wholesale filler rod tig welding

Understanding Wholesale Filler Rods for TIG Welding

TIG (Tungsten Inert Gas) welding is a versatile and precise welding process widely used in various industries, including automotive, aerospace, and manufacturing. One of the key components that ensure the success of TIG welding is the filler rod. This article delves into wholesale filler rods for TIG welding, emphasizing their importance, types, and the benefits of purchasing in bulk.

The Importance of Filler Rods in TIG Welding

Filler rods are a vital consumable in the TIG welding process, used to fill the weld joint between two base materials. They help in creating a strong, durable bond that can withstand various stresses. The choice of filler rod is crucial as it should match the base materials being welded to ensure compatibility in terms of strength, corrosion resistance, and thermal expansion.

In TIG welding, the filler rod is introduced manually into the weld pool created by the heat generated from the tungsten electrode. This allows for precise control and a high-quality finish, making TIG welding suitable for applications requiring high aesthetic standards and robust performance.

Types of Filler Rods

Filler rods come in various materials and specifications, each designed for different applications

1. Aluminum Filler Rods Used for welding aluminum and its alloys, these rods are typically made of 4047 or 5356 alloys. They offer good fluidity and excellent corrosion resistance, which is essential for automotive and marine applications.

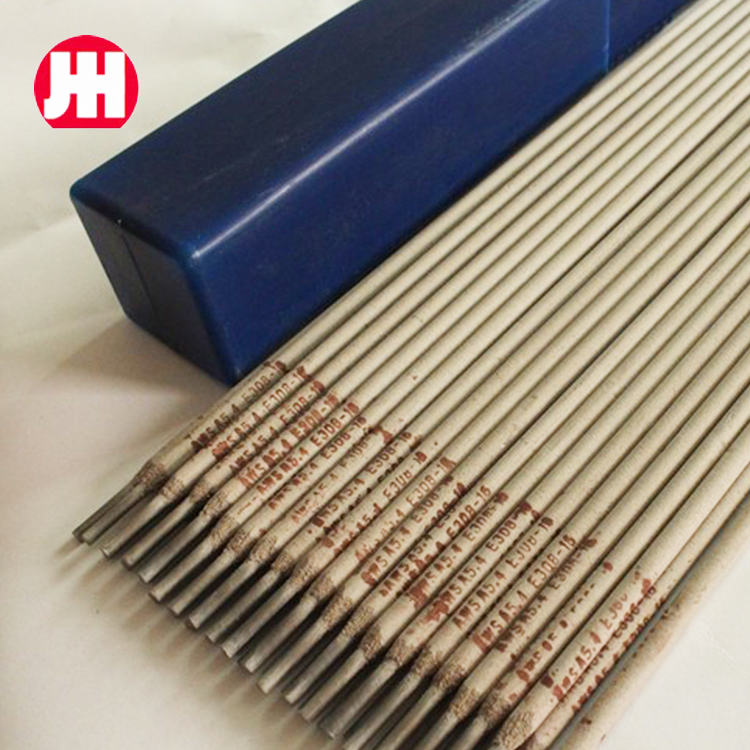

2. Stainless Steel Filler Rods These rods are essential for welding stainless steel components. Common types include ER308L, ER309L, and ER316L, each suited for different grades of stainless steel and specific applications, such as food processing equipment and chemical containers.

3. Carbon Steel Filler Rods Suitable for welding carbon steel structures, these rods provide excellent strength and are often used in construction and structural applications.

4. Nickel Alloys and Special Alloys These rods are used for welding high-performance materials, often in specialized industries such as aerospace and oil and gas.

wholesale filler rod tig welding

Each type of filler rod has its unique properties, making it essential for welders to select the appropriate rod based on the materials they are joining

.Purchasing Wholesale Filler Rods

Buying filler rods wholesale offers numerous advantages for businesses and individual welders alike. Here are some of the key benefits

1. Cost Savings Purchasing in bulk often leads to significant cost reductions. Wholesale suppliers typically offer lower prices per unit as compared to retail prices. This is especially beneficial for companies that require large quantities for ongoing projects.

2. Consistent Supply A wholesale order ensures a steady supply of filler rods, helping to avoid delays in projects. Consistency in supply is critical in production environments where equipment downtime can lead to financial losses.

3. Quality Assurance Wholesalers often have established relationships with manufacturers, ensuring that the products they sell meet industry standards. This reliability in product quality is essential for maintaining the integrity of welds.

4. Customization Options Some wholesale suppliers offer customization in terms of rod size, packaging, and materials, allowing businesses to get exactly what they need based on their specific welding requirements.

5. Access to a Range of Products Wholesale suppliers often provide a broader range of filler rods, enabling welders to select the best rod for their application without needing to shop from multiple sources.

Conclusion

Filler rods are indispensable in TIG welding, influencing the quality and strength of the final weld. Understanding the types of filler rods available and the advantages of purchasing them wholesale can significantly benefit both individual welders and businesses. By investing in quality filler rods and ensuring a steady supply, welders can enhance their productivity and efficiency, ultimately leading to better project outcomes and customer satisfaction. With the right filler rod and resources, the possibilities in TIG welding are virtually limitless.

-

High-Strength Cast Iron Welding Electrode AWS ENi-ClNewsAug.03,2025

-

E6011 Welding Rod | All-Position AC/DC ElectrodesNewsAug.02,2025

-

J422 Welding Rod: Durable Electrodes for Strong WeldsNewsAug.01,2025

-

AWS E7024 Arc Welding Electrodes: High-Efficiency & Easy UseNewsJul.31,2025

-

AWS E7018 Welding Rod: Low Hydrogen ElectrodesNewsJul.31,2025

-

Arc Welding Electrodes AWS E7024 – High Deposition, Smooth FinishNewsJul.30,2025