Aluminum MIG Welding Wire Production Facility for High-Quality Welding Solutions

The Rise of Aluminum MIG Welding Wire Factories

In the evolving landscape of manufacturing and metalworking, aluminum MIG (Metal Inert Gas) welding has emerged as a pivotal technology. The demand for aluminum components in various industries, including automotive, aerospace, and construction, has led to a significant increase in the production of aluminum MIG welding wire. As a result, aluminum MIG welding wire factories are playing a crucial role in meeting this demand.

Aluminum is favored in manufacturing due to its lightweight, corrosion resistance, and excellent conductivity. However, welding aluminum requires specialized techniques and materials to ensure strong, durable joints. This is where aluminum MIG welding wire comes into play. These wires are designed specifically for welding aluminum, allowing for efficient and high-quality welds.

The Rise of Aluminum MIG Welding Wire Factories

Quality control is paramount in the production of aluminum MIG welding wire. Rigorous testing and inspection processes are implemented throughout the manufacturing cycle to guarantee that the final product meets industry standards. Parameters such as wire diameter, tensile strength, and corrosion resistance are meticulously monitored. This commitment to quality ensures that welders can rely on the wires to perform consistently under demanding conditions.

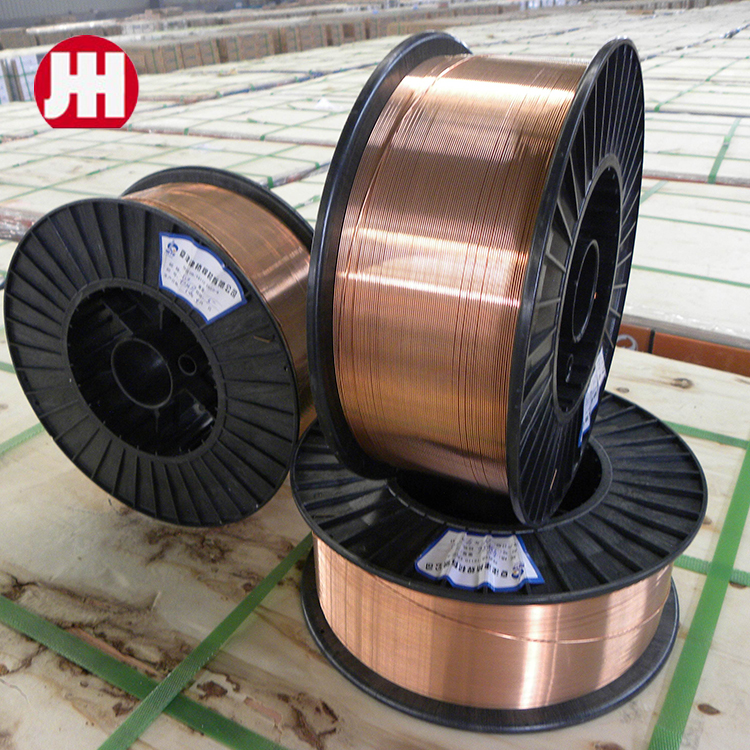

aluminum mig welding wire factory

The growth of aluminum MIG welding wire factories is also propelled by the increasing trend towards lightweight structures and energy-efficient designs. Industries are now prioritizing materials that contribute to sustainability, allowing aluminum to shine as a top choice. Consequently, there is a burgeoning market for aluminum welding supplies as manufacturers strive to develop lighter yet stronger products.

Furthermore, with the ongoing advancements in welding technology, the future of aluminum MIG welding wire manufacturing looks promising. Factories are investing in research and development to innovate new wire formulations and improve welding processes. This not only enhances the performance of aluminum welding wires but also reduces waste and increases operational efficiency.

The globalization of the market has also spurred the growth of aluminum MIG welding wire factories. Manufacturers are able to access a broader customer base and cater to diverse needs across different regions. This expansion creates opportunities for collaboration and partnerships, further advancing the capabilities of welding technology.

In conclusion, aluminum MIG welding wire factories are integral to the modern manufacturing ecosystem. Their ability to produce high-quality welding wires supports the growing demand for aluminum in various sectors. As technology continues to advance and industries seek more effective solutions, these factories will undoubtedly play a pivotal role in shaping the future of welding and metal fabrication.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025