China 5/32 Welding Rod 7018 Specifications and Usage Guide for Quality Welding

The Importance of China 5/32 Welding Rod 7018 in Modern Welding Applications

Welding is a critical process in various industries, from construction and manufacturing to automotive and shipbuilding. Among the various welding rods available, the China 5/32 welding rod 7018 stands out as a popular choice for many welders due to its versatility, strength, and ease of use. This article will explore the key features and advantages of the 7018 welding rod while highlighting its applications in modern welding practices.

The 7018 welding rod is classified as an E7018 electrode, which indicates its specific characteristics as per the American Welding Society (AWS) standards. The “E” denotes that it is an electrode used in welding, while “70” indicates a minimum tensile strength of 70,000 psi. The 1 signifies the welding position (all positions), and the “8” indicates the use of an low hydrogen coating. This low hydrogen aspect is particularly significant as it minimizes the risk of hydrogen-induced cracking in the weld, making it suitable for high-strength applications.

The Importance of China 5/32 Welding Rod 7018 in Modern Welding Applications

Another important aspect of the 7018 rod is its versatility. Welders can use it in various positions, including flat, horizontal, vertical, and overhead, making it suitable for diverse projects. This flexibility allows fabricators and welders to adapt to different job requirements without needing multiple types of electrodes, resulting in cost and time savings.

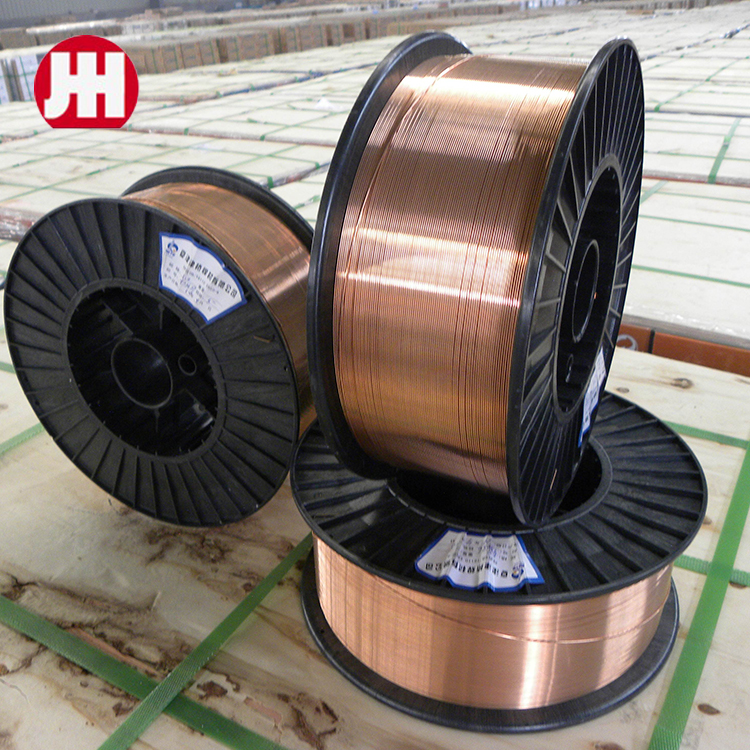

china 5/32 welding rod 7018

Moreover, the China 5/32 welding rod 7018 is known for its ease of use. The rod features excellent arc stability, which allows for a smooth welding experience. Welders, both novice and experienced, appreciate this quality, as it helps them maintain better control during the welding process. The flux coating on the rod also helps protect the weld pool from atmospheric contamination, ensuring the integrity of the weld.

In terms of applicability, industries such as construction, shipbuilding, and automotive manufacturing heavily rely on the 7018 welding rod. Its strength and reliability play a pivotal role in creating sturdy and long-lasting structures that can withstand various stressors. Furthermore, in the realm of repairs and maintenance, the 7018 rod proves advantageous for restoring the integrity of damaged machinery and components, enhancing their lifespan.

Despite its many benefits, it is essential for welders to consider proper storage and handling of the China 5/32 welding rod 7018. The rod should be kept in a dry environment to prevent moisture absorption, which can compromise its effectiveness. Additionally, following suitable preheating and post-weld heat treatment processes can further enhance the weld quality and minimize defects.

In conclusion, the China 5/32 welding rod 7018 has established itself as a cornerstone in modern welding applications. Its high tensile strength, versatility, and ease of use make it an essential tool for welders across various industries. As welding technology continues to evolve, the 7018 rod remains a reliable choice for ensuring strong and durable welds in critical applications.

-

3.2mm 7018 Welding Electrode Wholesale Supplier in China Factory Direct Price & High QualityNewsJul.04,2025

-

Stainless Steel Welding Rods for Sale – High Quality 7018 Welding Rods SupplierNewsJul.04,2025

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025