wholesale wire welding aws er 70s-6 manufacturer

Understanding Wholesale Wire Welding AWS ER 70S-6 Manufacturer Insights

In the realm of welding, the choice of materials and the quality of the products play a significant role in the overall success of welding operations. Among the various welding wires available, AWS ER 70S-6 has emerged as a preferred option for many professionals in the industry. This article explores the significance of wholesale wire welding, focusing specifically on the AWS ER 70S-6 standard, and provides valuable insights into the manufacturing process.

What is AWS ER 70S-6?

AWS ER 70S-6 is a widely used welding wire that conforms to the standards set by the American Welding Society (AWS). The ER stands for Electrode Rod, indicating that it can be used in both MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding processes. The 70 refers to the minimum tensile strength of the deposited weld metal, which is 70,000 psi. The S-6 designates specific chemical composition and mechanical properties that meet stringent welding requirements.

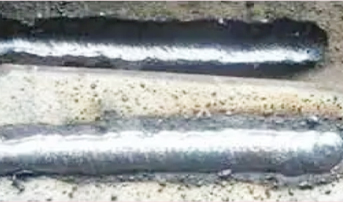

One of the key attributes of the AWS ER 70S-6 wire is its ability to produce high-quality welds across various materials, especially carbon steels and low-alloy steels. Its excellent arc stability and low spatter provide a clean and efficient welding environment, making it a preferred choice for numerous applications, including structural fabrication, automotive manufacturing, and general fabrication work.

The Importance of Wholesale Supply

For manufacturers and welding shops, sourcing high-quality welding wire at competitive prices is crucial. This is where the importance of wholesale suppliers becomes evident. Wholesale distributors provide welding wire in bulk quantities, enabling businesses to reduce costs significantly compared to retail purchases. Moreover, buying in bulk ensures that welding operations can proceed without interruptions caused by low inventory levels.

Wholesale suppliers of AWS ER 70S-6 wire play a vital role in ensuring that the welding industry has access to reliable materials. They often collaborate closely with manufacturers to ensure the quality and consistency of the welding wire. A trustworthy wholesale supplier will have a robust quality assurance process in place, ensuring that every batch of wire meets the required standards.

Selecting a Reliable Manufacturer

wholesale wire welding aws er 70s-6 manufacturer

When it comes to selecting a manufacturer of AWS ER 70S-6 welding wire, several factors should be considered

1. Quality Control A reputable manufacturer will have stringent quality control measures in place. Look for manufacturers that have certifications, such as ISO 9001, which ensures they adhere to international quality management standards.

2. Reputation and Experience A company with a long-standing reputation and experience in the welding industry will likely provide product reliability. Research customer reviews and case studies to gauge their performance in the market.

3. Product Range While AWS ER 70S-6 is a popular choice, manufacturers that offer a range of welding materials—including different wire types and sizes—can provide added flexibility to meet various project requirements.

4. Customer Service A responsive and knowledgeable customer service team can be invaluable, especially when questions or issues arise. A manufacturer that prioritizes customer satisfaction is more likely to foster long-term relationships with its clients.

5. Technical Support Technical expertise can make a significant difference in ensuring successful welding operations. Manufacturers that offer technical support can help customers select the right products for their specific applications and troubleshoot any potential issues.

Conclusion

In summary, AWS ER 70S-6 welding wire stands out as a versatile and high-quality option for a variety of welding applications. The role of wholesale suppliers in providing this essential material cannot be overstated, as they help to ensure that businesses can operate efficiently and effectively. When selecting a manufacturer, it is crucial to consider factors like quality control, reputation, product range, customer service, and technical support. By focusing on these key aspects, welding professionals can ensure they are well-equipped to meet the demands of their projects, ultimately leading to successful and high-quality welding results.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025