Stainless Steel Welding Rod Manufacturers and Their Production Techniques

Understanding Stainless Steel Welding Rod Factories

Stainless steel welding rods play a crucial role in the fabrication and repair processes across various industries. The demand for high-quality welding materials has led to the establishment and growth of stainless steel welding rod factories around the world. In this article, we will explore what these factories do, the manufacturing process behind stainless steel welding rods, and the implications for industries that rely on them.

The Importance of Stainless Steel Welding Rods

Stainless steel is known for its corrosion resistance, strength, and durability. As a result, it is the material of choice in many applications, including construction, automotive, aerospace, and manufacturing. Welding rods made from stainless steel are essential for joining stainless steel components since they ensure the integrity and strength of the weld joint. These rods can be used in both manual and automated welding processes, making them versatile and widely applicable.

Overview of Stainless Steel Welding Rod Factories

Stainless steel welding rod factories are specialized manufacturing facilities that produce welding rods made from various stainless steel alloys. These factories are equipped with advanced machinery and technology to ensure precision and quality in their products. The manufacturing process typically involves several stages, including sourcing raw materials, alloying, drawing, and packaging.

1. Sourcing Raw Materials The first step in producing stainless steel welding rods is sourcing high-quality raw materials. The primary constituents of stainless steel include iron, chromium, nickel, and other alloying elements. Factories usually establish relationships with reliable suppliers to obtain these materials, ensuring consistency in the quality of the rods.

2. Alloying After obtaining the raw materials, the next step involves melting and alloying them in large furnaces. The specific composition of each batch is carefully measured to meet industry standards or specific customer requirements. The molten metal is then poured into molds to create ingots, which will eventually be processed into welding rods.

stainless welding rod factories

3. Drawing The ingots are then subjected to a process called drawing, where they are heated and pulled through a series of dies to achieve the desired diameter and length. This process requires precision, as inconsistencies can lead to defects in the rods. The rods are continuously monitored for quality during this stage.

4. Finishing After drawing, the rods undergo additional finishing processes to improve their surface quality. These processes may include pickling and passivation, which remove any oxides or contaminants, enhancing corrosion resistance. Once finished, the rods are cut to specific lengths and packaged for distribution.

Quality Control and Standards

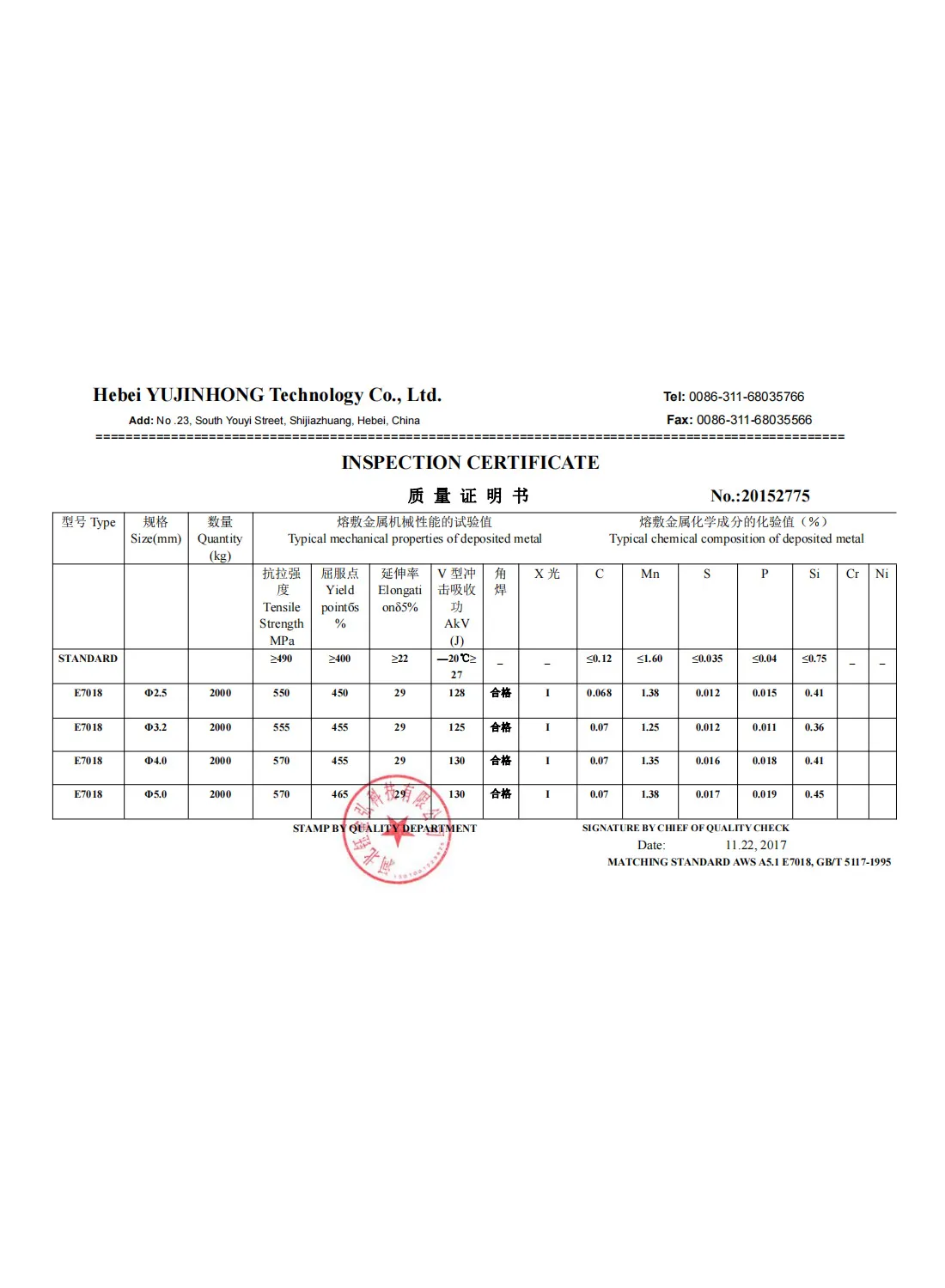

Quality control is a vital aspect of stainless steel welding rod production. Factories implement rigorous testing procedures to ensure that the rods meet both international standards and customer specifications. This may include tensile testing, chemical composition analysis, and visual inspections. Compliance with standards such as ISO and AWS is essential for maintaining credibility and ensuring client satisfaction.

The Market for Stainless Steel Welding Rods

The global market for stainless steel welding rods has been steadily expanding, driven by growth in construction, manufacturing, and automotive sectors. The increasing demand for high-performance materials that can withstand harsh environments has further propelled this growth. Manufacturers are continually innovating, developing new alloys and rod types to cater to specific applications, such as underwater welding and high-temperature environments.

Conclusion

In conclusion, stainless steel welding rod factories are vital components of the manufacturing landscape. They ensure the production of high-quality welding materials that are essential for countless applications across various industries. With a focus on quality control, technological advancements, and customer satisfaction, these factories are well-positioned to meet the evolving demands of the global market. As industries continue to innovate and require more specialized welding solutions, the importance of stainless steel welding rods and their manufacturers cannot be overstated. As we look toward the future, these factories will play a critical role in supporting the infrastructure and technologies that shape our modern world.

-

Premium AC Stainless Steel Welding Rods - Durable & Corrosion-ResistantNewsAug.05,2025

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025