wholesale stainless steel stick welding

The Future of Wholesale Stainless Steel Stick Welding Trends and Advantages

In today's rapidly advancing manufacturing landscape, stainless steel remains one of the most sought-after materials due to its durability, corrosion resistance, and aesthetic appeal. Among the various welding methods used to join stainless steel components, stick welding, also known as Shielded Metal Arc Welding (SMAW), has carved out a niche as a reliable and effective technique, especially in wholesale applications. This article explores the advantages of wholesale stainless steel stick welding, its applications, and emerging trends shaping the industry.

Understanding Stick Welding

Stick welding involves using a welding rod coated with flux, which melts and creates a protective gas shield around the weld pool. This process is particularly advantageous for stainless steel because it allows for high penetration and is effective in outdoor environments where wind may disrupt other welding processes. The portability and simplicity of stick welding make it a preferred choice for many manufacturers, contractors, and artisans working with stainless steel.

Advantages of Wholesale Stainless Steel Stick Welding

1. Cost-Effectiveness One of the most significant advantages of wholesale stainless steel stick welding is its cost-effectiveness. It is generally less expensive than other welding processes like TIG or MIG welding, especially when high-quality stainless steel is required in bulk. Wholesale pricing and large quantities can further reduce costs, making it an attractive choice for businesses looking to maintain budgets without compromising quality.

2. Versatility Stick welding is remarkably versatile and can be used on various types and thicknesses of stainless steel. Whether for fabricating frames, creating structures, or repairing machinery, stick welding can accommodate a wide range of applications. This adaptability makes stick welding an invaluable technique in many industries, including construction, manufacturing, and automotive sectors.

3. Durability and Strength The welds produced by stick welding are known for their strength and durability. When performed correctly, stick welding can create robust joints that withstand significant stress and environmental factors. This strength is particularly important in wholesale applications where the final product must endure rigorous use and exposure.

4. Minimal Preparation Required Unlike other welding methods that may necessitate extensive surface preparation, stick welding requires minimal cleaning and setup. This makes it an efficient choice for bulk projects, allowing for quicker turnaround times without sacrificing quality.

wholesale stainless steel stick welding

5. Ease of Use Stick welding is relatively easy to learn and master compared to other welding techniques. Many operators find that with proper training, they can become proficient in stick welding in a short amount of time. This factor significantly reduces labor costs, further enhancing the cost benefits of wholesale stainless steel stick welding.

Emerging Trends in the Industry

As the demand for stainless steel continues to grow, several trends are emerging within the wholesale stick welding sector

1. Automation and Robotics With the rise of Industry 4.0, more manufacturers are incorporating automation and robotics into their welding processes. Automated stick welding systems can enhance efficiency, improve weld quality, and reduce labor costs. As technology continues to advance, we can expect an increase in the adoption of automated solutions within wholesale environments.

2. Green Welding Practices There is a growing emphasis on sustainability in the manufacturing sector. Companies are seeking eco-friendly practices, including the use of less toxic materials and energy-efficient welding processes. The integration of environmentally friendly methods in stick welding can attract businesses looking to enhance their sustainability credentials.

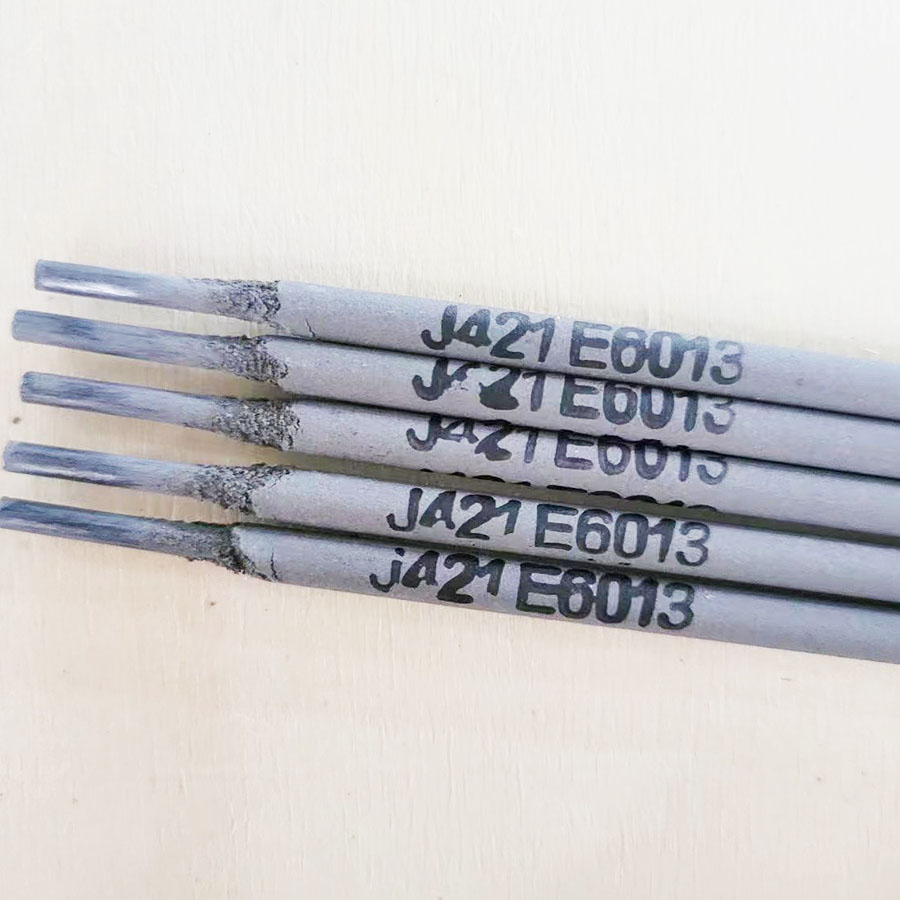

3. Advanced Welding Rods and Equipment Innovations in welding materials, such as high-performance electrodes designed for stainless steel, are improving the efficacy and reliability of stick welding. Additionally, advancements in welding equipment are making it more efficient to perform high-quality welds in wholesale applications.

4. Training and Skill Development As welding technology evolves, so does the need for skilled operators. Many companies are investing in training programs to ensure that their workforce is proficient in the latest techniques and technologies, enabling them to meet the market's growing demands.

Conclusion

Wholesale stainless steel stick welding presents numerous advantages, from cost-effectiveness and versatility to durability and ease of use. As the industry progresses, emerging trends such as automation, sustainability, and advanced materials will further influence this sector. For businesses looking to harness the advantages of stainless steel through stick welding, understanding these trends and the inherent benefits of the process will be crucial for maintaining competitiveness in a dynamic marketplace.

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025