e71t-gs gasless flux cored welding wire manufacturers

Understanding E71T-GS Gasless Flux Cored Welding Wire A Guide to Manufacturers and Applications

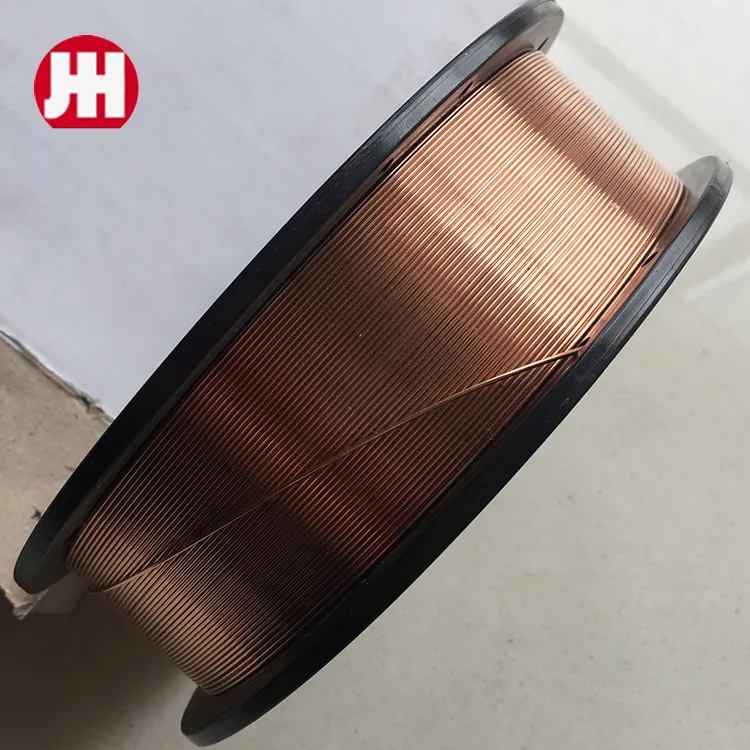

In the world of welding, achieving high-quality results hinges on choosing the right materials. One such material, particularly popular among both hobbyists and professionals, is the E71T-GS gasless flux cored welding wire. Known for its versatility and ease of use, this type of welding wire is ideal for various applications, particularly in outdoor environments or where shielding gas cannot be used. This article aims to explore the characteristics of E71T-GS welding wire, its applications, and the manufacturers who produce it.

What is E71T-GS Welding Wire?

E71T-GS is a type of flux-cored wire that is designed for gasless operation. Unlike traditional MIG welding, which requires a shielding gas to protect the weld pool from contamination, E71T-GS contains a core of flux material that generates its own shielding gas when heated. This makes it ideal for applications where using a gas supply is impractical or impossible.

The designation E71T-GS breaks down as follows - E Indicates it is an electrode (welding wire). - 71 Refers to the minimum tensile strength, which is 71,000 psi. - T Stands for tubular wire (flux-cored). - G Indicates it can be used in a gasless mode. - S Signifies it is suitable for both flat and horizontal position welding.

Advantages of E71T-GS Welding Wire

1. Ease of Use The gasless feature simplifies the welding process, making it accessible for beginners while still being efficient for seasoned welders. 2. Portability Since there is no need for external gas cylinders, welders can work in remote locations without the hassle of transporting additional equipment.

4. Less Cleanup The flow of gas generated by the flux helps to minimize spatter, resulting in a cleaner weld that requires less cleanup work afterward.

e71t-gs gasless flux cored welding wire manufacturers

Applications

E71T-GS welding wire is frequently used in various industries and projects, including - Automotive Repair Due to its ability to weld thin materials and its portability, it’s a go-to for automotive enthusiasts and professionals alike. - Construction Ideal for structural welding, especially in field conditions where gas supplies may be impractical. - Fabrication Commonly used for fabricating metal structures and products, owing to its versatility on different types of metals. - Home Projects Hobbyists often use this wire for DIY projects, metal art, and repair work around the home.

Leading Manufacturers of E71T-GS Welding Wire

Various manufacturers specialize in producing high-quality E71T-GS gasless flux cored welding wire. Some of the most well-known brands include

1. Lincoln Electric A global leader in welding products that offers a variety of flux-cored wires, including E71T-GS, known for their reliability and performance. 2. Hobart Welding Products Popular among both professionals and DIY welders, Hobart produces high-grade welding wires that deliver exceptional results.

3. Forney Industries Known for their commitment to quality, Forney provides a selection of welding consumables that are widely used in multiple industries.

4. ESAB With a long-standing reputation in the welding industry, ESAB offers innovative welding solutions, including their own take on the E71T-GS wire.

Conclusion

E71T-GS gasless flux cored welding wire is a versatile and user-friendly material that caters to a wide range of welding applications. From professional industries to home projects, it provides ease of use, portability, and strong performance. With reputable manufacturers producing reliable E71T-GS wire, welders can find the right product that meets their specific needs, ensuring quality and satisfaction in every weld.

-

High-Performance Cellulose Electrode E6010 for Steel WeldingNewsJul.28,2025

-

High Quality E71T-11 Welding Wire from China – Flux Cored, Easy to UseNewsJul.28,2025

-

High-Quality SG2 Welding Wire for Superior PerformanceNewsJul.27,2025

-

E6011 Welding Rod for Arc Welding – High Performance & VersatilityNewsJul.26,2025

-

Welding Rod 2.0 mm for Structural Welding - High Strength & PrecisionNewsJul.25,2025

-

Factory Supply Cast Iron Welding Rods AWS ENi-CI High StrengthNewsJul.24,2025