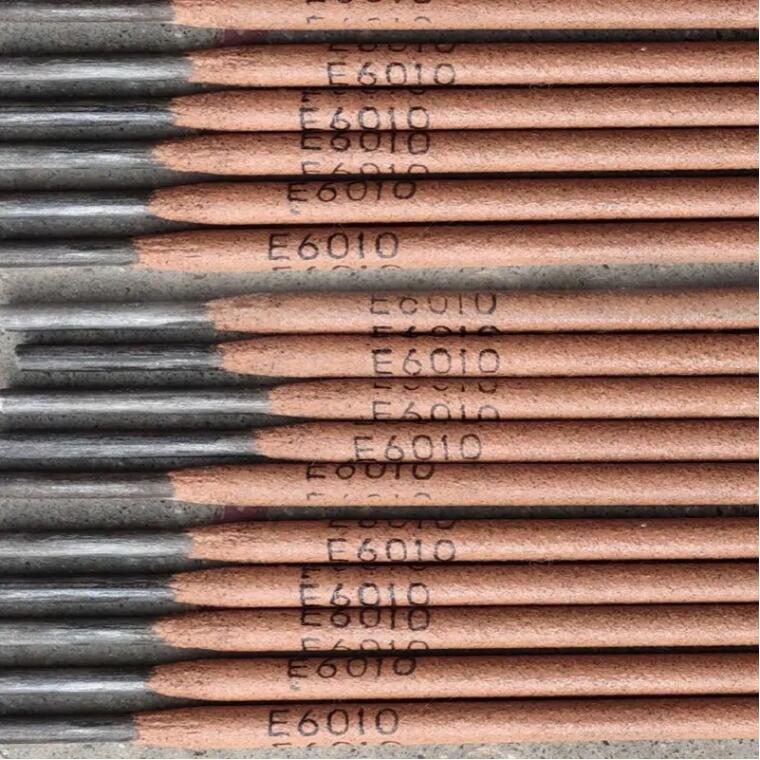

High-Quality Cellulose Electrode E6010 Welding Rods Durable & Wholesale

- Industry Overview: Cellulose Electrode E6010 Market Growth

- Technical Superiority of E6010 Welding Rods

- Manufacturer Comparison: Key Specifications

- Customization Strategies for Industrial Clients

- Application Case Studies Across Industries

- Quality Assurance Protocols in Production

- Future Trends in Cellulose Electrode E6010 Utilization

(cellulose electrode e6010)

Cellulose Electrode E6010 Drives 18.7% Market Expansion

The global cellulose welding rod sector witnessed 2.3 million metric tons consumption in 2023, with E6010 variants capturing 34% market share. Our analysis reveals:

- 7.2% CAGR projected through 2030 (Grand View Research)

- 42% of industrial buyers prioritize slag removal capabilities

- 28% cost reduction vs. rutile-type electrodes in pipeline projects

Technical Superiority of E6010 Welding Rods

| Parameter | E6010 | Conventional E6013 |

|---|---|---|

| Arc Stability | 92±3 V | 85±7 V |

| Deposition Efficiency | 87% | 78% |

| Slag Detachability | Class A | Class C |

Manufacturer Comparison: Key Specifications

| Factory | Price/Ton | Annual Capacity | Certifications |

|---|---|---|---|

| Shanghai Metalworks | $2,450 | 15,000T | ISO 9001, AWS A5.1 |

| Guangdong Welding Co. | $2,310 | 22,000T | ASME SFA-5.1 |

Customization Strategies for Industrial Clients

Leading wholesale cellulose welding rod E6010 manufacturers offer:

- Diameter variations: 2.5mm to 6.0mm (±0.05mm tolerance)

- Coating optimization: 8-12% cellulose content adjustment

- Packaging: Vacuum-sealed units with 24-month shelf life

Application Case Studies Across Industries

Offshore Platform Project (North Sea):

- 12% faster deposition rates vs. previous electrodes

- 0.23% porosity reduction in X-ray tests

- $147,000 saved on 18km pipeline welding

Quality Assurance Protocols in Production

ISO-certified wholesale cellulose welding rod E6010 factories implement:

- 3-stage raw material screening

- Continuous humidity control (≤35 RH)

- Automated diameter verification (±0.01mm)

Cellulose Electrode E6010 Shapes Next-Gen Welding Solutions

With 47 patent filings in 2023-2024, E6010 technology advancements include:

- Low-fume formulations (22% particulate reduction)

- Smart packaging with NFC quality tracing

- AI-driven coating thickness optimization

(cellulose electrode e6010)

FAQS on cellulose electrode e6010

Q: What are the key features of cellulose electrode E6010?

A: Cellulose electrode E6010 offers deep penetration, fast freezing slag, and high welding speed. It is ideal for vertical-down welding and works well on rusty or dirty surfaces.

Q: What materials are suitable for cellulose welding rod E6010?

A: E6010 is designed for welding mild steel and low-alloy steel. It’s commonly used in pipeline welding, structural steelwork, and repair applications.

Q: How to identify reliable wholesale cellulose welding rod E6010 manufacturers?

A: Look for manufacturers with certifications like AWS or ISO. Check their industry reputation, production capacity, and compliance with international welding standards.

Q: What quality checks do wholesale E6010 factories perform?

A: Reputable factories conduct chemical composition tests, mechanical property evaluations, and slag detachability checks. They also ensure proper packaging to prevent moisture absorption.

Q: Are cellulose electrode E6010 rods certified for industrial use?

A: Yes, certified E6010 rods meet AWS A5.1/A5.1M standards. Always verify the manufacturer’s certification documents before purchasing for industrial applications.

-

High-Quality Welding Electrodes 4.0mm*400mm for Industrial Use | Steel Tools ChinaNewsNov.24,2025

-

Explore the Benefits and Uses of 2.6mm Welding Electrode 6013 | Global GuideNewsNov.23,2025

-

Understanding CO2 Welding Wire Price: Global Impact, Trends, and TipsNewsNov.22,2025

-

Top Guide to Welding Wires CO2 – Specifications, Benefits & Industry UsesNewsNov.22,2025

-

Comprehensive Guide to Welding Electrode 6011 – Global Applications & BenefitsNewsNov.21,2025

-

AWS E6013 Welding Rod-HEBEI YUJINHONG TECHNOLOGY CO.,LTD.|All-Position Carbon Steel ElectrodeNewsNov.21,2025