mig welding wire 5kg supplier

The Importance of Choosing the Right MIG Welding Wire Supplier

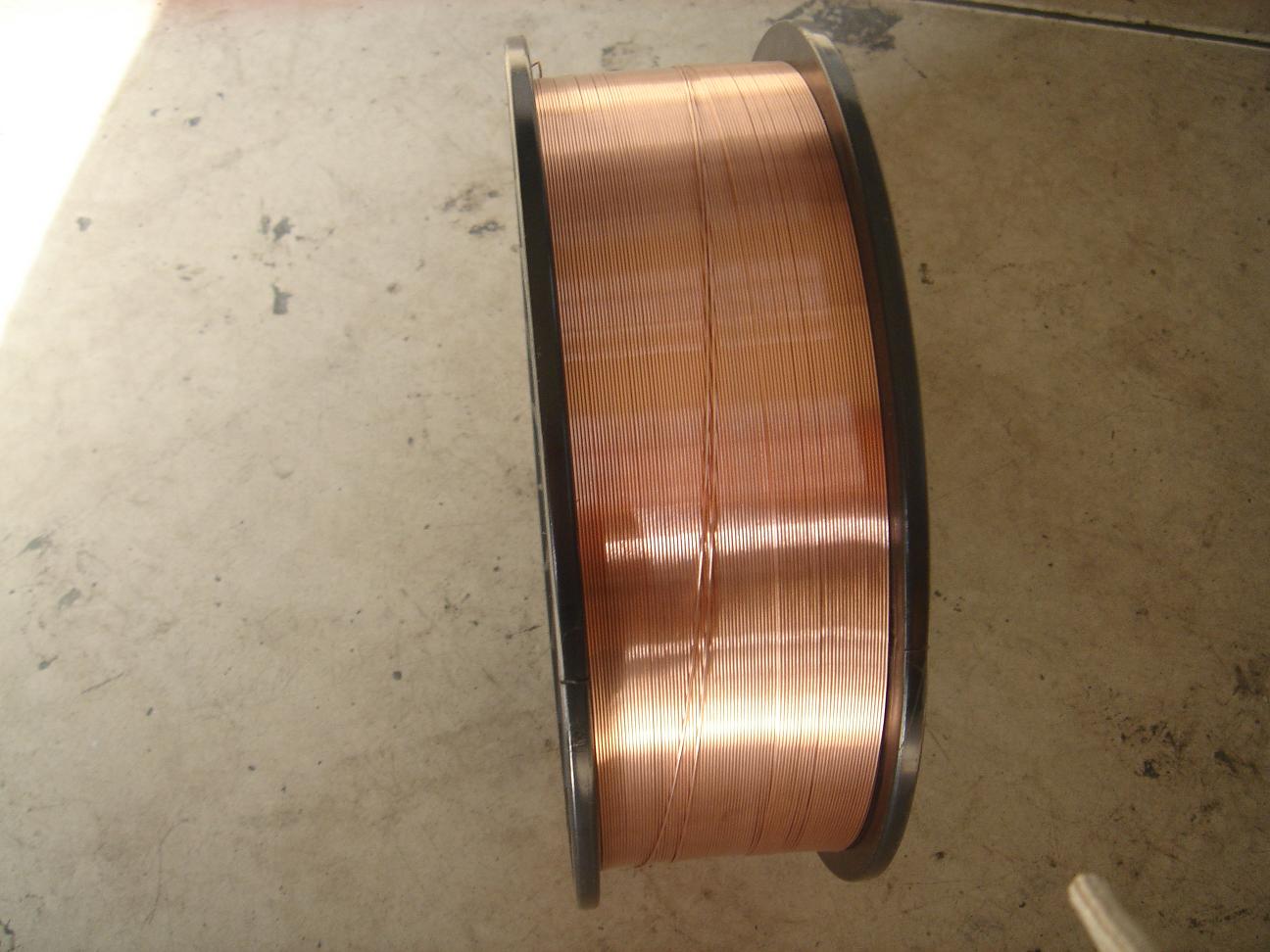

When it comes to metal fabrication and welding, selecting the right materials is essential for achieving optimal results. One crucial component in the MIG (Metal Inert Gas) welding process is the welding wire. For any welding project, reliability, quality, and efficiency hinge on the proper selection of MIG welding wire, often available in 5kg spools for ease of use and handling. Therefore, finding a trustworthy MIG welding wire supplier becomes critical for fabricators and welders aiming for excellence in their work.

Understanding MIG Welding Wire

Before diving into the importance of selecting a reliable supplier, it's essential to understand what MIG welding wire is and how it influences the welding process. MIG welding is a commonly used method that feeds a continuous solid wire electrode through a welding gun into the weld pool. The wire melts and fuses two or more pieces of metal together. The choice of welding wire varies based on factors like the type of metal being welded, the specific welding position, and the desired properties of the weld.

MIG welding wire is typically classified by its diameter, material composition, and coating. Common materials include ER70S-6 for carbon steel and ER308L for stainless steel. Each type of wire offers specific benefits and works best with particular welding machines and settings.

Why Selecting the Right Supplier Matters

Quality Assurance A reputable MIG welding wire supplier ensures that their products meet industry standards and regulations. Quality wire translates into better welds, reduced splatter, and less post-weld cleanup. Subpar wire may lead to weak joints, which can compromise the integrity of the final product and potentially lead to safety hazards.

Variety of Options Different projects require different types of welding wire, and a good supplier will offer a broad range of options. A reliable supplier will understand the unique needs of their customers and provide specialized solutions. This includes offering various wire diameters, materials, and spool sizes beyond just the standard 5kg size, allowing welders to choose the best product for their applications.

Availability and Delivery Project timelines can be tight, and delays in material supply can lead to considerable setbacks. A dependable supplier offers prompt delivery and maintains a well-stocked inventory. This reliability ensures that customers can acquire their required wire without unnecessary delays.

Technical Support A knowledgeable supplier serves not only as a vendor but also as a resource. They should be equipped to provide technical assistance, guiding customers in selecting the right welding wire for their particular project. This can include help with machine settings, welding techniques, and troubleshooting issues.

mig welding wire 5kg supplier

Finding the Right MIG Welding Wire Supplier

When searching for the ideal MIG welding wire supplier, there are several criteria to consider

1. Reputation and Reviews Investigate the supplier's reputation within the industry. Look for customer testimonials, reviews, and testimonials. A satisfied customer base speaks volumes about the reliability and quality of products.

2. Product Certifications Confirm that the welding wire meets applicable certifications and standards. This can include ISO certifications, ensuring that the supplier adheres to quality management systems.

3. Experience An established supplier with years of experience in the industry is often better equipped to meet diverse customer needs and provide high-quality products.

4. Customer Service Assess the supplier's customer service capabilities. Are they easy to contact? Do they answer inquiries promptly? Excellent customer service goes hand-in-hand with reliability.

5. Pricing While quality should be a priority, it’s important to find a supplier that offers competitive pricing. Compare costs among different suppliers to ensure you get value for your investment.

Conclusion

In conclusion, selecting the right MIG welding wire supplier is pivotal for anyone involved in metal fabrication and welding. Quality, variety, availability, and technical support are all essential factors that can significantly impact the outcomes of welding projects. A reliable supplier not only provides high-quality products but also contributes to the overall success of the welding process. By taking the time to research and choose the right partner for your welding wire needs, you can ensure that your projects are completed effectively, efficiently, and safely.

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025

-

Best Stainless Steel Flux Core Wire 030 for Welding – High Strength & Clean WeldsNewsJul.06,2025

-

High-Performance Hard Facing Welding Rod – Durable & Wear-Resistant Electrodes for Industrial UseNewsJul.05,2025