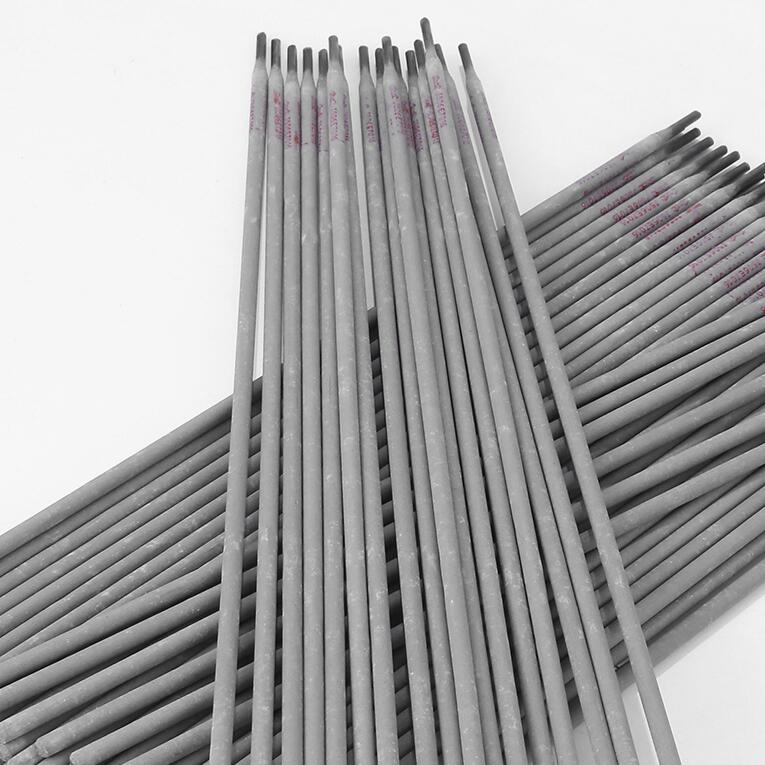

3.2mm Welding Rods Supplier for Quality Welding Applications and Services

The Evolution of 3.2mm Welding Rods A Manufacturer's Perspective

In the world of welding, the choice of welding rods plays a crucial role in determining the quality of the final product. Among various options available, 3.2mm welding rods have gained remarkable popularity due to their versatility, durability, and efficiency. As a manufacturer specializing in these rods, it is essential to understand the intricacies involved in their production, performance characteristics, and their applications across different industries.

Understanding Welding Rods

Welding rods are consumable electrodes that provide the filler material needed for welding processes. Typically used in electric arc welding, the 3.2mm diameter rods are especially favored due to their compatibility with a wide range of welding techniques including MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and SMAW (Shielded Metal Arc Welding). The 3.2mm thickness provides an ideal balance between ease of handling and the structural integrity of the weld, making them suitable for both thin and thick materials.

Manufacturing Process

The production of 3.2mm welding rods involves several meticulous steps that ensure high quality and performance. Initially, raw materials, predominantly mild steel, are selected and prepared. The steel is processed to achieve the desired chemical composition, which influences the rod’s strength and weldability.

Next, the welding rods are produced through a process called extrusion or drawing. This process allows for consistent diameter and uniformity with minimal defects. After the initial shaping, the rods undergo heat treatment to enhance their mechanical properties, such as tensile strength and ductility. This ensures that the rods can withstand the intense heat and mechanical stress experienced during the welding process.

Once the rods are fabricated, they are coated with a protective flux. This flux not only stabilizes the arc but also protects the weld puddle from atmospheric contamination, ensuring a clean and strong weld. The coating process is critical, as it directly affects the usability and effectiveness of the welding rods.

3.2mm welding rods manufacturer

Quality Control

As a manufacturer, quality control is paramount in the production of 3.2mm welding rods. Each batch is subjected to rigorous testing procedures, including tensile strength tests, microstructure analysis, and weldability assessments. Compliance with international standards such as ISO and AWS ensures that the welding rods meet the highest quality benchmarks, thereby gaining the confidence of end-users.

Applications

The versatility of 3.2mm welding rods allows them to be used across various sectors including automotive, construction, shipbuilding, and manufacturing. In the automotive industry, for instance, these rods are used for joining components with precision and strength. In construction, they play a pivotal role in the fabrication of structural elements where durability is essential.

Moreover, the demand for 3.2mm welding rods is on the rise due to the growth of advanced manufacturing technologies and the increasing emphasis on high-strength materials. Their suitability for both indoor and outdoor applications makes them a favorite among welders across different environments.

Conclusion

The journey of 3.2mm welding rods from raw materials to finished products is a testament to the intricate processes involved in welding rod manufacturing. As a manufacturer, our commitment to quality, innovation, and customer satisfaction has positioned us as a reliable source for welding solutions. With ongoing advancements in technology and an ever-increasing range of applications, the future of 3.2mm welding rods looks promising, holding the potential to meet the evolving demands of various industries worldwide. Investing in better production techniques and striving for excellence will ensure that we continue to deliver top-notch products that exceed the expectations of our customers and contribute to the success of their projects.

-

AWS E6013 Welding Electrodes: All-Position & Smooth Arc RodsNewsAug.25,2025

-

E312 Electrode: High Strength Welding Rod for Dissimilar MetalsNewsAug.24,2025

-

J506 Welding Rod: High-Strength, Crack-Resistant ElectrodeNewsAug.23,2025

-

E71T-1 Shielding Gas for Superior Welding Quality & EfficiencyNewsAug.22,2025

-

E316L Welding Rod: Premium 316L Stainless Steel WeldsNewsAug.11,2025

-

Premium SG2 Welding Wire | High-Quality MIG/MAG for SteelNewsAug.10,2025