High-Quality China E6010 Welding Rod Manufacturers

The Rise of E6010 Welding Rod Manufacturers in China

In the dynamic landscape of manufacturing, China has carved out a significant niche in the production of welding consumables, notably E6010 welding rods. These rods are essential in various welding applications, particularly in the construction and repair of pipelines and heavy-duty structures. With the global demand for reliable and efficient welding materials surging, Chinese manufacturers have positioned themselves as leaders in this market.

What are E6010 Welding Rods?

E6010 welding rods are a type of stick electrode commonly used in arc welding. They are characterized by their ability to create a stable arc and produce high-quality, strong welds. The E in E6010 indicates that it is an electrode; the 60 refers to the minimum tensile strength of 60,000 psi, and the 10 indicates the position in which the electrode can be used (all positions). Their versatility and efficiency make E6010 rods popular for fieldwork, especially in environments where welding conditions are less than ideal.

Chinese Manufacturers Leading the Market

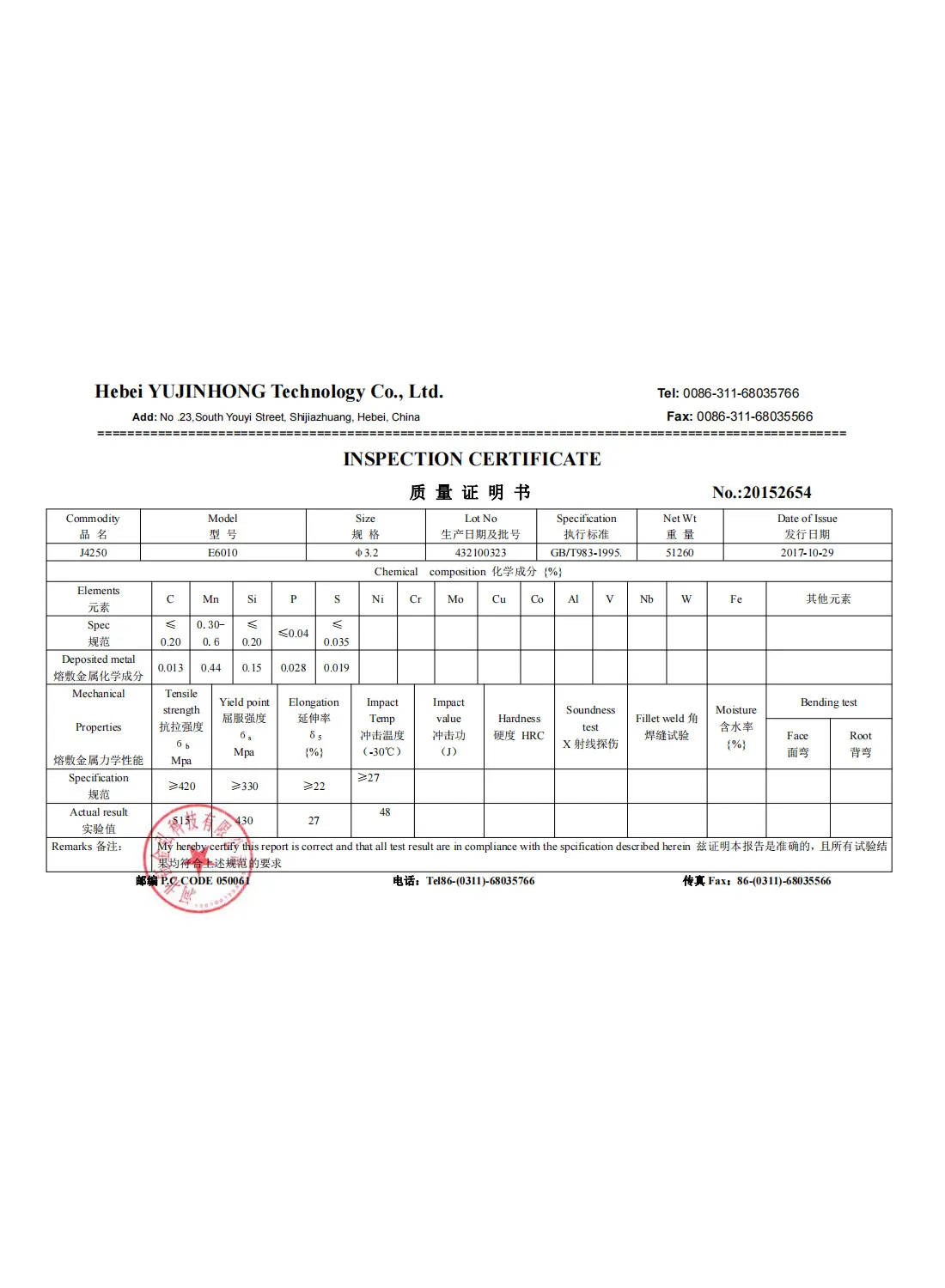

Chinese manufacturers of E6010 welding rods have harnessed advanced technologies and efficient production methodologies to meet the global demand. The integration of modern equipment and stringent quality control measures allows them to produce high-quality rods that comply with international standards. These manufacturers operate at large scales, enabling them to offer competitive pricing while maintaining the quality required by industries worldwide.

A standout feature of Chinese manufacturers is their commitment to research and development. Many companies invest in innovating their products, ensuring that they adapt to the evolving needs of various industries. This includes developing welding rods that are not only efficient but also environmentally friendly. For instance, some manufacturers are focusing on reducing the environmental impact of their production processes and the materials used in their welding rods.

Export Opportunities and Global Reach

china e6010 welding rod manufacturers

With their robust production capabilities, Chinese E6010 welding rod manufacturers have expanded their reach across international markets. The global construction, shipbuilding, and petrochemical industries are significant consumers of these products. Chinese manufacturers have established strong export channels, allowing them to penetrate markets in Europe, North America, and beyond.

Moreover, partnerships with distributors and local suppliers in various countries have facilitated a steady supply of E6010 rods. This global network ensures that manufacturers can respond quickly to market demands and customer needs, solidifying their position in the international arena.

Challenges and Future Prospects

Despite the advantages, Chinese E6010 welding rod manufacturers face challenges in terms of competition and trade regulations. Other countries have also recognized the potential of the welding consumables market, leading to increased competition. Additionally, fluctuating raw material prices and stringent import tariffs can impact the affordability and accessibility of Chinese products in some markets.

However, the outlook remains positive for Chinese manufacturers. With ongoing innovations, increased automation in production, and a strong focus on quality, they are well-positioned to meet growing global demands. As industries continue to expand and evolve, the need for reliable welding solutions will only increase, paving the way for future growth in the E6010 welding rod manufacturing sector.

Conclusion

In summary, the prominence of E6010 welding rod manufacturers in China reflects the country’s commitment to quality and innovation in manufacturing. As they continue to adapt to market demands and navigate challenges, Chinese manufacturers are set to maintain their standing as key players in the global welding industry. The future looks bright for them, as the need for robust welding solutions becomes increasingly vital in numerous sectors worldwide.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025