welding rod 3.2mm factory

Exploring the World of 3.2mm Welding Rods A Factory Perspective

Welding is an essential process in various industries, from construction to manufacturing. One of the key components in this process is the welding rod, which is used to join metal pieces together. Among the various sizes available, the 3.2mm welding rod has gained popularity due to its versatility and effectiveness. In this article, we will explore the significance of 3.2mm welding rods from a factory perspective, focusing on their production, applications, and benefits.

Understanding Welding Rods

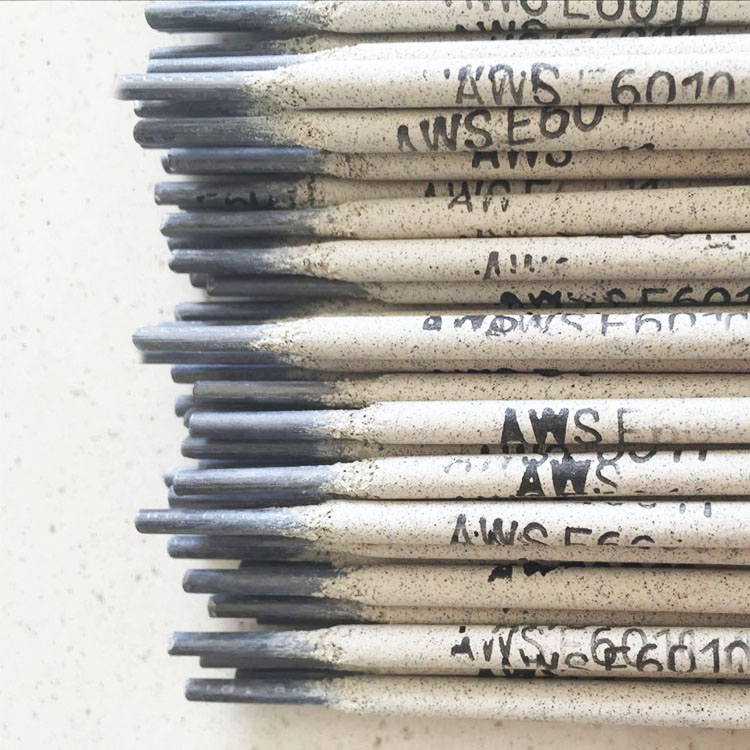

Welding rods, also known as electrodes, are metal wires coated with a material that helps to create a strong bond between two metal surfaces. The 3.2mm diameter is particularly favored for its compatibility with various welding techniques, including MIG, TIG, and stick welding. This size strikes a balance between ease of handling and sufficient deposition of filler material, making it ideal for both amateur and professional welders.

Production Process

The manufacturing of 3.2mm welding rods involves several critical steps. First, raw materials such as steel and coating substances are sourced. The steel is then drawn down to the desired diameter, ensuring a uniform size and quality. After the rods are formed, they undergo a coating application process, where a protective flux is added to enhance the welding properties. This coating plays a crucial role in stabilizing the arc and protecting the weld pool from contamination.

Quality control is paramount during production. Factories deploy rigorous testing methods to ensure that each welding rod meets industry standards. This includes checking for tensile strength, flexibility, and corrosion resistance. By adhering to these standards, welding rod manufacturers ensure that their products are reliable and effective for a range of applications.

Applications of 3

.2mm Welding Rodswelding rod 3.2mm factory

3.2mm welding rods are immensely popular across several sectors. In the construction industry, they are used to fabricate and repair structural steel components. Their versatility allows for use in various welding techniques, making them suitable for both thin and thick materials. Automotive manufacturing also relies on 3.2mm rods for assembling vehicle frames and components, where precision and strength are paramount.

Additionally, these rods find applications in maintenance and repair work, where welders often need a dependable filler material to restore the integrity of worn or damaged metal parts. Tool and equipment fabrication also benefits from the attributes of 3.2mm rods, leading to durable and long-lasting products.

Advantages of Using 3.2mm Welding Rods

One of the significant advantages of using 3.2mm welding rods is their ease of use. Welders, whether novices or experienced, find this diameter manageable, contributing to more controlled and precise welds. Additionally, the rods offer excellent arc stability, which is critical for achieving high-quality welds. They also allow for a smooth feed and consistent weld deposition, minimizing the risk of defects.

Moreover, the coating on 3.2mm welding rods enhances their performance by improving the fluidity of the molten metal, reducing spatter, and facilitating better penetration into the base materials.

Conclusion

In conclusion, 3.2mm welding rods play an indispensable role in the welding industry. Their manufacturing process, application versatility, and numerous advantages make them a go-to choice for welders across various sectors. As technology advances, we can expect further improvements in the quality and performance of these essential components, ultimately contributing to stronger and more reliable metal constructions worldwide.

-

Affordable Welding Rod 309 Prices SS 309 & Copper Electrode DealsNewsMay.23,2025

-

Flux Core MIG Welding Stainless Steel Wire High-Corrosion Resistance & DurableNewsMay.23,2025

-

Flux Core Welder for Aluminum Minimig 100E & Compact SolutionsNewsMay.23,2025

-

Best 6013 Welding Electrode Price Durable Rods & Bulk DiscountsNewsMay.22,2025

-

E71T-1 & E71T-11 Welding Wire Specs High-Strength Flux-Cored WireNewsMay.22,2025

-

Galvanized Steel Welding Rods & Flux Core Wires Anti-Rust SolutionsNewsMay.22,2025