aluminum welding rod factory

The Importance of Aluminum Welding Rod Factories

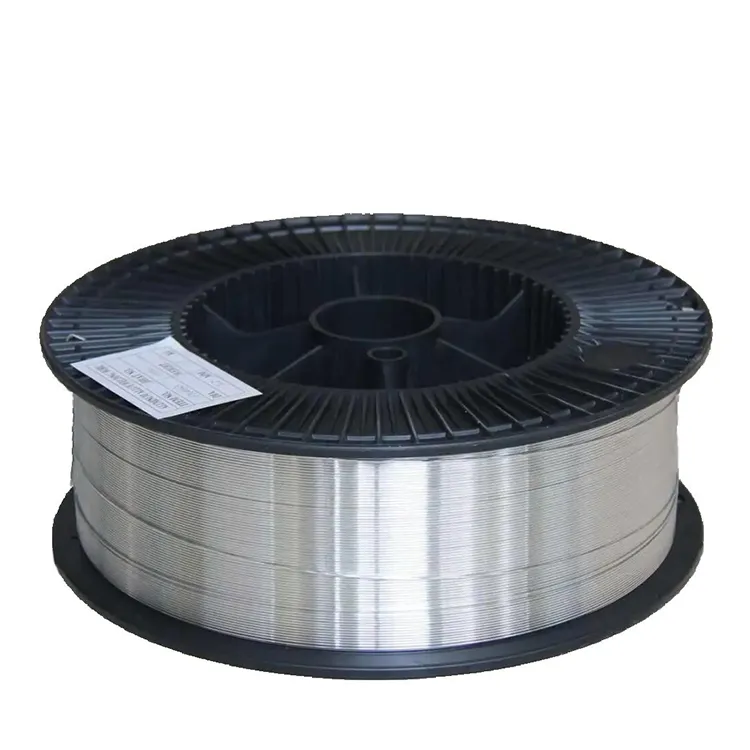

In the realm of modern manufacturing and construction, aluminum has emerged as a material of choice due to its remarkable properties, such as light weight, high strength, and excellent corrosion resistance. However, the welding of aluminum presents unique challenges that require specialized techniques and materials. One of the most critical components in the welding process is the aluminum welding rod, produced by dedicated factories that focus on manufacturing high-quality welding supplies.

Aluminum welding rods come in various compositions to suit different types of aluminum alloys. These rods are essential for processes like TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding, which are widely used in various industries, including automotive, aerospace, and construction. The quality of the welding rod directly affects the integrity and durability of the weld, making it paramount that factories adhere to stringent quality control measures during production.

An aluminum welding rod factory typically employs advanced technology and skilled labor to produce rods that meet industry standards. The process begins with the selection of high-purity aluminum and alloying elements, which are melted and mixed to create a homogeneous material. This mixture is then extruded into rod form and cut to specified lengths. Manufacturers must ensure that the rods exhibit excellent mechanical properties and optimal melting characteristics to facilitate smooth welding operations.

aluminum welding rod factory

One of the crucial aspects of a successful aluminum welding rod factory is its ability to innovate. With advancements in welding technology, factories need to stay at the forefront of research and development to design rods that improve the efficiency and quality of welding processes. This can involve creating rods with special coatings to enhance performance or developing new alloys that provide better compatibility with various base materials.

Sustainability is also a growing concern in the manufacturing sector. Many aluminum welding rod factories are striving to minimize their environmental impact by adopting eco-friendly practices. This includes recycling aluminum scrap generated during production and using energy-efficient manufacturing processes. By prioritizing sustainability, these factories contribute to a greener future while also appealing to environmentally conscious consumers.

Another vital component of an aluminum welding rod factory's operation is customer support. Providing technical assistance and guidance to clients helps ensure that the right products are used for specific applications. Training programs, product demonstrations, and expert consultations play an essential role in helping customers optimize their welding processes.

In conclusion, aluminum welding rod factories play a crucial role in the manufacturing industry by producing high-quality materials that are essential for effective aluminum welding. As technology advances and sustainability becomes more important, these factories must adapt to meet changing demands while ensuring their products maintain the high standards required for successful welding applications. By doing so, they not only support the industries that rely on aluminum but also contribute to the overall efficiency and sustainability of modern manufacturing.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025