Manufacturing Processes for High-Quality Electrode Welding Sticks in Modern Factories

Exploring the Electrode Welding Sticks Factory A Gateway to Quality Welding Solutions

In the world of industrial manufacturing and construction, welding plays a pivotal role in ensuring the integrity and durability of structures and components. Electrode welding, in particular, is a popular method that employs various types of welding sticks to join metal pieces together. This article delves into the intricacies of an electrode welding sticks factory, highlighting the production process, quality control, and the significance of these essential tools in modern welding practices.

Understanding Electrode Welding Sticks

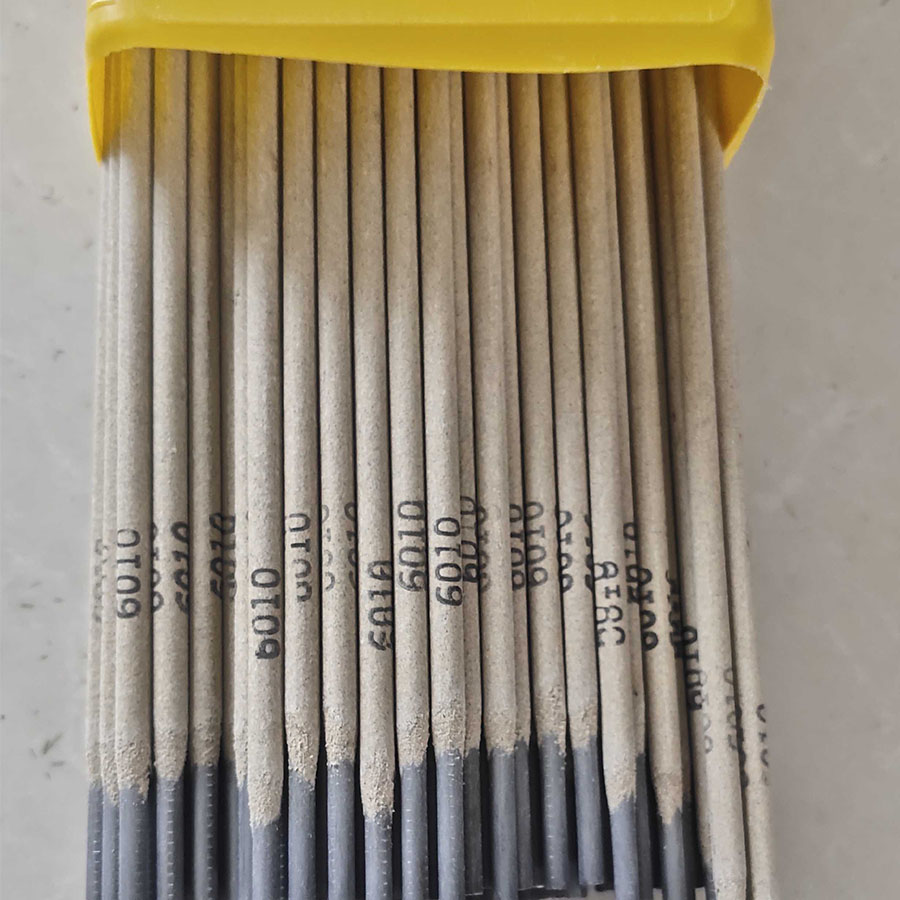

Welding electrodes are consumable materials made from metal, coated with flux, designed to conduct current and create a weld bead when heated. They come in various types, each tailored for specific welding applications—ranging from mild steel to stainless steel and even aluminum. The quality of these electrode welding sticks is crucial, as it directly impacts the strength, appearance, and overall success of the welding process.

The Production Process

The manufacturing of electrode welding sticks is a meticulous process that involves several key steps

1. Raw Material Selection The journey begins with the selection of high-grade raw materials, including metal powders, fluxes, and other additives. The choice of materials significantly influences the properties of the finished product, such as tensile strength, corrosion resistance, and melting point.

2. Mixing and Extrusion In this stage, the raw materials are carefully mixed to achieve a uniform consistency. The mixture is then extruded through a specially designed die to form the shape of the welding stick. This step ensures that each electrode has consistent dimensions, enhancing ease of use during the welding process.

electrode welding sticks factory

3. Drying and Coating Once extruded, the electrodes are subjected to drying processes to eliminate moisture. Following this, an additional coating of flux is applied, which plays a vital role in protecting the weld pool from contamination. This coating also aids in stabilizing the arc and improving the quality of the weld.

4. Quality Control Quality assurance is paramount in an electrode welding sticks factory. Each batch of products undergoes rigorous testing, including mechanical properties tests, chemical composition analysis, and visual inspections. This ensures that only the highest quality electrodes make it to the market.

The Importance of Quality Standards

Within the electrode welding industry, adherence to international quality standards is critical. Factories often implement ISO certifications and comply with other industry-specific regulations to ensure their products meet the necessary benchmarks. Not only do these standards help maintain quality, but they also foster trust among customers who rely on these electrodes for vital applications.

The Role of Technology

Advancements in technology have revolutionized the way electrodes are produced. Automation in manufacturing processes enhances precision and reduces production time, while innovations in materials science lead to the development of superior electrode formulations that exhibit better performance characteristics. Moreover, computer-aided design (CAD) tools enable manufacturers to innovate and customize their products to meet specific customer needs.

Conclusion

The electrode welding sticks factory stands as a testament to the blend of traditional craftsmanship and modern technology. These factories produce essential tools that are foundational to the welding industry. As the demand for quality welding solutions continues to rise, the significance of efficient production and quality control in electrode welding sticks manufacturing will only grow. Investing in high-quality electrodes not only enhances the durability and aesthetics of welds but also ensures operational efficiency in various industrial applications.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025