304 TIG Welding Wire Suppliers and Manufacturers for Quality Welding Solutions

304 TIG Welding Wire Manufacturers A Comprehensive Overview

TIG (Tungsten Inert Gas) welding is a widely used welding process favored for its precision and ability to weld a variety of materials, especially stainless steel. Among the various types of welding wires available, 304 TIG welding wire stands out due to its versatility and corrosion resistance, making it a preferred choice in numerous applications, from automotive to aerospace and biomedical industries.

304 TIG Welding Wire Manufacturers A Comprehensive Overview

Leading manufacturers of 304 TIG welding wire usually employ advanced metallurgical techniques and state-of-the-art equipment in their production processes. They often source high-grade raw materials to ensure the integrity of the wire. The wire must undergo various tests, including tensile strength, elongation, and corrosion resistance tests, to comply with international standards such as ASTM and AWS.

304 tig welding wire manufacturers

One of the key factors customers consider when choosing a 304 TIG welding wire manufacturer is the consistency and reliability of the product. Reputable manufacturers produce welding wire that exhibits a uniform diameter and smooth finish, which are essential for achieving an even and stable arc during welding. Customers also look for manufacturers that offer a range of wire diameters to accommodate different welding applications.

In addition to quality, manufacturers often provide technical support and guidance to their customers. This includes assistance with choosing the correct filler material, understanding welding parameters, and addressing any technical challenges that may arise during the welding process. Effective communication and support can significantly improve the overall welding quality and efficiency.

Sustainability practices are becoming increasingly important in the welding wire industry. Many manufacturers are adopting eco-friendly processes and materials, reducing waste and carbon footprints. This shift not only benefits the environment but also appeals to customers who prioritize sustainability in their procurement processes.

In conclusion, choosing the right 304 TIG welding wire manufacturer is crucial for achieving high-quality welds in various applications. Customers should consider factors such as product quality, technical support, and sustainability practices when selecting a supplier. With several reputable manufacturers in the market, businesses can find a partner that meets their specific welding needs and contributes to their success in their respective industries. As the demand for high-quality welding materials continues to rise, manufacturers must stay ahead of industry trends to meet customer expectations effectively.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

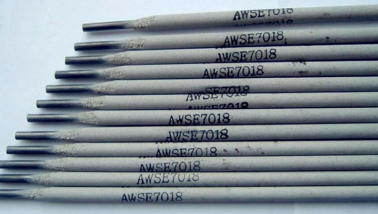

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025