High-Quality MIG Welding Wire for Wholesale Use in Various Applications

The Importance of Wholesale MIG Welding Wire A Comprehensive Guide

MIG (Metal Inert Gas) welding has become a cornerstone of modern manufacturing and construction. This process relies heavily on the use of high-quality welding wire, which significantly impacts the efficiency, performance, and overall cost of welding operations. Among the many available products, wholesale MIG welding wire stands out as a vital resource for companies looking to streamline their operations while ensuring superior weld quality.

Understanding MIG Welding

MIG welding is a semi-automatic or automatic welding process that uses a continuous solid wire electrode, which is fed through a welding gun. An inert gas, typically argon or a mix of argon and carbon dioxide, shields the molten weld pool from atmospheric contamination. This process is well-regarded for its speed and versatility, making it suitable for various applications ranging from automotive manufacturing to construction projects.

The Benefits of Using Wholesale MIG Welding Wire

1. Cost Efficiency One of the most significant advantages of purchasing MIG welding wire in bulk is the cost savings. Wholesale prices are generally lower than retail prices, allowing businesses to reduce their operational costs. By purchasing in larger quantities, companies can benefit from lower prices per unit, thus maximizing their profit margins.

2. Consistency in Quality When sourcing MIG welding wire from a reputable wholesale supplier, companies can ensure a consistent quality of materials used for welding. Quality welding wire is essential for creating strong, durable welds that can withstand stress and environmental factors. Inconsistent weld quality can lead to defects, costly reworks, and compromised safety.

3. Availability of Variety Wholesale suppliers typically offer a wide range of MIG welding wires, catering to different needs and specifications. This includes variations in diameter, alloy composition, and coating types, allowing businesses to select the most suitable wire for their specific applications. Whether it’s for welding mild steel, stainless steel, or aluminum, wholesale suppliers can accommodate diverse welding requirements.

4. Improved Supply Chain Management Establishing a relationship with a wholesale MIG welding wire supplier can significantly enhance supply chain efficiency. Companies can plan their inventory more effectively, reducing the risk of running out of materials during critical projects. This proactive approach minimizes downtime and ensures that production schedules remain on track.

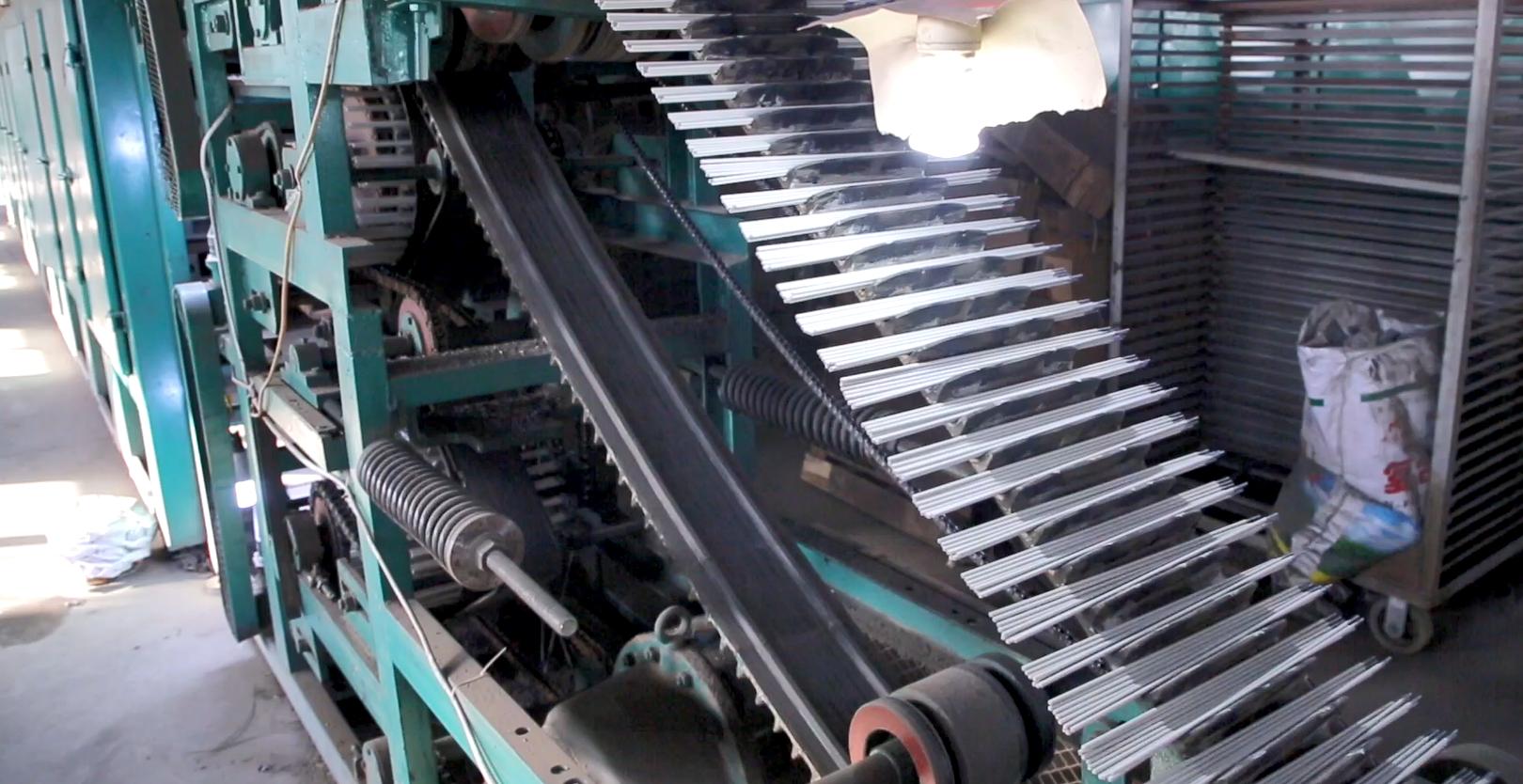

wholesale mig welding wire 0.7

5. Expert Support and Guidance Many wholesale suppliers have extensive knowledge of welding materials and techniques. By partnering with these suppliers, companies can gain access to valuable insights about selecting the right welding wire and optimizing their welding processes. This support can be instrumental in improving overall welding performance and achieving better results.

Choosing the Right Wholesale Supplier

When selecting a wholesale MIG welding wire supplier, business owners should consider several key factors

- Reputation Look for suppliers with a proven track record for delivering high-quality products. Customer reviews and testimonials can provide insight into their reliability and service levels. - Product Range Ensure that the supplier offers a comprehensive range of MIG welding wires suited for various applications, including specialty wires that meet specific industrial standards.

- Customer Service A good supplier should provide excellent customer support, assisting with order inquiries, technical questions, and any issues that may arise.

- Shipping and Delivery Evaluate the supplier’s shipping policies. Timely delivery is crucial for maintaining production schedules and managing inventory effectively.

Conclusion

In summary, wholesale MIG welding wire is an integral component of successful welding operations across various industries. By understanding the benefits and making informed choices when selecting a supplier, companies can enhance their welding processes, reduce costs, and improve overall product quality. The right wholesale supplier can be a valuable partner in achieving these goals, providing not only materials but also expertise and support for continuous improvement in welding operations. As the demand for quality welding continues to rise, investing in wholesale MIG welding wire is a strategic decision that can drive success in any welding project.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025