Wholesale Manufacturing of 7018 Welding Electrodes for Industrial Applications

Exploring Wholesale 7018 Welding Electrodes A Guide for Manufacturers

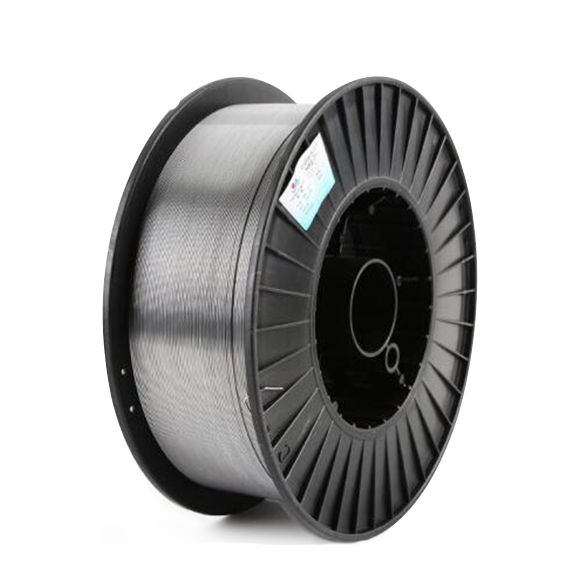

In the world of welding, the choice of electrodes is crucial for achieving high-quality welds. This is especially true for manufacturers involved in heavy-duty applications, where the strength and durability of welds are paramount. One of the most popular options is the 7018 welding electrode, which is known for its excellent performance in a variety of welding tasks. This article explores the features, benefits, and considerations for manufacturers when sourcing wholesale 7018 electrodes.

Understanding 7018 Welding Electrodes

The 7018 welding electrode, categorized as an electrode for shielded metal arc welding (SMAW), is renowned for its low-hydrogen composition. The designation 7018 indicates that the electrode can be used to weld steels of a yield strength of 70,000 psi, and it is characterized by its good notch toughness. These properties make 7018 electrodes particularly effective for welding structural steel, pressure vessels, and pipes.

One of the defining features of 7018 electrodes is their ability to produce clean and strong welds. The low-hydrogen content minimizes the risk of hydrogen-induced cracking, an essential factor when welding high-strength steels. Additionally, 7018 electrodes allow for smooth arc stability and excellent bead appearance, making them a preferred choice for professionals in the welding industry.

Advantages of Wholesale Purchasing

For manufacturers looking to procure 7018 electrodes, buying in bulk through wholesale suppliers presents numerous advantages.

1. Cost Efficiency Purchasing electrodes wholesale typically leads to significant cost savings. Bulk orders mean lower prices per unit, which can help manufacturers manage their budgets more effectively, particularly in large-scale projects where welding needs are high.

2. Consistent Quality Established wholesale suppliers often source their electrodes from reputable manufacturers, ensuring consistent quality across batches. This reliability is crucial in maintaining the integrity of welds, especially in critical applications.

3. Availability of Varieties Wholesale suppliers often provide a wider range of welding electrodes and related products, enabling manufacturers to easily find specific types of 7018 electrodes tailored to their unique requirements. This variety can include different diameters and lengths, which are vital depending on the project specifications.

wholesale 7018 electrodo para soldar manufacturers

4. Convenience in Procurement Maintaining stock of welding consumables is essential for seamless operations. Wholesale purchasing simplifies procurement processes, reduces the frequency of orders, and ensures that manufacturers have adequate supplies on hand to meet production demands.

Factors to Consider When Sourcing 7018 Electrodes

When sourcing 7018 welding electrodes wholesale, manufacturers should consider several factors to ensure they choose the right supplier and products

- Supplier Reputation Research suppliers for their reliability and customer feedback. A well-established supplier will often offer the best quality and service.

- Certifications and Standards Ensure that the electrodes meet relevant industry standards and certifications. This is crucial for compliance and ensuring the safety and performance of welding operations.

- Shipping and Delivery Analyze the logistics side of your procurement. Timely delivery is essential to avoid delays in production. Evaluate the shipping options provided by the supplier.

- Technical Support A supplier that offers technical assistance or guidance on best practices for using 7018 electrodes can be invaluable, especially for manufacturers new to this welding method.

Conclusion

In conclusion, the wholesaling of 7018 welding electrodes provides numerous benefits for manufacturers seeking to enhance their welding applications. From cost savings to consistency in quality, sourcing these electrodes in bulk not only streamlines operations but also contributes to the overall efficiency of manufacturing processes. By carefully selecting a reliable supplier and considering critical factors, manufacturers can ensure they obtain high-quality electrodes that meet their specific welding needs. Investing in the right materials is fundamental to producing durable and high-strength welds that stand the test of time.

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025

-

E309 Welding Electrode: Premium Stainless Steel Stick RodsNewsAug.09,2025

-

Premium Solid MIG Wire for Strong, Reliable WeldsNewsAug.08,2025

-

E6010 Cellulose Electrode: Deep Penetration Steel Welding RodNewsAug.07,2025

-

Premium E316L Welding Rod for 316L Stainless SteelNewsAug.06,2025