0.8mm MIG Wire for Reliable Welding Performance and Quality Results

Understanding MIG Welding with 0.8mm Wire A Comprehensive Overview

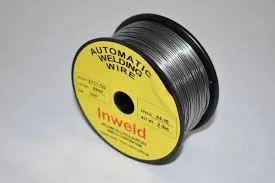

MIG welding, or Metal Inert Gas welding, is a popular welding process that utilizes a continuous feed of consumable wire as the electrode. One of the most commonly used wire diameters in MIG welding is 0.8mm. This article will explore the significance of 0.8mm MIG wire, its applications, advantages, and how to select the right wire for various welding tasks.

What is MIG Welding?

MIG welding is a type of arc welding that employs a wire electrode fed through a welding gun. The wire melts and joins the base metals together as a result of the heat generated by an electric arc between the wire and the workpiece. An inert gas, usually argon or a mix of argon and carbon dioxide, shields the molten weld pool from contaminants in the atmosphere, ensuring a clean and strong weld.

The Importance of 0.8mm Wire

The diameter of MIG wire plays a crucial role in the welding process. A 0.8mm wire is lightweight, which makes it particularly suitable for welding thin materials, usually within the range of 1mm to 6mm thickness. This size is commonly chosen for applications like automotive bodywork, sheet metal fabrication, and other precision welding tasks. The fine diameter enables a better control of the heat input and minimizes distortion, which is critical when working with delicate materials.

Applications of 0

.8mm MIG Wire1. Automotive Industry In automotive fabrication and repairs, 0.8mm wire is frequently utilized for welding sheets and components. The thin gauge allows welders to join metals without significantly affecting the overall integrity of the parts.

2. Home Projects Hobbyists and DIY enthusiasts often prefer 0.8mm wire for projects involving metal art, furniture construction, or crafting prototypes. Its ease of use and versatility make it an excellent choice for various home welding tasks.

3. Metal Fabrication In commercial settings, manufacturers often employ 0.8mm wire for fabricating lightweight structures and components. Its ability to provide a clean weld with minimal spatter enhances the efficiency of production processes.

Advantages of Using 0.8mm MIG Wire

mig wire 0.8mm

- Precision The smaller diameter allows for precise control when welding, resulting in clean and neat welds that require less finishing.

- Less Heat Input With a 0.8mm wire, the heat input can be carefully managed, reducing the risk of warping or burning through thinner materials.

- Versatility This wire size is suitable for a variety of materials, including mild steel, stainless steel, and aluminum, making it a versatile choice for many applications.

- Ease of Use For both beginners and experienced welders, 0.8mm wire is relatively easy to handle and feeds smoothly through welding machines, which enhances the overall welding experience.

Choosing the Right MIG Wire

When selecting MIG wire, it’s essential to consider the specific requirements of your project. Factors to consider include

- Material Type Different materials may require different wire compositions (e.g., ER70S-6 for mild steel).

- Thickness of Base Metals Ensure the selected wire diameter is appropriate for the thickness of the materials being welded. For thinner sheets, 0.8mm is ideal.

- Welding Position The welding position can affect the choice of wire; for overhead and vertical welding, a smaller diameter can provide better control.

Conclusion

In conclusion, 0.8mm MIG wire is an invaluable tool for various welding applications, especially when working with thin materials. Its precision, versatility, and ease of use make it a popular choice among professionals and amateurs alike. Whether in automotive repair, home projects, or fabrication tasks, understanding the benefits and proper use of 0.8mm MIG wire can lead to superior welding results and enhanced overall project quality.

-

Premium AC Stainless Steel Welding Rods - Durable & Corrosion-ResistantNewsAug.05,2025

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025