electric welding wire manufacturers

The Electric Welding Wire Manufacturers Key Players in Modern Industry

Electric welding has revolutionized the manufacturing and construction industries, providing robust and reliable joining methods for various materials. A critical component of the welding process is the welding wire, which allows for the efficient and effective fusion of metals. As demand for diverse welding applications grows, so does the significance of electric welding wire manufacturers.

Understanding Welding Wire

Welding wire serves as the filler material in the welding process, and it comes in various forms such as solid wire, flux-cored wire, and tubular wire. Each type serves a specific purpose and choice is often dictated by the nature of the materials being welded and the desired characteristics of the weld. For instance, solid wires are commonly used in gas metal arc welding (GMAW), whereas flux-cored wires are more suited for applications in outdoor environments where shielding gases may disperse.

The Role of Manufacturers

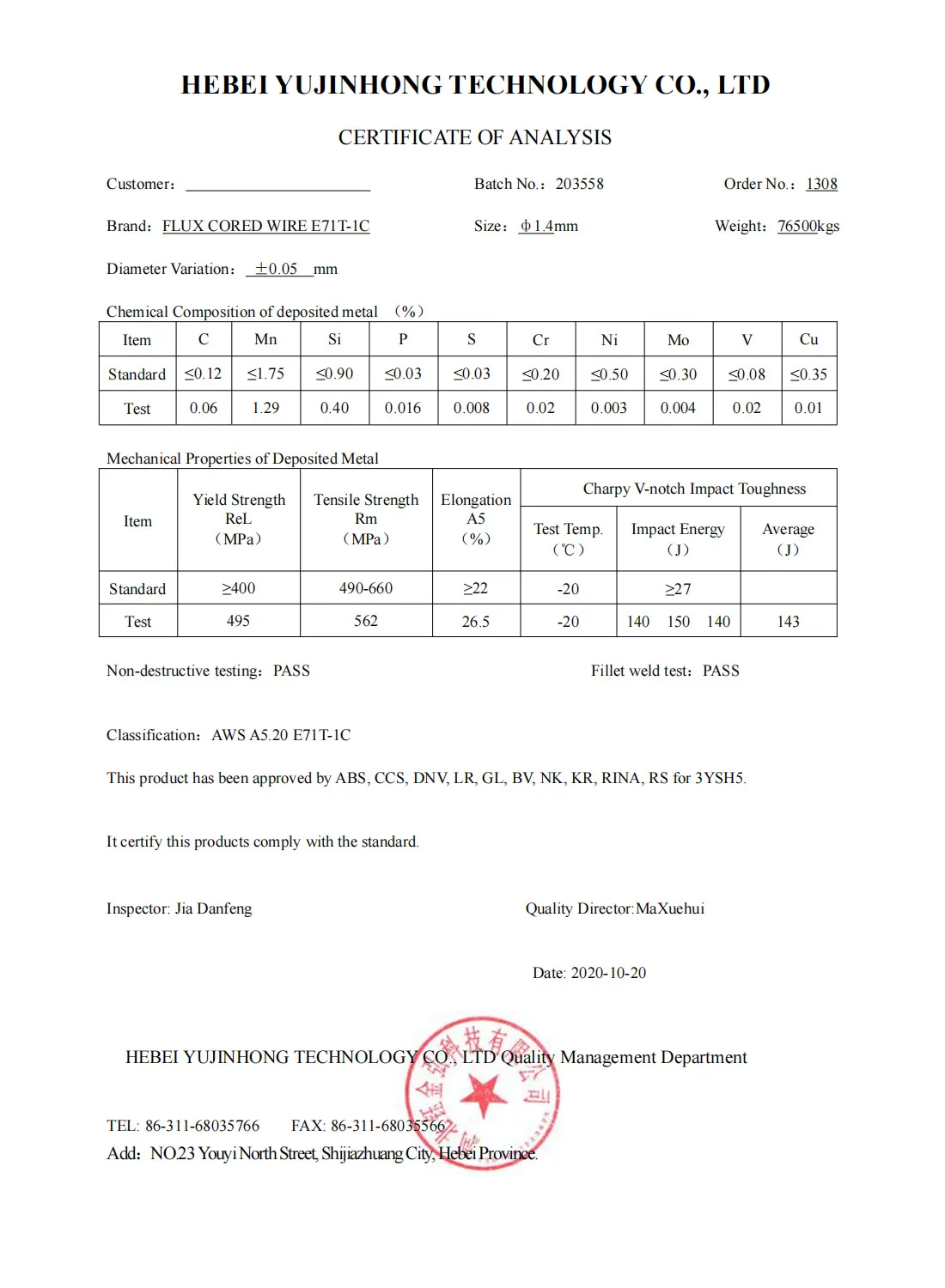

Electric welding wire manufacturers play a crucial role in the quality and reliability of welding operations. They are responsible for producing wires that meet stringent industry standards. This involves extensive research and development to innovate welding wire formulations that can withstand various stress factors, including temperature changes, corrosion, and mechanical stress.

These manufacturers utilize advanced technologies and high-grade materials to ensure their products exhibit excellent performance. They often conduct rigorous testing to evaluate the wires’ electrical conductivity, melting point, and fume generation. As a result, they actively contribute to enhancing safety and efficiency in welding processes.

Market Trends and Innovations

The electric welding wire market is influenced by several trends. One significant trend is the increasing demand for automation in welding processes. As industries adopt robotic welding systems for their accuracy and efficiency, manufacturers are adjusting their products to be compatible with these advanced technologies.

electric welding wire manufacturers

Another trend is the growing emphasis on sustainability. Manufacturers are exploring eco-friendly materials and production methods to reduce environmental impacts. This includes developing wires with reduced hazardous emissions and producing products that can be recycled or reused after their lifecycle.

Furthermore, the expansion of industries such as automotive, construction, and shipbuilding fuels demand for specialized welding wires. Manufacturers are focusing on creating wires that cater to specific industry needs, such as high-strength wires for automotive applications or corrosion-resistant wires for marine environments.

Leading Manufacturers in the Industry

Several brands are recognized as leaders in the electric welding wire manufacturing sector. Their contributions significantly impact the quality and evolution of welding technologies. Notable companies such as Lincoln Electric, ESAB, and Miller Electric are at the forefront, offering a wide range of welding products, including welding wires of varying compositions and characteristics.

These manufacturers not only produce standard welding wires but also develop customized solutions for their clients across different sectors. Their commitment to innovation ensures they remain competitive in a rapidly evolving market.

The Future of Electric Welding Wire Manufacturing

The future of electric welding wire manufacturing looks promising, driven by advancements in technology and an increasing focus on quality and performance. Manufacturers are likely to invest in enhancing their production capabilities through automation and artificial intelligence, ensuring faster turnaround times and maintaining high quality control standards.

As the welding industry evolves, manufacturers will continue to be key players in developing new products that meet the changing demands of their clients. With globalization, there may also be opportunities for these manufacturers to expand their markets internationally, increasing competition and variety for end-users.

In conclusion, electric welding wire manufacturers are essential to the integrity and progression of modern welding practices. Their commitment to quality, innovation, and sustainability will shape the future of welding, ensuring that it remains a cornerstone of manufacturing and construction across the globe. As industries continue to grow and evolve, the partnership between manufacturers and users will be pivotal in driving technological advancements and ensuring effective, safe, and sustainable welding solutions.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025