Leading Manufacturer of 316 Stainless Steel Welding Rods for Superior Welding Results

A Comprehensive Overview of 316 Stainless Steel Welding Rod Manufacturers

The world of welding is vast and multifaceted, with numerous applications across various industries. Among the most significant materials used in welding is stainless steel, known for its durability, corrosion resistance, and strength. One of the most sought-after grades in stainless steel welding is 316. This article seeks to provide an in-depth understanding of 316 stainless steel welding rod manufacturers, their products, and their importance in the welding industry.

Understanding 316 Stainless Steel

316 stainless steel is often referred to as marine-grade stainless steel due to its excellent resistance to corrosion in harsh environments, particularly those involving saltwater. Composed primarily of iron, chromium, nickel, and molybdenum, 316 is known for its ability to withstand higher temperatures and is often utilized in applications like chemical processing, marine applications, and food processing.

The Role of Welding Rods

Welding rods serve as a crucial component in the welding process; they provide the filler metal that joins two pieces of metal together. For stainless steel, welding rods made from the same grade of material are typically used to ensure compatibility and strength in the weld joint. The 316 stainless steel welding rod is specifically engineered to maintain the properties of 316 stainless steel, ensuring robust and corrosion-resistant welds.

Identifying Quality Manufacturers

When searching for 316 stainless steel welding rods, it’s essential to identify reputable manufacturers. Quality can significantly impact the outcome of a welding project, as inferior rods can lead to weakened joints and decreased corrosion resistance. Here are a few factors to consider when evaluating welding rod manufacturers

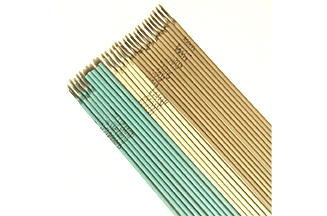

316 welding rod manufacturer

2. Material Composition Confirm that the welding rods meet the specific chemical composition of 316 stainless steel. This ensures that the welds will have the desired properties.

3. Reputation and Experience Established manufacturers often have a track record of producing reliable products. Research customer reviews and industry reputation.

4. Range of Products A good manufacturer will offer a variety of welding rods tailored to different welding techniques, whether it’s MIG, TIG, or stick welding.

5. Customer Support and Service Consider manufacturers that provide excellent customer service, including technical support and guidance on selecting the right products for your specific needs.

Leading Manufacturers in the Market

Several well-known manufacturers specialize in 316 stainless steel welding rods. Companies like Lincoln Electric, ESAB, and Miller Electric are renowned for their high-quality welding products, including rods designed for stainless steel applications. These manufacturers invest in research and development to ensure their products meet the evolving needs of the industry.

Conclusion

In conclusion, 316 stainless steel welding rods are vital components in numerous applications across various industries, particularly where corrosion resistance and strength are essential. Finding a reputable manufacturer is crucial for achieving high-quality welds that enhance the durability and longevity of projects. By considering factors such as certifications, material composition, reputation, product range, and customer support, buyers can make informed decisions when selecting their welding rods. As industries continue to grow and evolve, the demand for quality welding materials will remain a priority, making the role of 316 stainless steel welding rod manufacturers increasingly significant in the welding landscape.

-

Best MIG Welding No Gas Flux Core Solution – Easy, Portable & Clean WeldingNewsJul.08,2025

-

7018 Welding Rod 3/16 - High Strength, Low Hydrogen Electrodes Wholesale 3/32 Welding Rod 7018 Suppliers & China 7018 AC Welding Rod FactoryNewsJul.08,2025

-

High Quality MIG Aluminium Welding Wire - Wholesale Factory Prices from China SuppliersNewsJul.07,2025

-

High-Quality Gasless Aluminum Welding Wire China Gasless Aluminum MIG Wire SupplierNewsJul.07,2025

-

High Quality Ordinary Welding Rod for Pipes – Reliable China Welding Rod 7016 SupplierNewsJul.06,2025

-

Welding Wire 0.9 mm ER70S-6 Supplier Wholesale Manufacturers & FactoriesNewsJul.06,2025