Top Manufacturers of A/C Welding Rods in the Industry

The Significance of A/C Welding Rod Manufacturers in the Industry

Welding is a critical process in various industries, from construction to automotive manufacturing. It joins materials together using high heat, and one of the essential components in this process is the welding rod. Among the various types of welding rods available, A/C welding rods are particularly important for many applications. This article explores the role of A/C welding rod manufacturers and their significance in the welding industry.

Understanding A/C Welding Rods

A/C welding rods are designed for arc welding processes that rely on alternating current. These rods are often used for welding ferrous metals and are known for their ability to produce strong and durable welds. Due to their versatility, A/C welding rods are popular in various applications, including structural welding, pipeline construction, and maintenance operations. As a result, the demand for high-quality A/C welding rods has surged, necessitating the need for specialized manufacturers.

The Role of A/C Welding Rod Manufacturers

A/C welding rod manufacturers play a vital role in the welding industry. They are responsible for producing rods that meet industry standards and specifications, ensuring that they perform optimally in various welding applications. These manufacturers invest in research and development to innovate new products that enhance welding efficiency, reduce spatter, and improve overall weld quality.

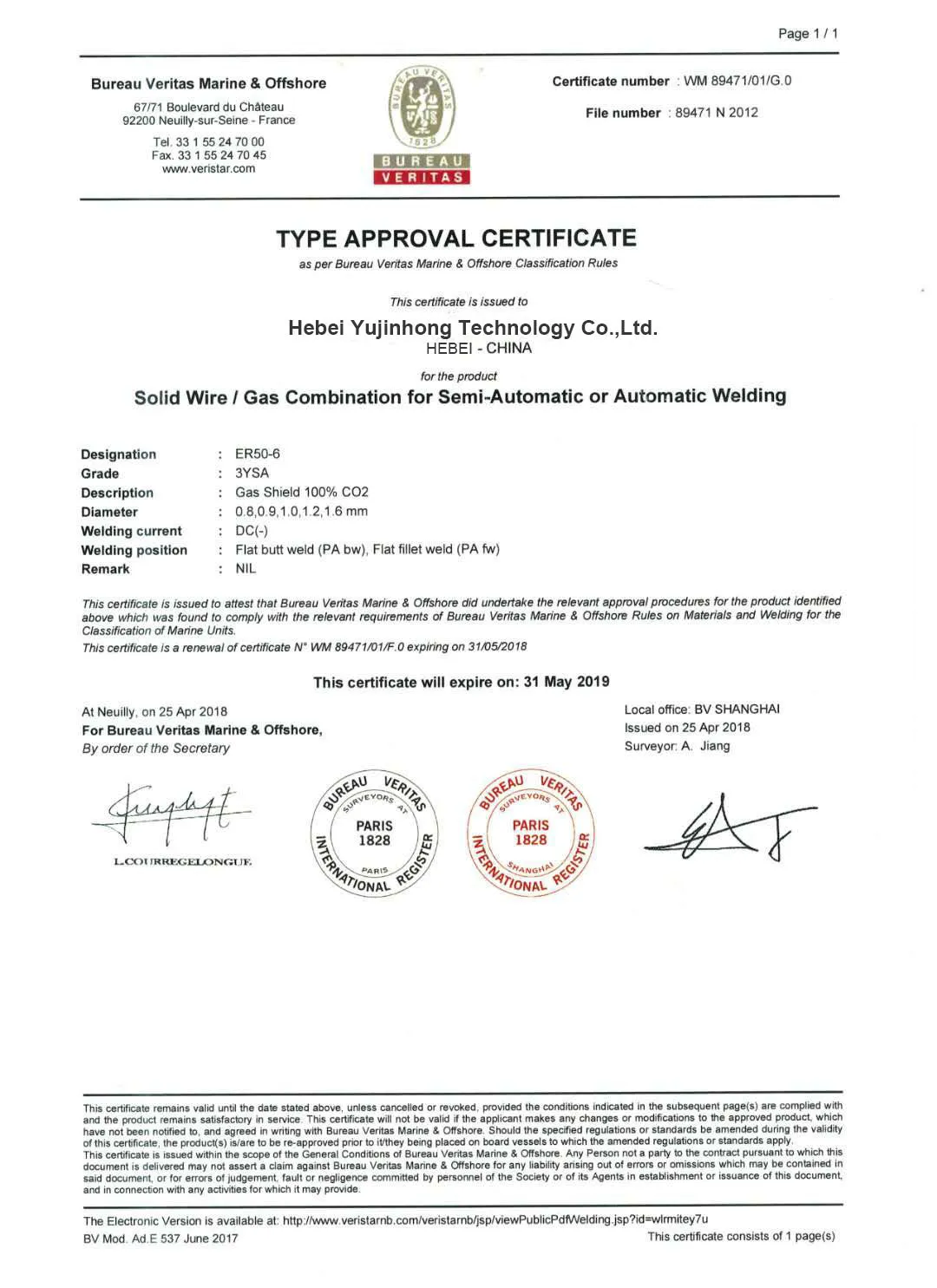

One of the primary responsibilities of A/C welding rod manufacturers is to ensure consistency in their products. Quality control measures are implemented throughout the manufacturing process to meet stringent performance guidelines. The use of high-quality raw materials, along with advanced manufacturing techniques, allows these companies to produce welding rods that deliver reliable results. Manufacturers often provide detailed specifications and certifications for their products, which helps welders make informed choices based on their specific needs.

Customization and Technological Advancements

a/c welding rod manufacturers

As technology continues to evolve, so do the demands of the welding industry. A/C welding rod manufacturers are increasingly focusing on customization to cater to various industry requirements. They are capable of producing rods tailored to specific applications, including rods with enhanced corrosion resistance, improved mechanical properties, and compatibility with different base metals.

Moreover, advancements in manufacturing technologies, such as automation and computer-aided design, have significantly improved the precision and efficiency of welding rod production. These innovations help reduce lead times and ensure that manufacturers can quickly respond to market demands. Additionally, eco-friendly manufacturing practices are becoming more prevalent as companies strive to minimize their environmental impact.

Market Trends and Future Outlook

The global welding industry is projected to grow in the coming years, driven by increased infrastructure development, automotive production, and the rise of renewable energy sources. This growth will undoubtedly lead to increased demand for A/C welding rods, providing opportunities for manufacturers to expand their operations and innovate further.

A/C welding rod manufacturers must also keep an eye on market trends, such as the growing need for lightweight materials in construction and automotive applications. As industries shift to more sustainable practices, manufacturers that can offer eco-friendly products and meet the evolving standards will likely have a competitive edge.

Conclusion

In conclusion, A/C welding rod manufacturers are essential players in the welding industry, providing high-quality products that ensure strong, reliable welds across various applications. Their commitment to quality, innovation, and customer satisfaction will continue to drive the industry forward. As the demand for advanced welding solutions grows, these manufacturers will play a pivotal role in shaping the future of welding, making them integral to the ongoing development of engineering and manufacturing processes.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025