Berita

-

The 6010 welding rod is a popular choice in the welding industry, known for its versatility and unique characteristics.Baca selengkapnya

The 6010 welding rod is a popular choice in the welding industry, known for its versatility and unique characteristics.Baca selengkapnya -

Welding is a critical process in various industries, and the selection of welding wire material plays a significant role in the quality and efficiency of the weld.Baca selengkapnya

Welding is a critical process in various industries, and the selection of welding wire material plays a significant role in the quality and efficiency of the weld.Baca selengkapnya -

Submerged arc welding (SAW) is a highly efficient and versatile welding process used extensively in various industries.Baca selengkapnya

Submerged arc welding (SAW) is a highly efficient and versatile welding process used extensively in various industries.Baca selengkapnya -

In the bustling and often hazardous environment of shipyards, where welding and other hot work activities are regularly undertaken, adherence to stringent safety regulations is paramount to prevent catastrophic accidents.Baca selengkapnya

In the bustling and often hazardous environment of shipyards, where welding and other hot work activities are regularly undertaken, adherence to stringent safety regulations is paramount to prevent catastrophic accidents.Baca selengkapnya -

Are you in the market for a reliable and efficient welding solution? Look no further! In this article, we will explore the world of flux core welders and the various flux core wire types available for sale. Discover how these powerful tools can revolutionize your welding projects and enhance your productivity.Baca selengkapnya

Are you in the market for a reliable and efficient welding solution? Look no further! In this article, we will explore the world of flux core welders and the various flux core wire types available for sale. Discover how these powerful tools can revolutionize your welding projects and enhance your productivity.Baca selengkapnya -

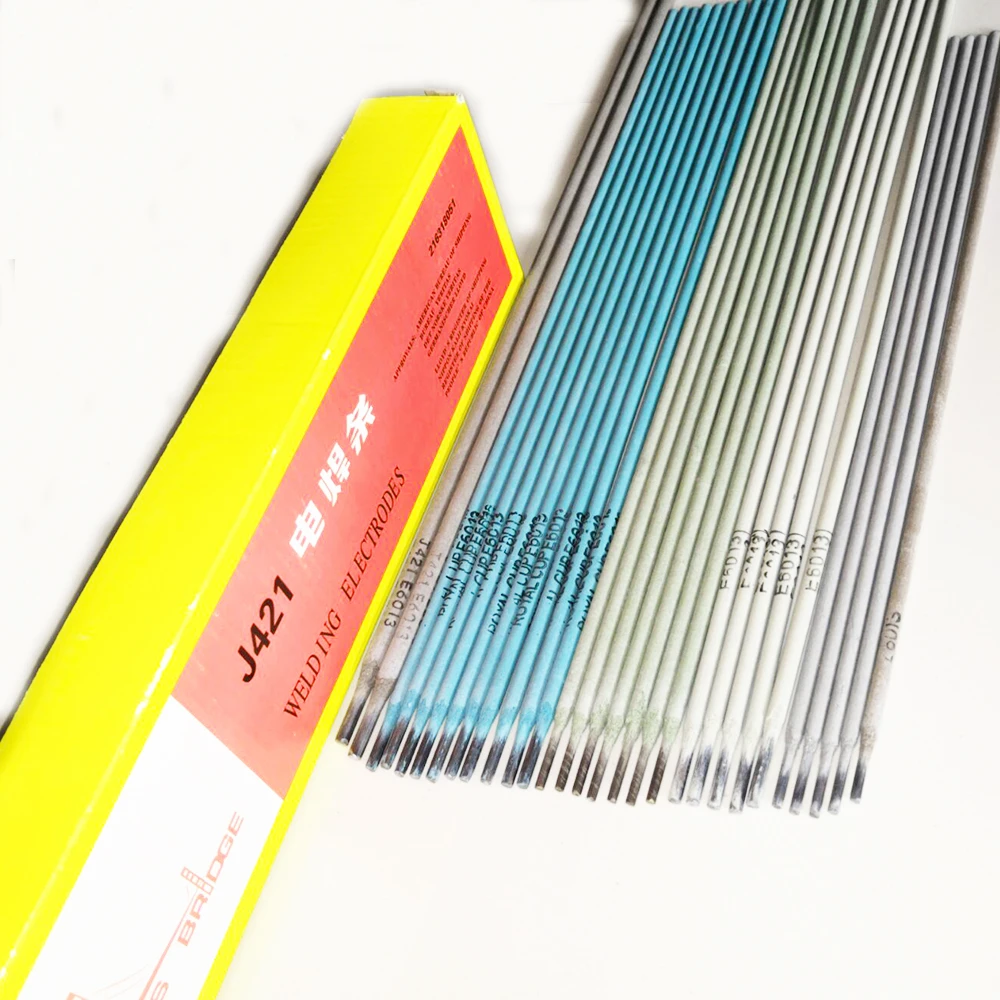

Welding is a crucial process in various industries, enabling the joining of metals through fusion. In this article, we will delve into the significance of bulk welding rods and welding electrodes, highlighting their roles and applications in the welding process.Baca selengkapnya

Welding is a crucial process in various industries, enabling the joining of metals through fusion. In this article, we will delve into the significance of bulk welding rods and welding electrodes, highlighting their roles and applications in the welding process.Baca selengkapnya -

Flux wire welding, also known as flux-cored arc welding (FCAW), is a highly efficient and versatile welding process that has gained immense popularity in various industries. Unlike traditional MIG welding, which requires an external shielding gas, flux wire welding utilizes a hollow wire filled with flux.Baca selengkapnya

Flux wire welding, also known as flux-cored arc welding (FCAW), is a highly efficient and versatile welding process that has gained immense popularity in various industries. Unlike traditional MIG welding, which requires an external shielding gas, flux wire welding utilizes a hollow wire filled with flux.Baca selengkapnya -

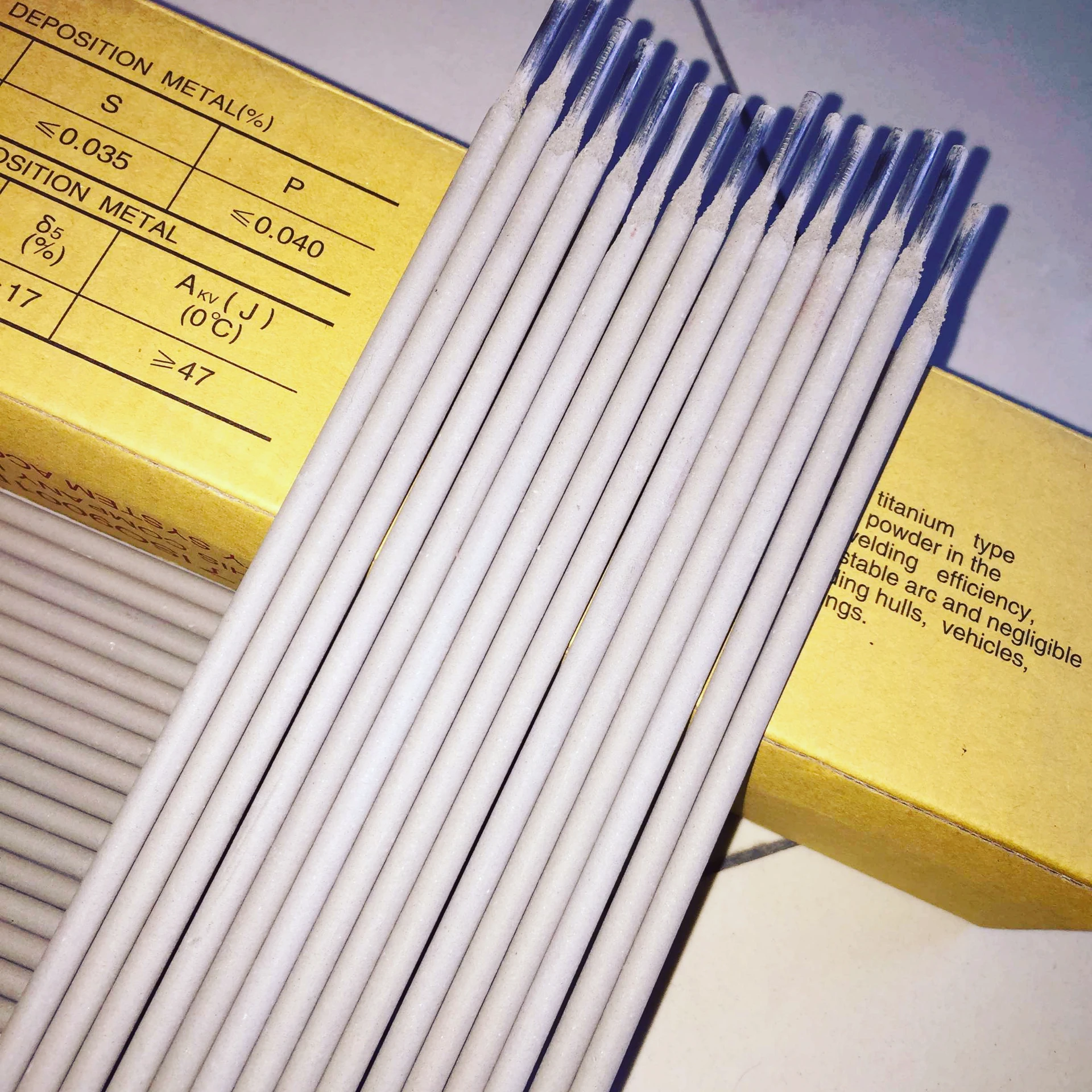

When it comes to welding, choosing the right materials is crucial for achieving strong and durable welds. In this article, we will explore the exceptional qualities of 6013 welding rods and E6013 electrodes, which are widely regarded as the perfect welding solution for various applications.Baca selengkapnya

When it comes to welding, choosing the right materials is crucial for achieving strong and durable welds. In this article, we will explore the exceptional qualities of 6013 welding rods and E6013 electrodes, which are widely regarded as the perfect welding solution for various applications.Baca selengkapnya -

Mig and flux core welders are popular welding machines used in various industries. Mig welding, also known as Gas Metal Arc Welding (GMAW), involves feeding a wire electrode through a welding gun and creating an arc between the electrode and the workpiece. Flux core welding, on the other hand, uses a hollow wire electrode filled with flux to create the arc.Baca selengkapnya

Mig and flux core welders are popular welding machines used in various industries. Mig welding, also known as Gas Metal Arc Welding (GMAW), involves feeding a wire electrode through a welding gun and creating an arc between the electrode and the workpiece. Flux core welding, on the other hand, uses a hollow wire electrode filled with flux to create the arc.Baca selengkapnya -

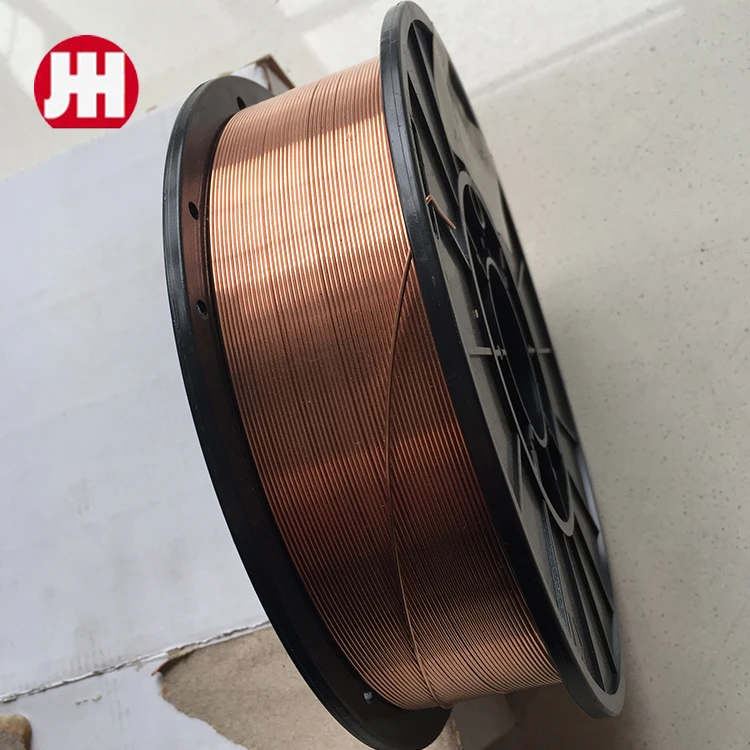

Mig (Metal Inert Gas) welding has become increasingly popular in various industries due to its efficiency and versatility. One of the key components in Mig welding is the Mig wire, which comes in various types, including Mig copper wire and copper-coated Mig wire. In this article, we will delve into the characteristics, applications, and benefits of these two types of Mig wires.Baca selengkapnya

Mig (Metal Inert Gas) welding has become increasingly popular in various industries due to its efficiency and versatility. One of the key components in Mig welding is the Mig wire, which comes in various types, including Mig copper wire and copper-coated Mig wire. In this article, we will delve into the characteristics, applications, and benefits of these two types of Mig wires.Baca selengkapnya -

Before buying one, make sure your welding current is supported by your welding rods.Baca selengkapnya

Before buying one, make sure your welding current is supported by your welding rods.Baca selengkapnya -

In the bustling shipyard, welding tasks are not uncommon; nonetheless, they demand an unwavering commitment to safety protocols to prevent tragedies.Baca selengkapnya

In the bustling shipyard, welding tasks are not uncommon; nonetheless, they demand an unwavering commitment to safety protocols to prevent tragedies.Baca selengkapnya