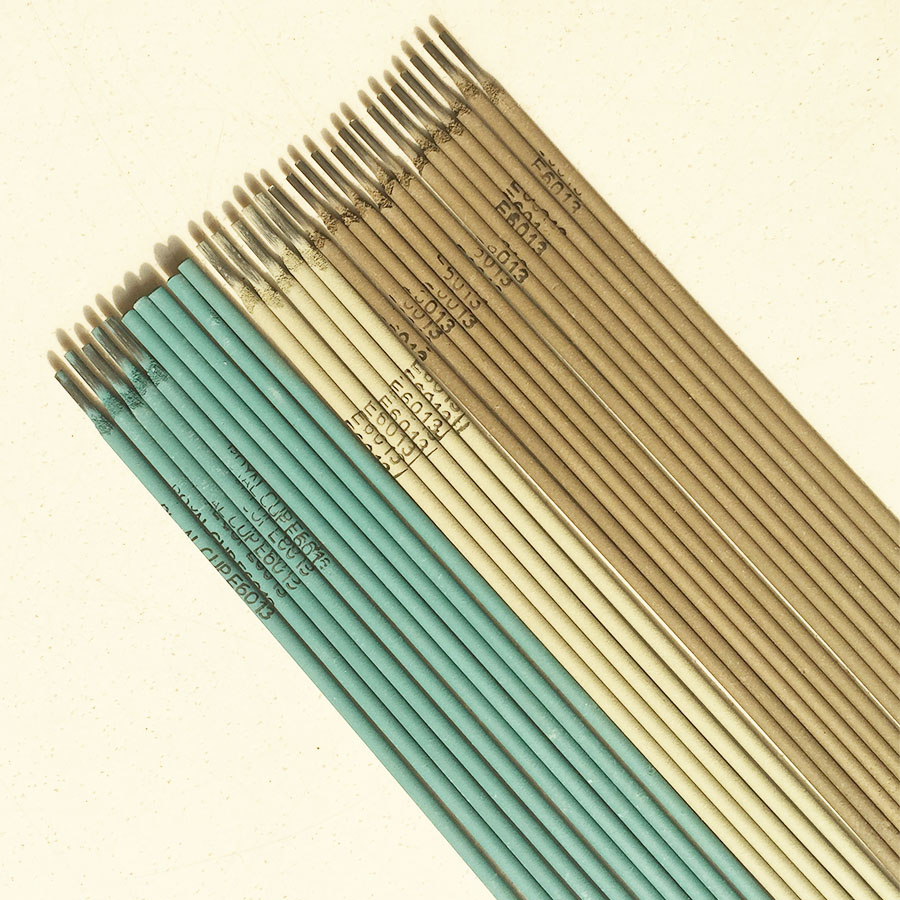

Welding is a fundamental process in various industries, ranging from construction to automotive manufacturing, and choosing the right welding electrode is vital for ensuring quality and strength in welded joints. Among the myriad of welding electrodes available in the market, the 3.2mm 7018 welding electrode has garnered a significant reputation due to its robust properties and versatility.

The 7018 welding electrode is an iron powder low-hydrogen electrode that is primarily used for welding structural steel, low-alloy steel, and some non-ferrous metals. The “70” in its designation refers to its minimum tensile strength of 70,000 psi, while the 18 signifies that it can be used in all-position welding. The 3.2mm diameter makes it suitable for various welding applications, striking an excellent balance between penetration and fusion, making it a preferred choice among welding professionals.

Manufacturing of 3.2mm 7018 welding electrodes involves several meticulous steps to ensure that each electrode meets industry standards and provides the desired performance. The entire process begins with the selection of high-quality raw materials, which typically includes mild steel wire, a unique flux mixture, and iron powder. The flux coating is essential as it provides a protective layer during welding, reducing oxidation and contamination of the weld pool.

Once the materials are sourced, the manufacturing process involves several stages, including wire drawing, coating, and baking. The wire drawing process shapes the steel wire into the desired diameter. In the case of the 3.2mm 7018 electrode, precision is crucial to maintain consistency in performance. After this, the wire is coated with flux, which is often a combination of calcium carbonate, silica, and other proprietary compounds.

wholesale 3.2mm 7018 welding electrode manufacturer

One of the most critical phases in manufacturing these electrodes is the drying or baking process. This step is crucial to ensure that the electrodes have minimal moisture content, which can lead to hydrogen embrittlement in the weld, compromising its integrity. Manufacturers meticulously control temperature and humidity during this stage to achieve optimal conditions.

Quality control is an integral part of the manufacturing process. Each batch of 3.2mm 7018 welding electrodes undergoes rigorous testing to assess their mechanical properties, structural integrity, and performance under various conditions. This includes tensile strength tests, bend tests, and impact tests to ensure they meet the stringent standards required for industrial applications.

The wholesale market for 3.2mm 7018 welding electrodes has seen significant growth as industries continue to seek reliable and high-performance welding materials. Welding suppliers and manufacturers that focus on wholesale distribution can offer competitive pricing and bulk purchasing options, making it beneficial for contractors and companies engaged in large-scale welding projects.

In conclusion, the manufacturing of 3.2mm 7018 welding electrodes combines precision engineering, high-quality raw materials, and rigorous testing to produce a reliable product that meets the demands of modern welding applications. As industries evolve, the demand for high-quality electrodes will continue to grow, reinforcing the importance of efficient manufacturing practices in the wholesale market.

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025