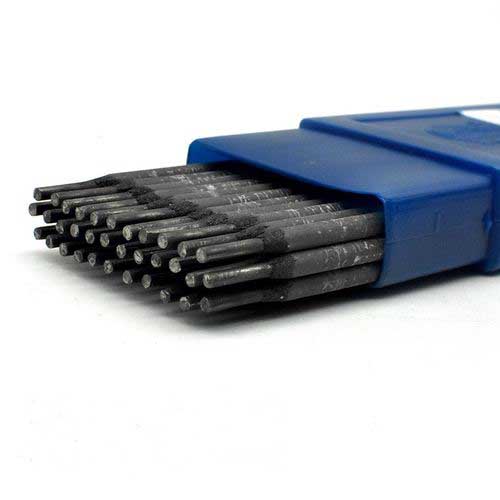

China welding rod 6013 welding electrodes aws e6013

Electrode welding, a cornerstone of modern fabrication, requires meticulous attention to quality, technique, and safety. For professionals in the industry, selecting the right electrodes and mastering the art of welding is paramount to ensuring durability and precision in every project. From novice welders to seasoned experts, the quest for excellence in welding is a journey defined by continuous learning and practical experience.

Central to the process is the selection of appropriate electrodes, each specifically designed to suit various types of metals and welding techniques. The electrodes act as a conduit for electric current, facilitating the fusion of materials under intense heat. Whether working with arc welding or alternative methods, understanding the nuances of electrode compositions—such as mild steel, stainless steel, or bronze—can dramatically influence the strength and quality of the weld.

Expertise in electrode welding encapsulates not only technical proficiency but also an authoritative knowledge of industry standards. Standards set by American Welding Society (AWS) and International Organization for Standardization (ISO) govern the classification, storage, and handling of welding electrodes. Familiarity with such standards empowers professionals to make informed decisions, optimizing both safety and efficiency. By adhering to these guidelines, welders reinforce the structural integrity of their projects and uphold the trustworthiness of their work.

Reliability in electrode welding also hinges on the authenticity and quality of the equipment used. Investing in high-caliber welding machines and protective gear is non-negotiable for ensuring safety and achieving precision. Moreover, the maintenance of these tools through regular inspections and calibrations is crucial to preserving their functionality and extending their lifespan.

electrodes welding

The essence of trustworthiness in welding practices is reflected in the commitment to safety protocols. Wearing protective gear, such as helmets, gloves, and aprons, and maintaining a clean working environment are critical measures that safeguard not only the welder but also the workpiece. Prioritizing safety fosters an atmosphere of responsibility and professionalism, key traits that clients and peers recognize and value.

In the rapidly evolving landscape of welding technology, staying abreast of innovations is a testament to a professional’s dedication to their craft. Emerging techniques, like robotic welding and advanced automation, offer exciting opportunities to enhance productivity and precision. By embracing these advancements, welders can refine their skills, expand their expertise, and maintain a competitive edge in the market.

Ultimately, the art of electrode welding combines the tangible elements of skill and equipment with the intangible aspects of knowledge and reliability. The product of this delicate balance is not just a bond between metals, but a testament to the welder’s proficiency and ethical commitment. As professionals continue to explore the depths of this dynamic field, they contribute to a legacy that values quality, innovation, and unwavering trust.

-

Premium Carbon Rods for Welding | Stable Arc & Precise GougingNewsAug.27,2025

-

Carbon Steel Welding Wire: Superior Strength & PrecisionNewsAug.26,2025

-

AWS E6013 Welding Electrodes: All-Position & Smooth Arc RodsNewsAug.25,2025

-

E312 Electrode: High Strength Welding Rod for Dissimilar MetalsNewsAug.24,2025

-

J506 Welding Rod: High-Strength, Crack-Resistant ElectrodeNewsAug.23,2025

-

E71T-1 Shielding Gas for Superior Welding Quality & EfficiencyNewsAug.22,2025