Suppliers of Flux Core Welding Wire for Chinese Markets and Industries

Understanding Suppliers of China Flux Core Welding Wire

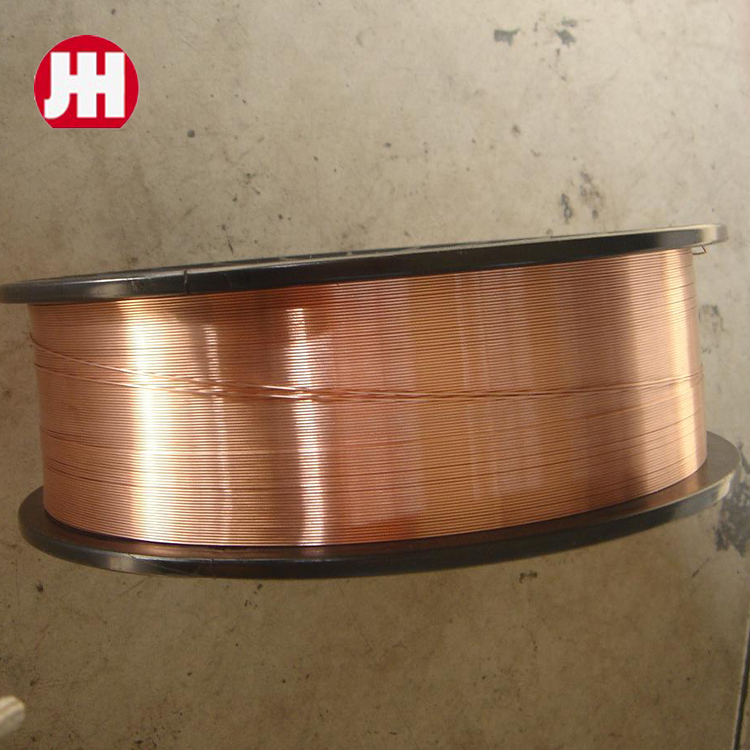

When it comes to welding, selecting the right materials is pivotal for achieving high quality and durable welds. Among various welding materials, flux-cored welding wire has gained significant popularity due to its efficiency and versatility. This article delves into the suppliers of flux core welding wire in China, exploring the benefits, applications, and what to consider when sourcing these materials.

What is Flux Core Welding Wire?

Flux core welding wire is a type of welding wire that contains a flux within it. This flux serves multiple purposes such as shielding the weld pool from contamination, allowing for better penetration in thicker materials, and improving the overall weld quality. The two main types of flux-cored welding wires are gas-shielded and self-shielded. Each type caters to different welding environments and applications.

Benefits of Using Flux Core Welding Wire

1. Versatility Flux core welding wire is suitable for a variety of materials, including stainless steel, carbon steel, and low-alloy steel. This makes it an excellent choice for many industries, including construction, manufacturing, and automotive.

2. Speed and Efficiency One of the most significant advantages of using flux-cored wire is the speed of the welding process. It allows for higher deposition rates and can be used in all positions, which can enhance productivity on the job.

3. Less Sensitivity to Wind Unlike traditional MIG welding that requires shielding gas, self-shielded flux-cored wire can be used outdoors without being affected by wind. This is particularly advantageous for construction projects exposed to outdoor conditions.

4. High Penetration Capability Flux core welding wire can penetrate thick materials more effectively compared to some other welding processes, reducing the likelihood of weak welds in thicker workpieces.

Choosing the Right Supplier in China

When sourcing flux core welding wire from suppliers in China, several factors should be considered to ensure quality and reliability

1. Quality Certification

china flux core welding wire suppliers

One must look for suppliers that have necessary certifications, such as ISO 9001 or certifications from international welding standards organizations

. These certifications are indicators of the suppliers’ commitment to quality and manufacturing excellence.2. Product Range

It is crucial to partner with suppliers who offer a broad range of flux-cored welding wires. Different welding applications require different types of wires, including varied diameters, flux compositions, and post-weld characteristics.

3. Technical Support

A good supplier should offer technical support to help customers choose the right products for their specific needs. This includes advice on welding parameters, equipment compatibility, and troubleshooting.

4. Reputation and Experience

Researching a supplier’s reputation and experience in the industry can provide insight into their reliability. Look for customer reviews, testimonials, and case studies to gauge the supplier’s track record.

5. Pricing and Lead Times

While cost is an important consideration, it should not be the only factor. Evaluate suppliers not only based on pricing but also on their ability to meet lead times and supply demands promptly to avoid disruptions in your operations.

Conclusion

As industries continue to evolve and expand, so does the demand for quality welding materials. Suppliers of flux core welding wire in China play a crucial role in providing resources that meet these demands. By focusing on quality, product range, technical expertise, and reliability, welders can ensure they are well-equipped to handle projects with the best materials available. Exploring reputable suppliers in China is a step towards achieving excellence in welding projects, ultimately leading to high-quality results and enhanced productivity.

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025

-

Arc Welding Electrodes AWS E7024 – High Deposition, Smooth FinishNewsJul.30,2025

-

E7016 Welding Rods for Smooth, Low Hydrogen Welding PerformanceNewsJul.29,2025