Top Suppliers for MIG Welding Wire and Equipment Solutions

Exploring Wire Welding MIG Suppliers and Their Impact on Industry

Wire welding has become an essential process in various manufacturing and fabrication industries, particularly in the realm of metalworking. The Metal Inert Gas (MIG) welding technique is one of the most preferred methods due to its versatility, efficiency, and quality of welds. This article will delve into the significance of wire welding, highlight key MIG suppliers, and outline the factors that businesses should consider when selecting a supplier.

Understanding MIG Welding

MIG welding, also known as Gas Metal Arc Welding (GMAW), utilizes a continuous feed of metal wire as an electrode, which is fed through a welding gun and melted to join two pieces of metal together. This process is favored for its speed and ease of operation, making it ideal for both novice and experienced welders. The method also allows for the use of various materials, including stainless steel, aluminum, and carbon steel, which broadens its application across multiple sectors such as automotive, construction, and shipbuilding.

The Role of Suppliers in Wire Welding

The effectiveness of MIG welding is influenced significantly by the quality of the wire and associated supplies. As a result, selecting a reliable MIG supplier is crucial. Quality suppliers offer a range of products, including welding wires, gas mixes, and welding machines, all of which must meet specific industry standards for performance and safety.

Leading MIG suppliers not only provide high-quality products but also offer expertise and support to their customers. They often collaborate with manufacturers to ensure that the latest technologies are integrated into their offerings, thereby enhancing the overall welding process.

Notable MIG Suppliers

Some of the renowned MIG welding suppliers include

1. Lincoln Electric Known for their innovative welding technology, Lincoln Electric offers a variety of MIG welding machines and wires, ensuring quality and reliability in every application. Their extensive product line caters to various industries and skill levels.

2. Miller Electric Miller is recognized for its user-friendly MIG welding machines that incorporate advanced features like Auto-Set technology. They provide a broad selection of welding wires suitable for many different metals.

3. ESAB A leading supplier of welding and cutting equipment, ESAB boasts a diverse portfolio that includes MIG welding wires. Their products are designed for optimum performance, catering to both heavy-duty and precision applications.

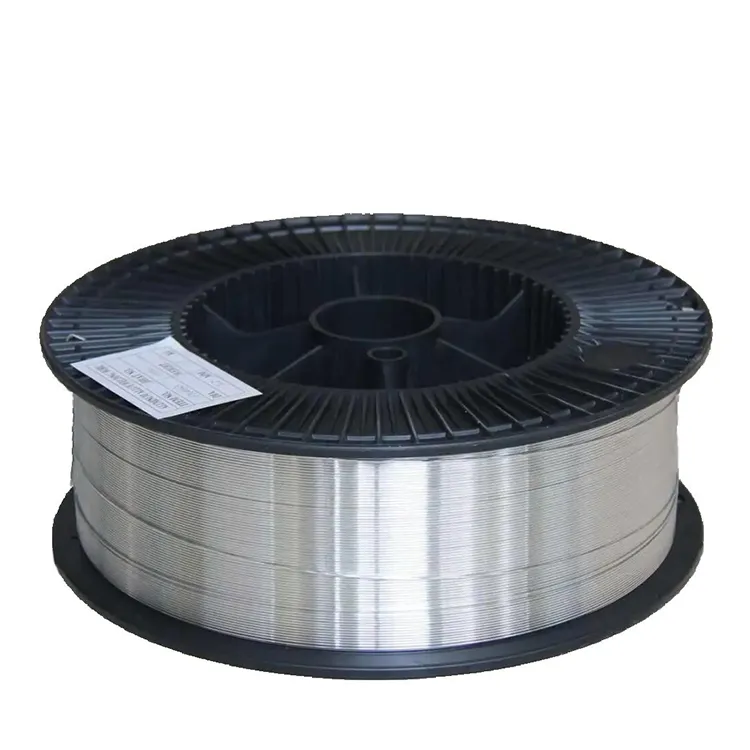

wire welding mig suppliers

4. Hobart Brothers Hobart specializes in manufacturing welding wires and electrodes that deliver exceptional performance. Their dedication to quality and innovation makes them a popular choice among industry professionals.

5. Ameriflux This supplier focuses specifically on high-performance welding wires and is known for robust support services. They cater to niche markets requiring specialized wire formulations.

Factors to Consider When Choosing a MIG Supplier

When looking for a MIG welding supplier, businesses should evaluate the following factors

1. Quality of Materials The integrity and performance of welding wires directly impact the quality of the weld. A supplier should provide materials that meet or exceed industry standards.

2. Product Range Consider suppliers that offer a comprehensive portfolio, including various types of welding wires for different applications, as well as equipment and accessories.

3. Technical Support Access to knowledgeable customer service and technical support can make a significant difference in ensuring the correct application of products and troubleshooting issues.

4. Reputation and Reviews Researching a supplier's reputation in the industry through customer reviews and case studies can provide insights into their reliability and the quality of their products.

5. Pricing While cost is an important factor, it should not be the sole consideration. Evaluating the overall value, which includes product quality, support, and service, is crucial for long-term satisfaction.

Conclusion

Wire welding, particularly MIG welding, plays a vital role in the modern manufacturing landscape. Selecting a reputable MIG supplier can significantly enhance productivity and the quality of welded products. As industries continue to evolve, the need for reliable suppliers offering advanced materials and equipment will only grow. Businesses should take the time to research and choose suppliers that will contribute positively to their operations and ensure the success of their welding processes.

-

Premium Stainless TIG Electrodes High-Quality Welding SolutionsNewsMay.21,2025

-

E6013 3/32 Electrodes Wholesale Manufacturers - Durable & AffordableNewsMay.21,2025

-

E71TGS Welding Wire High-Strength Flux Core for Durable JointsNewsMay.20,2025

-

High-Strength 3/4 Welding Rod 7016 for Pipe Welding China SupplierNewsMay.20,2025

-

71T1 Flux Cored Wire High-Performance 1.2mm Welding SolutionsNewsMay.20,2025

-

3.25mm Welding Electrodes High-Performance, Durable Wholesale FactoryNewsMay.19,2025