Қаң . 21, 2025 02:58

Back to list

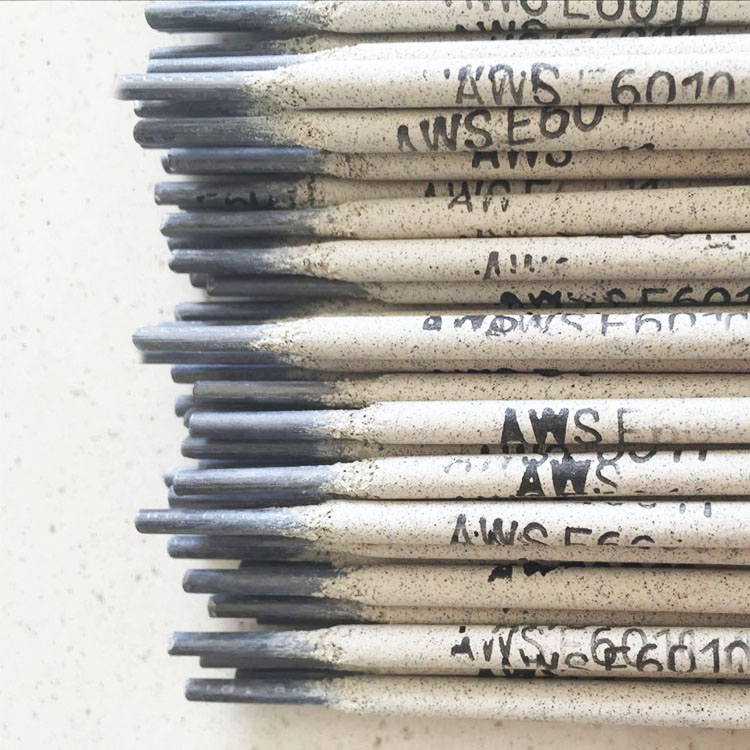

7018 welding rods electrodes

Choosing the right welding electrode is crucial for achieving superior welds, especially when dealing with demanding materials or conditions. Among various types, the 2.5mm welding electrodes 7018 stands out for specific applications, combining robust features to meet industry standards.

Authoritativeness in welding demands respecting standards and certifications recognized worldwide. The 7018 electrode complies with American Welding Society (AWS) specifications, reassuring users of its adherence to stringent performance criteria. In high-stakes environments, such endorsements are not mere formalities but reflect a track record of dependable performance. Trustworthiness is another cornerstone attribute. Through rigorous testing and real-time feedback from seasoned professionals, the 7018 electrode consistently meets expectations. Stories from the field illustrate instances where welders have relied on these electrodes to meet deadlines and surpass inspection criteria, underscoring their dependability. Overall, the 2.5mm welding electrodes 7018 blend practicality with proficiency. Their adaptability across a spectrum of projects ensures they remain a staple in a welder's toolkit. By choosing this particular electrode, professionals not only align their work with best practices but also reinforce the trusted craftsmanship that the welding community demands. For those striving to deliver outstanding welds, paying attention to the specificities of electrode choice is paramount. The 2.5mm 7018 stands as a testament to what modern welding technology can achieve—precision, strength, and reliability rolled into one, an undisputed ally in the journey from challenge to achievement.

Authoritativeness in welding demands respecting standards and certifications recognized worldwide. The 7018 electrode complies with American Welding Society (AWS) specifications, reassuring users of its adherence to stringent performance criteria. In high-stakes environments, such endorsements are not mere formalities but reflect a track record of dependable performance. Trustworthiness is another cornerstone attribute. Through rigorous testing and real-time feedback from seasoned professionals, the 7018 electrode consistently meets expectations. Stories from the field illustrate instances where welders have relied on these electrodes to meet deadlines and surpass inspection criteria, underscoring their dependability. Overall, the 2.5mm welding electrodes 7018 blend practicality with proficiency. Their adaptability across a spectrum of projects ensures they remain a staple in a welder's toolkit. By choosing this particular electrode, professionals not only align their work with best practices but also reinforce the trusted craftsmanship that the welding community demands. For those striving to deliver outstanding welds, paying attention to the specificities of electrode choice is paramount. The 2.5mm 7018 stands as a testament to what modern welding technology can achieve—precision, strength, and reliability rolled into one, an undisputed ally in the journey from challenge to achievement.

Previous:

Latest news

-

Best Hardfacing MIG Wire for Sale High Durability Welding SuppliesNewsJun.10,2025

-

ER70S-6 MIG Welding Wire Supplier High Quality China Welding Wire ManufacturerNewsJun.10,2025

-

Premium Aluminum Flux Core Wire China Manufacturer FactoryNewsJun.10,2025

-

Premium Cast Iron Welding Electrodes for Superior BondsNewsJun.10,2025

-

Premium 309L MIG Wire High Strength & Corrosion ResistantNewsJun.10,2025

-

Stainless Steel Welding Rod Types Complete Guide to Corrosion ResistanceNewsJun.09,2025