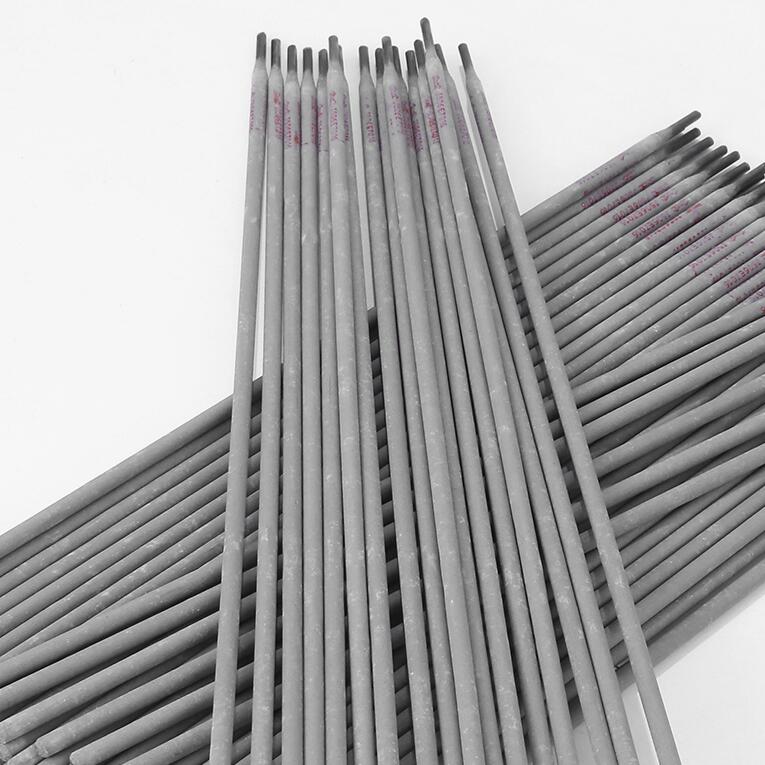

wholesale submerged welding wire factory

The Role of Wholesale Submerged Welding Wire Factories in Modern Manufacturing

In the ever-evolving landscape of manufacturing, the importance of high-quality welding materials cannot be overstated. One critical component that plays a significant role in various industrial applications is submerged welding wire. Wholesale submerged welding wire factories have become essential players in the supply chain, providing manufacturers with the necessary materials for efficient and effective welding operations.

Submerged arc welding (SAW) is a highly productive welding process that creates a weld by forming an electric arc between the workpiece and a continuously fed electrode wire, which is submerged under a blanket of granular fusible flux. This method is widely employed in fabricating thick plates and components used in the construction and manufacturing of shipbuilding, bridge construction, and large structural assemblies. A key factor in the success of this welding process is the quality of the welding wire itself.

Wholesale submerged welding wire factories are dedicated to producing high-grade welding wires that meet various industry standards. These factories utilize advanced technology and processes to ensure that their products are reliable, consistent, and capable of withstanding the rigors of industrial applications. The production of submerged welding wire involves careful selection of raw materials, precision engineering, and rigorous testing to guarantee the wire's performance in various welding environments.

The benefits of sourcing submerged welding wire from wholesale factories are multifaceted. First and foremost is cost-effectiveness. By purchasing in bulk, manufacturers can significantly reduce their per-unit costs. Wholesale factories often provide competitive pricing due to their large-scale production capabilities. This cost advantage is crucial for businesses looking to maintain profitability while ensuring high-quality output.

wholesale submerged welding wire factory

Moreover, wholesale factories can offer a wider variety of submerged welding wires that cater to different welding needs. From mild steel to high-strength steel alloys, these factories provide options for various applications. This flexibility allows manufacturers to select the most suitable wire for their specific projects, thereby enhancing the overall quality of the welds produced.

Another significant advantage of partnering with wholesale submerged welding wire factories is the ability to establish a reliable supply chain. Consistency in the quality and availability of welding materials is vital for maintaining production schedules. Wholesale vendors typically have robust inventory management systems that ensure manufacturers can procure the required materials in a timely manner, minimizing downtime and maximizing productivity.

In addition to these operational benefits, many wholesale factories prioritize sustainability in their manufacturing processes. As industries face increasing pressure to reduce their environmental impact, manufacturers are seeking suppliers that align with their sustainability goals. Many submerged welding wire factories are adopting eco-friendly practices, such as optimizing resource use, reducing waste, and implementing recycling programs. This commitment to sustainability not only helps the environment but also enhances the reputation of both the manufacturers and suppliers involved.

Quality assurance is a cornerstone of success in the welding industry, and reputable wholesale submerged welding wire factories often provide detailed certifications and documentation for their products. These certifications give manufacturers peace of mind, ensuring that the materials they are using meet required safety and performance standards. This transparency is crucial, especially in industries where the integrity of welded components is paramount.

In conclusion, wholesale submerged welding wire factories play a pivotal role in modern manufacturing, offering a reliable source of high-quality welding materials. Their ability to provide cost-effective solutions, diverse product offerings, and a commitment to sustainability positions them as key partners for manufacturers across various industries. As the demand for efficient and reliable welding solutions continues to grow, the importance of these factories will undoubtedly remain significant in the years to come. Ensuring quality and reliability in welding processes starts with sourcing the best materials from trusted wholesale suppliers.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025