Factories Producing China 6013 Welding Electrodes for Various Applications and Industries

The Landscape of China's 6013 Welding Electrodes Factories

Welding is a vital process in numerous industries, including construction, manufacturing, and automotive. Among the various types of welding electrodes available, the 6013 welding electrodes are particularly popular due to their versatility and effectiveness in various welding applications. China, being a global leader in manufacturing, is home to numerous factories that produce 6013 welding electrodes, playing a significant role in both domestic and international markets.

Overview of 6013 Welding Electrodes

6013 welding electrodes are characterized by their ability to perform well in both alternating and direct current applications. They are primarily designed for mild steel and are commonly used in general fabrication, structural and aesthetic welding. The welding rods feature a rutile coating that provides excellent arc stability, minimal spatter, and a smooth finish, making them ideal for various welding positions.

The combination of good mechanical properties and user-friendly characteristics makes 6013 electrodes a preferred choice for both professional welders and hobbyists. Their ease of use and adaptability to different conditions further enhances their appeal, paving the way for widespread production in China.

The Manufacturing Process

The manufacturing of 6013 welding electrodes involves several key steps. The core of the electrode is crafted from mild steel, which is coated with a mixture of chemicals and materials. This coating formulation plays a critical role in determining the performance of the welding electrode during the welding process.

Key ingredients often include iron powder, mineral salts, and cellulose, all of which contribute to arc stability, slag formation, and deposition efficiency. Factories in China utilize advanced machinery and technology to ensure a consistent and high-quality output of these electrodes, adhering to international standards.

Quality control is paramount during the manufacturing process. Factories implement rigorous testing procedures on each batch of electrodes, assessing factors such as tensile strength, chemical composition, and arc stability. This commitment to quality has positioned Chinese manufacturers as reliable suppliers in the global welding market.

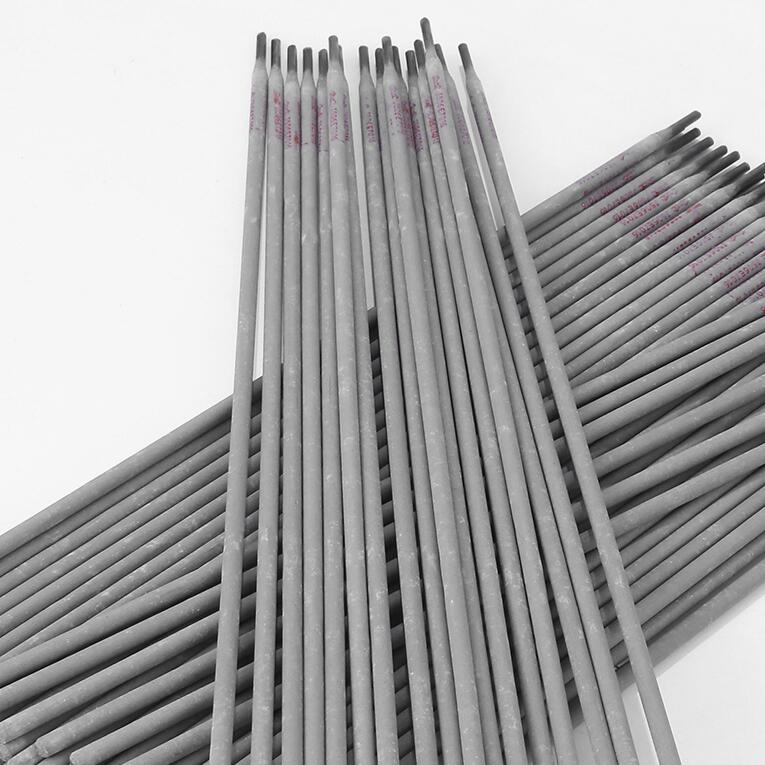

china 6013 welding electrodes factories

Major Players in the Industry

China's 6013 welding electrodes market is populated by several prominent factories and manufacturers. Many of these companies have established extensive distribution networks, enabling them to cater to both domestic demands and international markets.

Some of the major players in the industry emphasize innovation and technology, investing in research and development to improve electrode performance and efficiency. These manufacturers not only focus on the production of 6013 electrodes but also diversify their offerings by producing a range of other welding rods and consumables.

Challenges and Opportunities

Despite the robust growth of the welding electrode sector in China, manufacturers face challenges, including competition from other countries, fluctuating raw material prices, and stringent environmental regulations. However, these challenges also present opportunities for growth and improvement.

The increasing demand for sustainable and eco-friendly manufacturing processes propels companies to invest in cleaner production techniques and alternative materials. Additionally, as industries upgrade their processes and equipment, the need for high-quality welding electrodes continues to rise, allowing manufacturers to expand their market reach.

Conclusion

As a vital component of the welding industry, 6013 welding electrodes hold significant importance in myriad applications. The factories in China producing these electrodes are not only crucial for meeting domestic demands but also make considerable contributions to the global market. With advanced technology, rigorous quality control, and a commitment to ongoing innovation, Chinese manufacturers are well-positioned to remain competitive in the evolving landscape of welding consumables. As they navigate challenges and seize new opportunities, the future for China’s 6013 welding electrode factories looks promising.

-

Welding Rod 2.0 mm for Structural Welding - High Strength & PrecisionNewsJul.25,2025

-

Factory Supply Cast Iron Welding Rods AWS ENi-CI High StrengthNewsJul.24,2025

-

Premium 7018 Welding Rods Electrodes for Strong WeldsNewsJul.23,2025

-

E71T-1 Shielding Gas for Gas Shielded Cored Wire Welding SolutionsNewsJul.22,2025

-

Premium Submerged Arc Welding Wire | Efficient Quality SolutionNewsJul.21,2025

-

Premium Solid MIG Welding Wire - Strong, Low-Spatter WeldsNewsJul.21,2025