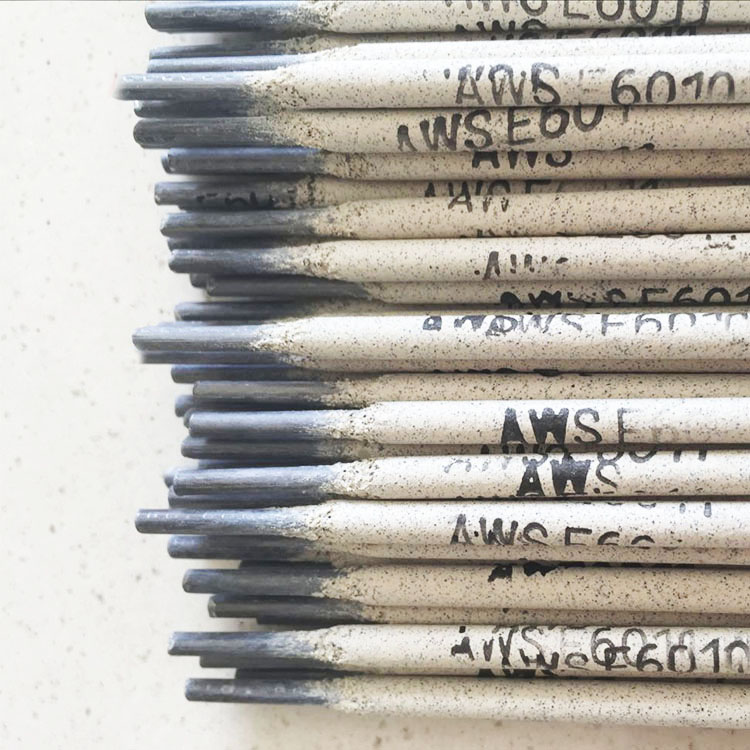

china stick welding rods

Understanding China Stick Welding Rods A Comprehensive Overview

Stick welding, also known as Shielded Metal Arc Welding (SMAW), is one of the most versatile and widely used welding processes across various industries. Central to the stick welding process are the welding rods, which play a pivotal role in determining the quality of the weld. China, being a global manufacturing hub, has positioned itself as a significant player in the production and export of stick welding rods. This article delves into the characteristics, benefits, and applications of China-made stick welding rods.

Key Features of Welding Rods

Welding rods used in stick welding consist of a core metal surrounded by a flux coating. The flux is essential as it facilitates the welding process by protecting the molten metal from atmospheric contamination, stabilizing the arc, and assisting in the formation of a slag that helps to clean and finish the weld. Chinese manufacturers produce a variety of welding rods suitable for different materials and welding conditions, including carbon steel, stainless steel, and cast iron rods.

Quality Standards and Certifications

One of the crucial considerations when selecting welding rods is the quality and compliance with international standards. Many Chinese manufacturers adhere to strict quality management systems and certifications, such as ISO 9001, to ensure that their products meet global standards. The use of advanced technology and modern manufacturing processes has allowed these companies to produce high-quality welding rods that are not only efficient but also durable under diverse welding conditions.

Economic Advantages

china stick welding rods

Cost-effectiveness is a significant advantage of Chinese stick welding rods. Due to lower production costs and the scale of manufacturing, these rods are often priced competitively without compromising on quality. This makes them an attractive choice for businesses looking to reduce operational costs while ensuring reliable welding performance. However, it is essential to choose reputable suppliers to ensure the rods meet the necessary standards and provide consistent quality.

Applications in Various Industries

China stick welding rods are used across a wide array of industries, including construction, automotive, shipbuilding, and manufacturing. Their versatility allows them to be employed in various applications—from heavy structural fabrication to intricate repair work. Different types of rods are designed for specific applications; for instance, stainless steel rods are ideal for construction environments requiring high corrosion resistance, while low-hydrogen rods are preferred for critical applications where weld integrity is paramount.

The Role of Innovation

Innovation in the production of stick welding rods is continually evolving in China. Manufacturers are investing in research and development to create new formulations and improve rod performance. This includes producing rods with enhanced arc stability, lower spatter levels, and improved weld toughness. Furthermore, the adoption of advanced technology, such as automation in manufacturing processes, contributes to the consistency and reliability of the products.

Conclusion

China's role in the global stick welding rod market is substantial, driven by its commitment to quality, innovation, and cost-effectiveness. For industries reliant on reliable welding solutions, choosing the right welding rods is crucial to achieving optimal results. By understanding the characteristics, applications, and benefits of Chinese stick welding rods, businesses can make informed decisions that enhance their welding operations. As industries continue to evolve, the demand for high-quality welding rods will persist, positioning China as a pivotal supplier in this essential sector.

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025

-

Arc Welding Electrodes AWS E7024 – High Deposition, Smooth FinishNewsJul.30,2025

-

E7016 Welding Rods for Smooth, Low Hydrogen Welding PerformanceNewsJul.29,2025

-

E7016 Welding Rods for High Strength & Low Hydrogen WeldingNewsJul.29,2025