Welding Wire 030 Specifications and Applications for Optimal Performance

The Importance of Welding Wire A Focus on 0.030 Inch Diameter

Welding is an indispensable process in various industries, enabling the joining of metals and other materials to create robust structures and components. Among the myriad of welding materials available, welding wire plays a crucial role. In this article, we will delve into the significance of welding wire, particularly focusing on the 0.030-inch diameter type, exploring its applications, advantages, and considerations for proper use.

Understanding Welding Wire

Welding wire serves as a filler material in various welding processes, most notably in gas metal arc welding (GMAW), sometimes referred to as MIG (Metal Inert Gas) welding. The wire is fed through the welding gun, where it melts and combines with the base material to form a weld. Different diameters and compositions of welding wire cater to specific applications and materials.

The 0.030-Inch Diameter Welding Wire

The 0.030-inch welding wire is among the most popular sizes used in MIG welding due to its versatile applications. Its diameter provides an ideal balance between control and penetration, making it suitable for a wide range of materials, including mild steel, stainless steel, and aluminum.

1. Applications in Various Industries - Automotive The automotive industry relies heavily on welding for assembling components such as frames, exhaust systems, and chassis parts. The 0.030-inch wire is perfect for thin to medium gauge materials, providing strong and smooth welds essential for vehicle durability and safety. - Construction In construction, this welding wire is used for fabricating structural components, ensuring that buildings and other infrastructures meet strict quality standards. - Manufacturing Various manufactured products, from household appliances to industrial equipment, benefit from the precision and efficiency offered by the 0.030-inch welding wire.

2. Versatility and Efficiency - One of the significant advantages of using a 0.030-inch welding wire is its versatility. It can be used in different welding processes and with a variety of shielding gases, adapting easily to various project requirements. This flexibility enhances productivity, allowing welders to switch between tasks without needing to change equipment drastically. - Additionally, the size of the wire aids in achieving a clean weld. The smaller diameter allows for precise control over the heat input, which minimizes distortion and ensures quality results, especially crucial in industries that prioritize safety and structural integrity.

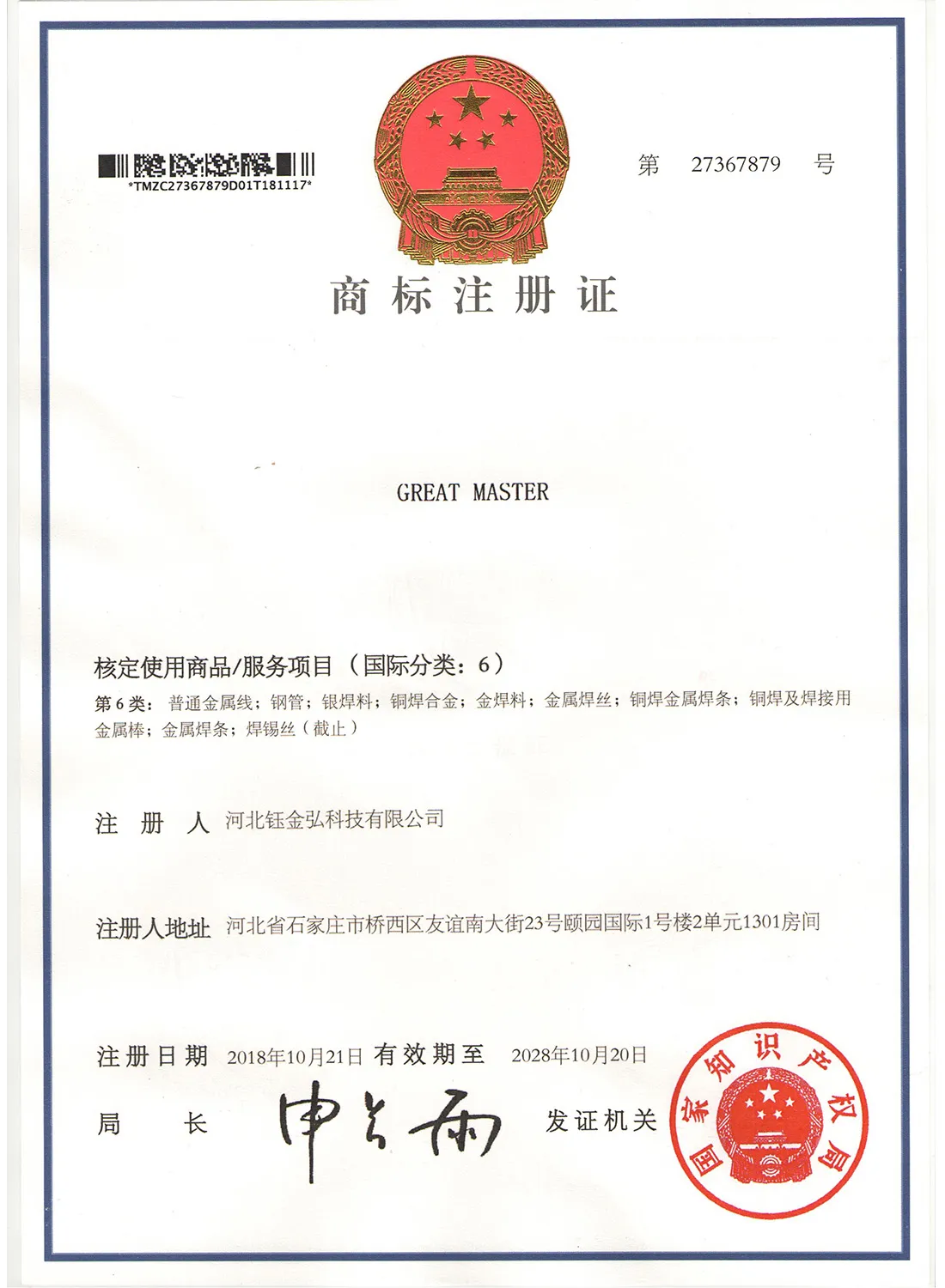

welding wire 030

Advantages of Using 0

.030-Inch Welding WireThe choice of a 0.030-inch diameter welding wire extends beyond convenience—multiple benefits underscore its popularity

- Controlled Penetration The diameter allows for effective penetration into the joint while retaining a manageable heat input, crucial in preventing burn-through in thinner materials. - Reduced Spatter A well-controlled welding wire diameter results in less spatter, making post-weld cleanup easier and contributing to the aesthetic appearance of the weld. - Compatibility The 0.030-inch wire is compatible with various welding machines and power settings, making it an excellent choice for both novice and experienced welders.

Considerations for Proper Use

While the 0.030-inch welding wire offers several advantages, it is essential to consider a few factors to ensure optimal performance

- Wire Type Various types of welding wires are available, including ER70S-6 for mild steel and ER308L for stainless steel. Choosing the right type ensures compatibility with the base materials being welded. - Shielding Gas The effectiveness of the wire can also depend on the selection of shielding gas, such as argon or CO2. The correct gas minimizes oxidation and improves weld quality. - Technique Lastly, the welder's technique significantly impacts the outcome. Practicing proper welding techniques ensures that the benefits of the 0.030-inch wire are fully realized.

Conclusion

In essence, the 0.030-inch welding wire is a fundamental component in the welding landscape, bridging the gap between various materials and applications. Its versatility, efficiency, and ability to produce high-quality welds make it a favored choice across numerous industries. Understanding its proper use and the conditions under which it performs best can further enhance the quality and integrity of welded structures. As is evident, selecting the right wire is essential for achieving successful and reliable results in welding projects.

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025

-

Premium AC Stainless Steel Welding Rods - Durable & Corrosion-ResistantNewsAug.05,2025

-

E7018 Welding Rods: Premium Low Hydrogen ElectrodesNewsAug.04,2025

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025