china welding rod 3/32 factories

Overview of 3/32 Welding Rod Factories in China

The global welding industry has seen significant advancements in both technology and manufacturing processes, with China emerging as a leading supplier of welding consumables. Among these essential products are the 3/32-inch welding rods, which are widely used in various applications due to their versatility and performance. This article explores the landscape of factories producing 3/32-inch welding rods in China, highlighting their significance, production processes, and quality standards.

Importance of 3/32 Welding Rods

Welding rods, specifically 3/32-inch rods, are integral to many welding applications, including maintenance and repair work, automotive manufacturing, and metal fabrication. Their diameter allows for precision work in both thin and thick materials, making them favorable for welders looking for ease of use and reliability. The demand for quality welding rods has surged as industries continue to pursue high standards in fabrication and welding processes.

Manufacturing Facilities

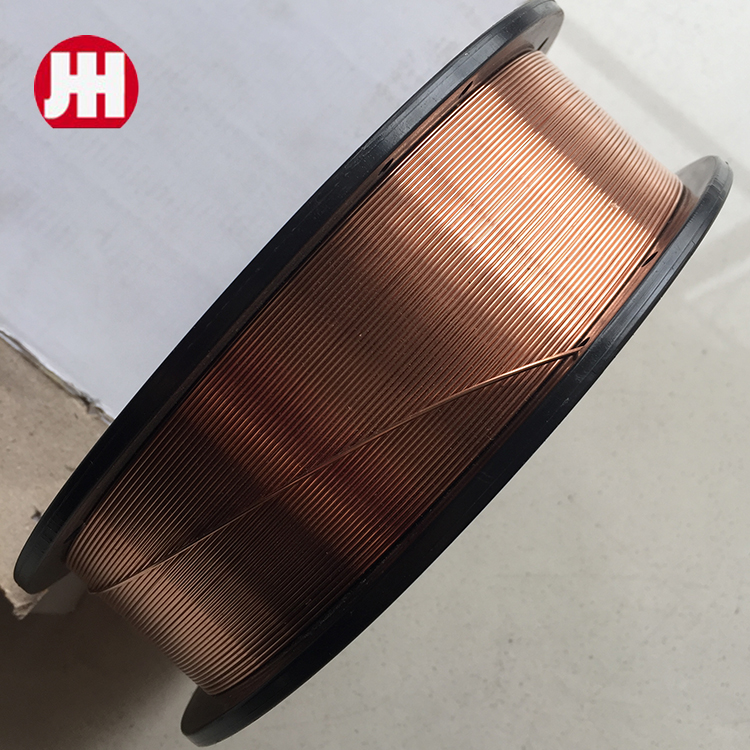

China hosts a multitude of factories specializing in the production of welding rods. These facilities are equipped with advanced machinery and technologies that streamline the manufacturing process, ensuring efficiency and consistency. The primary types of welding rods produced include mild steel, stainless steel, and alloy welding rods.

1. Production Process The manufacturing of 3/32-inch welding rods typically involves several key steps - Raw Material Sourcing Factories source high-quality materials, such as steel or alloy compositions, which are critical for the performance of the welding rod. - Melting and Casting The raw materials are melted and cast into specific shapes. This initial step is crucial as it determines the chemical composition and mechanical properties of the rods. - Rolling and Shaping The molten metal is then passed through rolling mills to achieve the desired diameter and shape. Precision is essential to ensure uniformity across the products. - Coating and Finishing For various welding rods, a flux coating is applied. This coating protects the weld area, facilitates arc stability, and helps produce a smooth weld bead. The rods are then cut to the required lengths and packaged for distribution.

2. Quality Control Chinese factories that produce 3/32 welding rods adhere to strict quality control measures. High-grade raw materials are tested for their mechanical properties before production begins. Additionally, each batch of welding rods undergoes rigorous testing for strength, flexibility, and weld quality to ensure they meet international standards, such as ISO 9001 and AWS specifications.

china welding rod 3/32 factories

Global Market Presence

Chinese manufacturers of 3/32 welding rods have gained a significant presence in the global market, exporting a substantial volume of products to various countries. Factors contributing to their success include competitive pricing, high production capacity, and the ability to meet diverse customer requirements. Many Chinese factories also offer customization options, allowing clients to specify unique formulations or branding on the products.

Challenges and Future Prospects

Despite their success, Chinese welding rod manufacturers face challenges such as fluctuating raw material prices and increasing environmental regulations. Factories must adapt by investing in sustainable practices and exploring alternative materials that minimize environmental impact.

Moreover, as global competition intensifies, Chinese manufacturers are focusing on innovation and research to improve product quality and develop new welding technologies. The emphasis on automation and smart manufacturing processes will likely play a significant role in shaping the future of the welding rod industry in China.

Conclusion

The production of 3/32 welding rods in China represents a critical component of the global welding supply chain. With advancements in technology and a strong commitment to quality, Chinese factories continue to meet the growing demands of the industry. As they navigate challenges and embrace innovation, the future looks promising for the welding rod manufacturing sector in China, ensuring that these essential tools remain available to welders around the world.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025